A soldering station offers precise control for manual electronic component assembly, ideal for small-scale repairs and prototyping. A reflow oven provides consistent, high-volume soldering by evenly melting solder paste on PCB surfaces for mass production. Choosing between them depends on the complexity, volume, and precision needs of the soldering task.

Table of Comparison

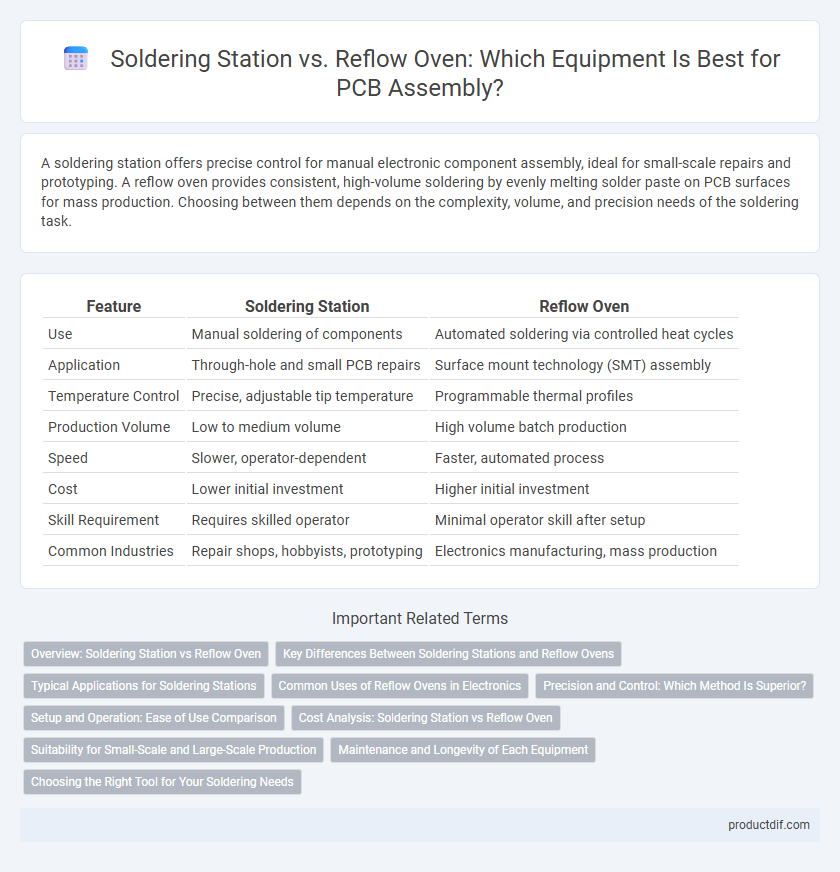

| Feature | Soldering Station | Reflow Oven |

|---|---|---|

| Use | Manual soldering of components | Automated soldering via controlled heat cycles |

| Application | Through-hole and small PCB repairs | Surface mount technology (SMT) assembly |

| Temperature Control | Precise, adjustable tip temperature | Programmable thermal profiles |

| Production Volume | Low to medium volume | High volume batch production |

| Speed | Slower, operator-dependent | Faster, automated process |

| Cost | Lower initial investment | Higher initial investment |

| Skill Requirement | Requires skilled operator | Minimal operator skill after setup |

| Common Industries | Repair shops, hobbyists, prototyping | Electronics manufacturing, mass production |

Overview: Soldering Station vs Reflow Oven

A soldering station provides precise manual control for individual electronic components, ideal for small-scale or repair work with temperatures reaching up to 480degC. Reflow ovens automate the soldering process by uniformly heating entire printed circuit boards (PCBs), efficiently handling mass production with temperature profiles tailored for various solder pastes. Choosing between a soldering station and a reflow oven depends on production volume, component complexity, and process repeatability requirements.

