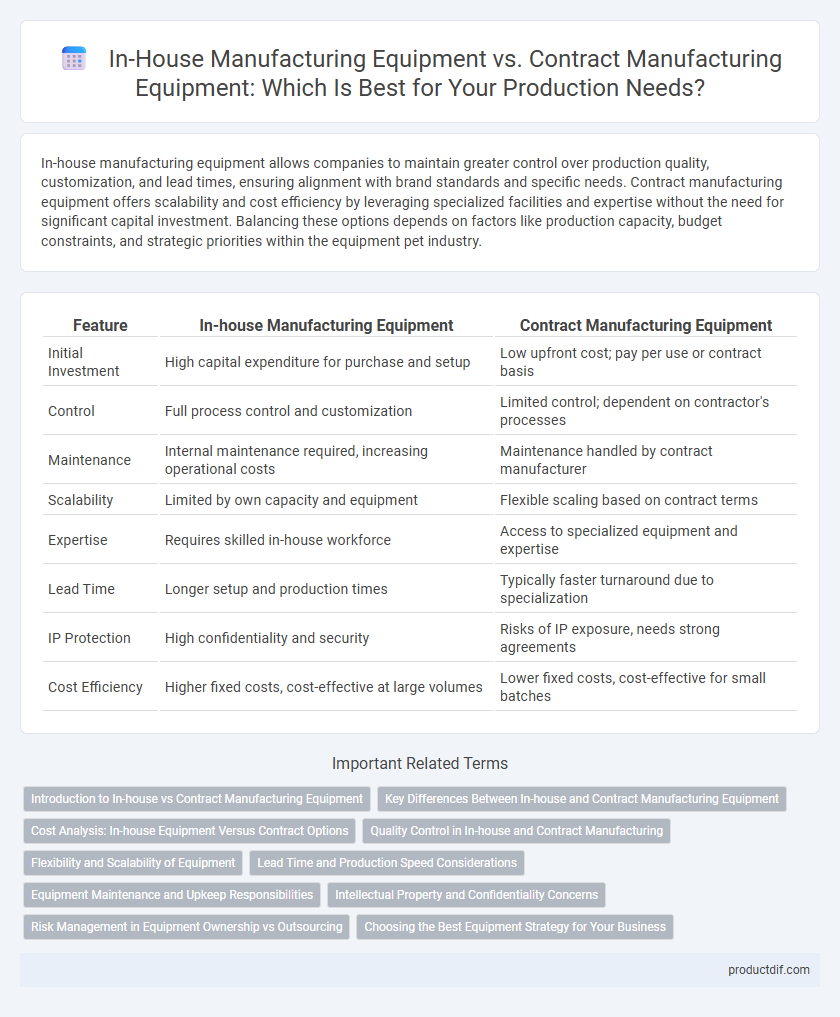

In-house manufacturing equipment allows companies to maintain greater control over production quality, customization, and lead times, ensuring alignment with brand standards and specific needs. Contract manufacturing equipment offers scalability and cost efficiency by leveraging specialized facilities and expertise without the need for significant capital investment. Balancing these options depends on factors like production capacity, budget constraints, and strategic priorities within the equipment pet industry.

Table of Comparison

| Feature | In-house Manufacturing Equipment | Contract Manufacturing Equipment |

|---|---|---|

| Initial Investment | High capital expenditure for purchase and setup | Low upfront cost; pay per use or contract basis |

| Control | Full process control and customization | Limited control; dependent on contractor's processes |

| Maintenance | Internal maintenance required, increasing operational costs | Maintenance handled by contract manufacturer |

| Scalability | Limited by own capacity and equipment | Flexible scaling based on contract terms |

| Expertise | Requires skilled in-house workforce | Access to specialized equipment and expertise |

| Lead Time | Longer setup and production times | Typically faster turnaround due to specialization |

| IP Protection | High confidentiality and security | Risks of IP exposure, needs strong agreements |

| Cost Efficiency | Higher fixed costs, cost-effective at large volumes | Lower fixed costs, cost-effective for small batches |

Introduction to In-house vs Contract Manufacturing Equipment

In-house manufacturing equipment offers companies direct control over production processes, enabling customization and faster iteration cycles. Contract manufacturing equipment, managed by third-party providers, allows businesses to scale operations without significant capital investment in machinery. Choosing between these options depends on factors like production volume, cost efficiency, quality control, and strategic flexibility.

