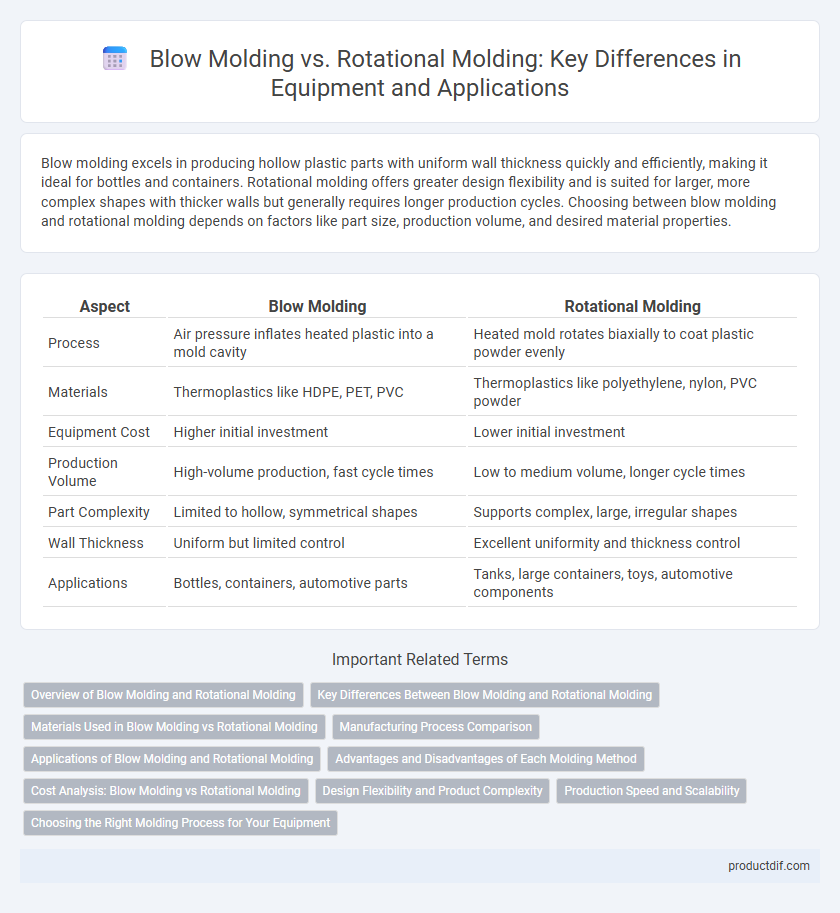

Blow molding excels in producing hollow plastic parts with uniform wall thickness quickly and efficiently, making it ideal for bottles and containers. Rotational molding offers greater design flexibility and is suited for larger, more complex shapes with thicker walls but generally requires longer production cycles. Choosing between blow molding and rotational molding depends on factors like part size, production volume, and desired material properties.

Table of Comparison

| Aspect | Blow Molding | Rotational Molding |

|---|---|---|

| Process | Air pressure inflates heated plastic into a mold cavity | Heated mold rotates biaxially to coat plastic powder evenly |

| Materials | Thermoplastics like HDPE, PET, PVC | Thermoplastics like polyethylene, nylon, PVC powder |

| Equipment Cost | Higher initial investment | Lower initial investment |

| Production Volume | High-volume production, fast cycle times | Low to medium volume, longer cycle times |

| Part Complexity | Limited to hollow, symmetrical shapes | Supports complex, large, irregular shapes |

| Wall Thickness | Uniform but limited control | Excellent uniformity and thickness control |

| Applications | Bottles, containers, automotive parts | Tanks, large containers, toys, automotive components |

Overview of Blow Molding and Rotational Molding

Blow molding is a manufacturing process that involves inflating heated plastic into a mold cavity to create hollow objects such as bottles and containers, known for its efficiency in producing high-volume, uniform products. Rotational molding uses a heated mold that rotates along two axes, allowing molten plastic to coat the interior and form large, hollow, and complex shapes with uniform wall thickness. While blow molding excels in speed and precision for thin-walled items, rotational molding offers greater design flexibility and is ideal for low-volume or oversized parts.

