Pre-assembled kits offer streamlined setup with all components tested and ready for immediate use, minimizing errors and saving time. DIY kits provide customization flexibility and hands-on experience, appealing to users who enjoy assembling equipment and tailoring features. Choosing between these options depends on balancing convenience versus personalization and technical skill.

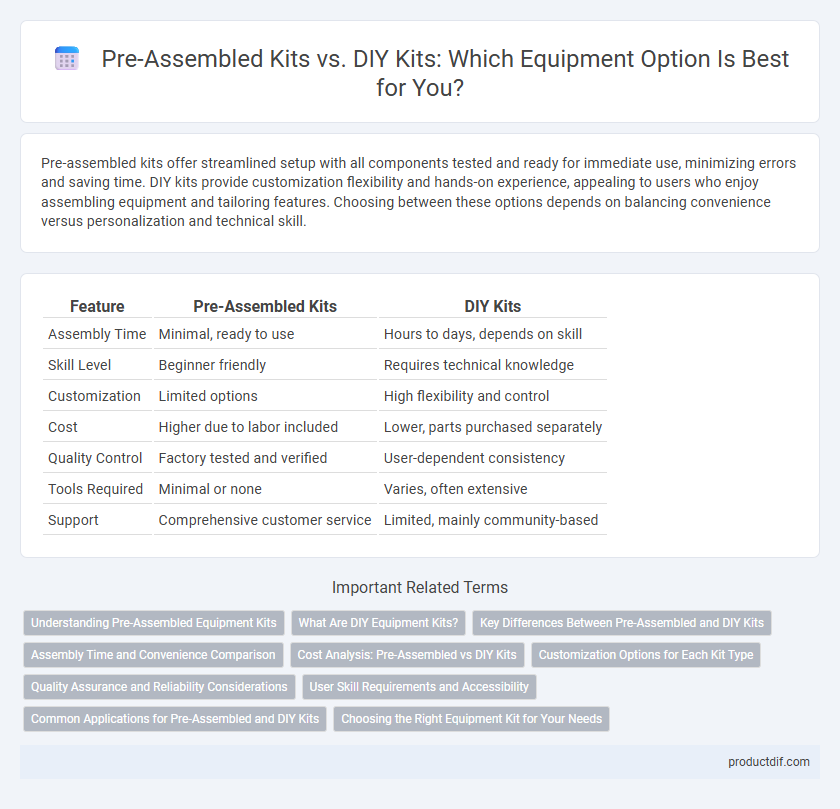

Table of Comparison

| Feature | Pre-Assembled Kits | DIY Kits |

|---|---|---|

| Assembly Time | Minimal, ready to use | Hours to days, depends on skill |

| Skill Level | Beginner friendly | Requires technical knowledge |

| Customization | Limited options | High flexibility and control |

| Cost | Higher due to labor included | Lower, parts purchased separately |

| Quality Control | Factory tested and verified | User-dependent consistency |

| Tools Required | Minimal or none | Varies, often extensive |

| Support | Comprehensive customer service | Limited, mainly community-based |

Understanding Pre-Assembled Equipment Kits

Pre-assembled equipment kits offer a streamlined solution by including all components pre-fitted and tested for immediate use, reducing setup time and the risk of assembly errors. These kits are especially beneficial in industrial and commercial settings where time efficiency and reliability are critical. Understanding the specifications and compatibility of pre-assembled kits ensures optimal performance and minimizes downtime compared to DIY kits.

What Are DIY Equipment Kits?

DIY equipment kits consist of individual components and detailed instructions that allow users to assemble tools or machinery themselves, promoting customization and hands-on learning. These kits typically include parts such as screws, brackets, wiring, and user manuals but require technical knowledge and time investment for proper assembly. Choosing DIY kits encourages skill development and can be cost-effective compared to pre-assembled equipment, but demands patience and precision to ensure functional and safe end products.

Key Differences Between Pre-Assembled and DIY Kits

Pre-assembled kits provide fully constructed equipment components, ensuring immediate usability and consistent quality control, while DIY kits require manual assembly, offering customization and hands-on experience for users. Pre-assembled kits typically reduce setup time and potential errors, ideal for those prioritizing convenience, whereas DIY kits promote learning and flexibility but demand technical skills and patience. Choosing between these options depends on the user's expertise level, project complexity, and desired level of involvement in the equipment assembly process.

Assembly Time and Convenience Comparison

Pre-assembled kits significantly reduce assembly time by providing all components pre-fitted, ensuring quick and hassle-free setup ideal for users with limited technical skills. DIY kits require more time and effort due to individual part assembly, appealing to enthusiasts seeking customization and hands-on experience. Convenience favors pre-assembled kits, offering faster installation and reduced errors, whereas DIY kits prioritize flexibility and cost savings at the expense of longer build durations.

Cost Analysis: Pre-Assembled vs DIY Kits

Pre-assembled kits often carry higher upfront costs due to labor and assembly expenses, while DIY kits tend to be more budget-friendly, offering savings by requiring user effort and time. Cost analysis must factor in potential hidden expenses such as tools, error correction, and learning curves inherent in DIY projects. Evaluating total cost of ownership including assembly time, accuracy, and potential rework is essential to determine the most economical option.

Customization Options for Each Kit Type

Pre-assembled kits offer limited customization options, typically providing fixed components designed for specific purposes, ensuring ease of installation and consistent performance. DIY kits allow extensive customization, enabling users to select, modify, or upgrade individual parts to meet specific requirements or preferences. The choice between kits depends on the balance between convenience and the need for tailored equipment configurations.

Quality Assurance and Reliability Considerations

Pre-assembled kits typically undergo rigorous quality assurance processes, ensuring all components meet industry standards for reliability and performance. DIY kits rely on user assembly, which can introduce variability in build quality and potential errors affecting the final equipment's durability and safety. Manufacturers of pre-assembled kits often conduct comprehensive testing and certification, providing greater consistency and confidence for critical equipment applications.

User Skill Requirements and Accessibility

Pre-assembled kits require minimal technical skills, making them accessible to beginners and users seeking quick setup. DIY kits demand higher user proficiency in assembly and troubleshooting, appealing to experienced hobbyists or professionals. Accessibility varies as pre-assembled kits reduce installation time, while DIY kits offer customization but may pose challenges to those with limited skills.

Common Applications for Pre-Assembled and DIY Kits

Pre-assembled kits are commonly used in industrial settings, medical equipment, and consumer electronics where reliability and quick deployment are critical. DIY kits often find applications in educational projects, hobbyist robotics, and custom home automation systems due to their flexibility and customization options. Both kit types serve essential roles in prototyping, repair, and product development across various equipment sectors.

Choosing the Right Equipment Kit for Your Needs

Selecting the right equipment kit depends on your skill level, project complexity, and time constraints. Pre-assembled kits offer convenience and reliability with tested components, ideal for beginners or those needing quick setup. DIY kits provide customization and hands-on experience, better suited for experienced users seeking tailored solutions and deeper understanding.

Pre-assembled kits vs DIY kits Infographic

productdif.com

productdif.com