Key Differences Between Soldering Stations and Reflow Ovens

Soldering stations provide precision manual control for assembling or repairing electronic components, ideal for small-scale or detailed tasks, while reflow ovens automate the soldering process for mass production, ensuring consistent thermal profiles across entire circuit boards. Key differences include temperature control methods--soldering stations use adjustable soldering irons with quick heating, whereas reflow ovens employ conveyor systems and programmable thermal cycles for uniform solder melting. Workflow efficiency and application scale also distinguish these tools, with soldering stations suited for prototyping and rework, and reflow ovens optimized for high-volume manufacturing environments.

Typical Applications for Soldering Stations

Soldering stations are typically used for precision tasks such as electronic circuit board repairs, prototype assembly, and small batch production where manual control is essential. They provide adjustable temperature control and fine-tip soldering capability, making them ideal for delicate components and detailed work. These stations are preferred in educational settings, DIY projects, and maintenance labs due to their versatility and ease of use.

Common Uses of Reflow Ovens in Electronics

Reflow ovens are primarily used in surface-mount technology (SMT) to solder electronic components onto printed circuit boards (PCBs) with precise temperature control. They ensure uniform heating, enabling consistent melting and solidification of solder paste for reliable electrical connections in mass production. Common applications include assembling complex multi-layer PCBs in consumer electronics, automotive systems, and telecommunications devices.

Precision and Control: Which Method Is Superior?

Soldering stations offer superior precision and control for intricate electronic components, allowing technicians to manually adjust temperature and apply solder exactly where needed. Reflow ovens excel in consistent heat distribution for mass production but lack the fine-tuned control required for delicate corrections or small-scale tasks. For applications demanding meticulous precision, soldering stations provide unmatched accuracy compared to the more automated, bulk-oriented reflow ovens.

Setup and Operation: Ease of Use Comparison

Soldering stations offer straightforward setup with minimal calibration, making them ideal for quick repairs and prototyping, while reflow ovens require precise temperature profiling and setup to ensure consistent soldering quality. Operation of soldering stations involves manual control, allowing for immediate adjustments, whereas reflow ovens operate on automated cycles, demanding pre-programmed profiles but enabling batch processing. The ease of use for soldering stations favors hands-on tasks, and reflow ovens excel in high-volume, repeatable production environments.

Cost Analysis: Soldering Station vs Reflow Oven

Soldering stations generally have a lower initial cost, typically ranging from $50 to $300, making them suitable for small-scale or prototype work, while reflow ovens can cost from $1,000 to over $10,000 depending on size and features, reflecting their use in larger production environments. Operational costs for soldering stations remain minimal with basic maintenance and consumables, whereas reflow ovens incur higher energy consumption and require periodic calibration and maintenance to ensure consistent thermal profiles. Total cost of ownership for soldering stations favors low-volume, manual tasks, whereas reflow ovens justify their investment through increased throughput and automation in mass production settings.

Suitability for Small-Scale and Large-Scale Production

Soldering stations are highly suitable for small-scale production and prototype development due to their precision and ease of use for manual soldering tasks. Reflow ovens excel in large-scale production by enabling simultaneous soldering of multiple components with consistent temperature profiles, ensuring uniform quality. Selecting the appropriate equipment depends on production volume, with soldering stations offering flexibility for low volumes and reflow ovens enhancing efficiency in high-volume manufacturing.

Maintenance and Longevity of Each Equipment

Soldering stations require regular tip cleaning and replacement to maintain optimal performance, with their maintenance costs generally lower than those of reflow ovens. Reflow ovens demand periodic calibration, conveyor belt upkeep, and thorough cleaning of internal components to ensure consistent temperature profiles, contributing to higher maintenance complexity and expenses. In terms of longevity, soldering stations typically have a lifespan of 5 to 10 years, while well-maintained reflow ovens can operate effectively for 10 to 15 years or more under industrial conditions.

Choosing the Right Tool for Your Soldering Needs

Soldering stations offer precise control for manual, small-scale electronics assembly, making them ideal for detailed repairs and prototype work. Reflow ovens provide consistent, automated heating suitable for mass production and complex surface-mount device (SMD) soldering. Selecting between these depends on production volume, board complexity, and the required temperature uniformity for optimal solder joint quality.

Soldering station vs Reflow oven Infographic

productdif.com

productdif.com