Labor-intensive assembly requires skilled workers to manually handle intricate tasks, which often results in higher labor costs and longer production times. Machine-assisted assembly enhances efficiency by automating repetitive processes, reducing human error and increasing overall output quality. Choosing the right method depends on the complexity of the product, volume requirements, and budget constraints.

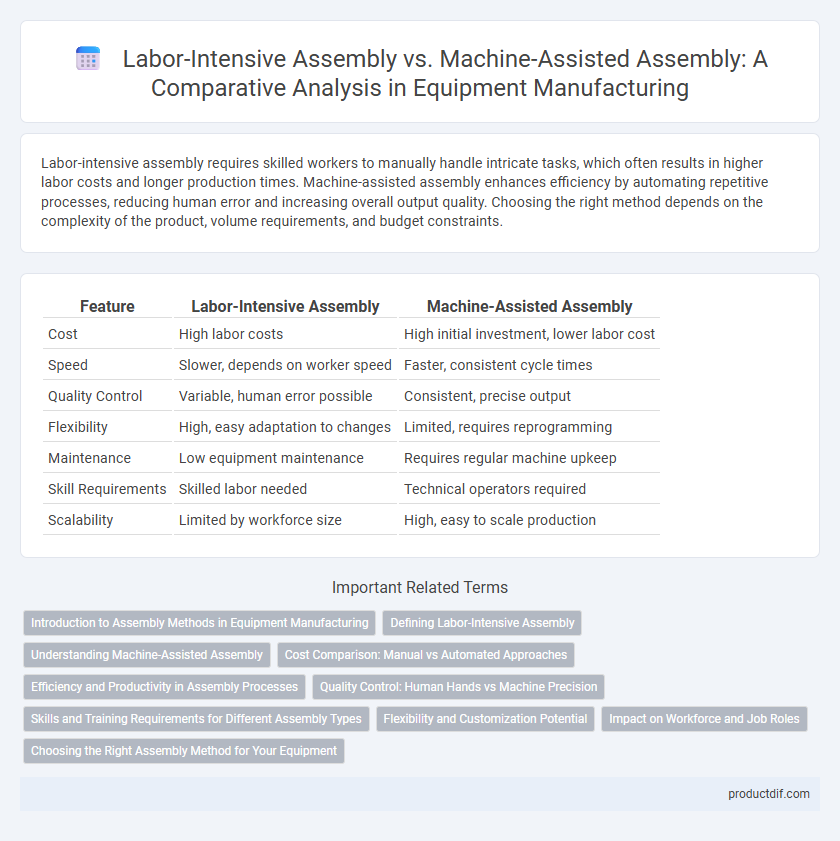

Table of Comparison

| Feature | Labor-Intensive Assembly | Machine-Assisted Assembly |

|---|---|---|

| Cost | High labor costs | High initial investment, lower labor cost |

| Speed | Slower, depends on worker speed | Faster, consistent cycle times |

| Quality Control | Variable, human error possible | Consistent, precise output |

| Flexibility | High, easy adaptation to changes | Limited, requires reprogramming |

| Maintenance | Low equipment maintenance | Requires regular machine upkeep |

| Skill Requirements | Skilled labor needed | Technical operators required |

| Scalability | Limited by workforce size | High, easy to scale production |

Introduction to Assembly Methods in Equipment Manufacturing

Labor-intensive assembly in equipment manufacturing relies heavily on skilled manual labor, enabling flexibility for complex or customized products but often resulting in slower production rates and higher labor costs. Machine-assisted assembly integrates automated tools and machinery to enhance precision, consistency, and speed, making it suitable for high-volume manufacturing with repetitive tasks. Selecting the optimal assembly method depends on factors such as product complexity, production scale, cost efficiency, and desired quality standards.

Defining Labor-Intensive Assembly

Labor-intensive assembly involves manual processes where workers perform tasks with minimal mechanization, relying heavily on human skills and dexterity. This method often requires more time and labor costs but allows for greater flexibility in handling complex or customized products. The emphasis on human involvement contrasts with machine-assisted assembly, which integrates automation to improve speed and consistency.

Understanding Machine-Assisted Assembly

Machine-assisted assembly integrates automated tools and robotic systems to enhance precision, speed, and consistency in manufacturing processes. This approach minimizes human error and reduces manual labor, resulting in higher throughput and improved product quality. Advanced sensors and programmable controllers coordinate complex tasks, optimizing efficiency and enabling scalable production lines.

Cost Comparison: Manual vs Automated Approaches

Labor-intensive assembly incurs higher operational costs due to wages, training, and slower production rates, making it less cost-effective for large-scale manufacturing. Machine-assisted assembly reduces labor expenses, increases throughput, and enhances precision, resulting in lower per-unit costs despite higher initial capital investment. Evaluating total cost of ownership reveals automated approaches provide better long-term financial benefits through scalability and efficiency improvements.

Efficiency and Productivity in Assembly Processes

Labor-intensive assembly relies heavily on manual labor, leading to slower production rates and higher susceptibility to human error, which can decrease overall efficiency. Machine-assisted assembly integrates automated tools and robotics, significantly boosting productivity by reducing cycle times and ensuring consistent quality in high-volume manufacturing. Optimizing assembly processes through machine assistance enhances throughput while minimizing labor costs and operational downtime.

Quality Control: Human Hands vs Machine Precision

Labor-intensive assembly relies on skilled human hands, allowing for nuanced quality control through sensory feedback and manual adjustments, which is crucial for complex or custom products. Machine-assisted assembly delivers consistent precision and repeatability, reducing human error and ensuring uniform quality across large production volumes. Combining both approaches can optimize quality control by leveraging human judgment alongside mechanical accuracy.

Skills and Training Requirements for Different Assembly Types

Labor-intensive assembly demands higher manual dexterity and extensive hands-on training to ensure precision and quality, often relying on skilled workers adept at detailed tasks. In contrast, machine-assisted assembly requires operators to have technical knowledge for programming, operating, and maintaining automated systems, emphasizing proficiency in troubleshooting and system integration. Both assembly types necessitate continuous skill development, but machine-assisted processes prioritize technical training in robotics and automation, while labor-intensive methods focus on craftsmanship and repetitive task expertise.

Flexibility and Customization Potential

Labor-intensive assembly offers higher flexibility and customization potential, allowing workers to adapt processes for unique or small-batch products with ease. Machine-assisted assembly excels in consistent output and speed but often requires extensive reprogramming or tooling changes for new product variations. Choosing between these methods depends on the balance between production volume demands and the need for personalized or complex product configurations.

Impact on Workforce and Job Roles

Labor-intensive assembly relies heavily on manual skills, increasing demand for skilled labor and offering more job opportunities but often leading to slower production rates. Machine-assisted assembly reduces repetitive tasks and physical strain, shifting workforce roles toward machine operation and maintenance, which requires technical expertise. The transition impacts workforce dynamics by necessitating reskilling and creating a higher need for technological proficiency in job roles.

Choosing the Right Assembly Method for Your Equipment

Selecting the right assembly method for your equipment depends on factors such as production volume, complexity, and cost efficiency. Labor-intensive assembly suits low-volume, highly customized products requiring skilled craftsmanship, while machine-assisted assembly optimizes high-volume, repetitive tasks for faster output and consistent quality. Evaluating operational goals, workforce capabilities, and long-term maintenance costs ensures optimal alignment with your production strategy.

Labor-Intensive Assembly vs Machine-Assisted Assembly Infographic

productdif.com

productdif.com