Key Differences Between Blow Molding and Rotational Molding

Blow molding produces hollow plastic parts through inflation of a heated parison within a mold, ideal for high-volume, lightweight bottles and containers. Rotational molding involves heating and rotating a mold to evenly coat the interior with plastic, enabling the creation of thicker, seamless, and large hollow parts with complex shapes. Key differences include production speed, cost efficiency, wall thickness uniformity, and ideal product applications, with blow molding excelling in fast, mass production and rotational molding suited for durable, low-volume, larger items.

Materials Used in Blow Molding vs Rotational Molding

Blow molding primarily uses thermoplastics like polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC) due to their ability to soften and stretch when heated, allowing for hollow, lightweight products such as bottles and containers. Rotational molding utilizes powdered or liquid thermoplastic resins, often polyethylene, polyethylene copolymers, and sometimes nylon or PVC, which evenly coat the mold's interior to create durable, seamless, and thick-walled parts ideal for tanks, kayaks, and large containers. The difference in material form--pellets for blow molding versus powders for rotational molding--directly impacts processing methods and final product properties.

Manufacturing Process Comparison

Blow molding uses compressed air to inflate heated plastic into a mold cavity, enabling fast production of hollow parts with uniform wall thickness, ideal for containers and bottles. Rotational molding involves heating resin in a rotating mold along two axes, producing large, seamless, and stress-free hollow parts with thicker walls. Blow molding offers higher output rates and precision, while rotational molding excels in complex shapes and cost-effective small batch production.

Applications of Blow Molding and Rotational Molding

Blow molding is primarily used for manufacturing hollow plastic products such as bottles, containers, and automotive parts with uniform wall thickness and high production efficiency. Rotational molding excels in creating large, complex, and hollow items like tanks, kayaks, and playground equipment with low tooling costs and minimal material waste. Both processes serve distinct industries, with blow molding favored in packaging and rotational molding preferred for custom, durable, and low-volume applications.

Advantages and Disadvantages of Each Molding Method

Blow molding offers rapid production speeds and excellent surface finishes, making it ideal for hollow plastic parts like bottles; however, it is limited in part complexity and wall thickness consistency. Rotational molding excels in producing large, complex-shaped items with uniform wall thickness and minimal stress, but the process is slower and less suitable for high-volume manufacturing. Both methods require specific equipment investments and material considerations, with blow molding favoring thermoplastics and rotational molding accommodating a wider range of resins.

Cost Analysis: Blow Molding vs Rotational Molding

Blow molding generally offers lower initial tooling costs and faster production cycles compared to rotational molding, making it cost-effective for high-volume manufacturing of hollow plastic parts. Rotational molding has higher tooling expenses but lower material waste and energy consumption, which benefits low to medium production volumes and larger, more complex geometries. Evaluating cost analysis between blow molding and rotational molding depends on factors such as production volume, design complexity, and material requirements, impacting overall manufacturing expenses.

Design Flexibility and Product Complexity

Blow molding offers high design flexibility for hollow products with uniform wall thickness, enabling complex shapes and detailed features suitable for containers and bottles. Rotational molding excels in producing large, hollow parts with variable wall thickness, accommodating intricate internal geometries and multi-layer designs ideal for tanks and automotive components. Both methods provide distinct advantages in product complexity, with blow molding favoring speed and precision while rotational molding supports durable, stress-free structures.

Production Speed and Scalability

Blow molding offers high production speeds with the capability to produce thousands of uniform parts per hour, making it ideal for large-scale manufacturing. Rotational molding has slower cycle times, typically ranging from 10 to 40 minutes per part, which limits its scalability for mass production. For businesses prioritizing fast output and large volume, blow molding provides significant advantages over rotational molding.

Choosing the Right Molding Process for Your Equipment

Blow molding offers high production speed and is ideal for manufacturing hollow plastic parts with uniform wall thickness, making it suitable for bottles and containers. Rotational molding provides greater design flexibility and thicker walls at a lower tooling cost, perfect for large, complex shapes such as tanks and kayaks. Selecting between blow molding and rotational molding depends on your equipment's production volume, part complexity, and material requirements to optimize efficiency and cost-effectiveness.

Blow molding vs Rotational molding Infographic

productdif.com

productdif.com