Key Differences Between In-house and Contract Manufacturing Equipment

In-house manufacturing equipment offers greater control over production processes, customization, and maintenance schedules, enabling rapid adjustments to product specifications. Contract manufacturing equipment, typically standardized and managed by external vendors, reduces capital expenditure and operational complexity but may limit flexibility and proprietary technology integration. The key differences lie in ownership, control, cost implications, and scalability of equipment use, impacting overall manufacturing efficiency and product quality.

Cost Analysis: In-house Equipment Versus Contract Options

In-house manufacturing equipment requires significant upfront capital investment, including purchase, maintenance, and operational costs, which can increase fixed expenses but offer long-term control and potential cost savings. Contract manufacturing equipment typically involves variable costs through outsourcing fees, reducing initial capital expenditure but potentially increasing per-unit costs due to service markups and less operational control. A detailed cost analysis must weigh depreciation, labor, overhead, and scalability against the flexibility and reduced financial risk of contract manufacturing to determine the most cost-effective option.

Quality Control in In-house and Contract Manufacturing

In-house manufacturing equipment allows for direct oversight and stringent quality control protocols, ensuring that production standards consistently meet company specifications. Contract manufacturing equipment relies on third-party facilities, which can introduce variability in quality control practices and require thorough audits to maintain product integrity. Implementing robust quality assurance systems in both settings is essential to minimize defects and comply with industry regulations.

Flexibility and Scalability of Equipment

In-house manufacturing equipment offers higher flexibility allowing quick adjustments to production processes and customization for specific products, facilitating rapid response to market changes. Contract manufacturing equipment, while generally scalable due to shared resources and larger operational capacity, may limit flexibility because equipment is standardized to serve multiple clients' needs. Choosing between in-house and contract manufacturing equipment requires balancing the priority of adaptable production capabilities against the advantage of scalable output to meet fluctuating demand.

Lead Time and Production Speed Considerations

In-house manufacturing equipment offers greater control over lead time and production speed, enabling rapid adjustments and faster turnaround for custom orders. Contract manufacturing equipment may involve longer lead times due to external scheduling and coordination but can provide high-speed production capabilities through specialized machinery. Evaluating the balance between immediate availability and production efficiency is crucial when choosing between in-house and contract manufacturing solutions.

Equipment Maintenance and Upkeep Responsibilities

In-house manufacturing equipment requires dedicated internal teams for regular maintenance, calibration, and timely repairs to ensure optimal performance and minimize downtime. Contract manufacturing equipment maintenance responsibilities are typically outlined in service agreements, placing the onus on the contract manufacturer to manage upkeep, thus reducing the client's operational burden. Clear communication and well-defined Service Level Agreements (SLAs) are essential to guarantee consistent equipment reliability and compliance with industry standards in contract manufacturing environments.

Intellectual Property and Confidentiality Concerns

In-house manufacturing equipment offers greater control over intellectual property by keeping proprietary processes and designs internal, minimizing risks of data leaks and unauthorized use. Contract manufacturing equipment often necessitates sharing sensitive information with third parties, raising concerns over confidentiality breaches and potential IP misappropriation. Implementing robust non-disclosure agreements and secure data handling protocols is critical when outsourcing to safeguard intellectual property effectively.

Risk Management in Equipment Ownership vs Outsourcing

In-house manufacturing equipment requires significant capital investment and ongoing maintenance, exposing companies to risks such as equipment downtime and technological obsolescence, which can disrupt production schedules. Contract manufacturing equipment transfers these operational risks to third-party suppliers, reducing direct asset management but increasing dependency on external quality control and supply chain reliability. Effective risk management balances control over proprietary processes with mitigating financial and operational uncertainties associated with equipment ownership versus outsourcing.

Choosing the Best Equipment Strategy for Your Business

Selecting the optimal equipment strategy hinges on evaluating cost-efficiency, control over production quality, and scalability potential. In-house manufacturing equipment offers direct oversight and customization capabilities, ideal for companies prioritizing product innovation and proprietary processes. Contract manufacturing equipment provides flexibility, reduced capital expenditure, and access to specialized technologies, benefiting businesses focused on rapid market entry and reducing operational risks.

In-house Manufacturing Equipment vs Contract Manufacturing Equipment Infographic

productdif.com

productdif.com