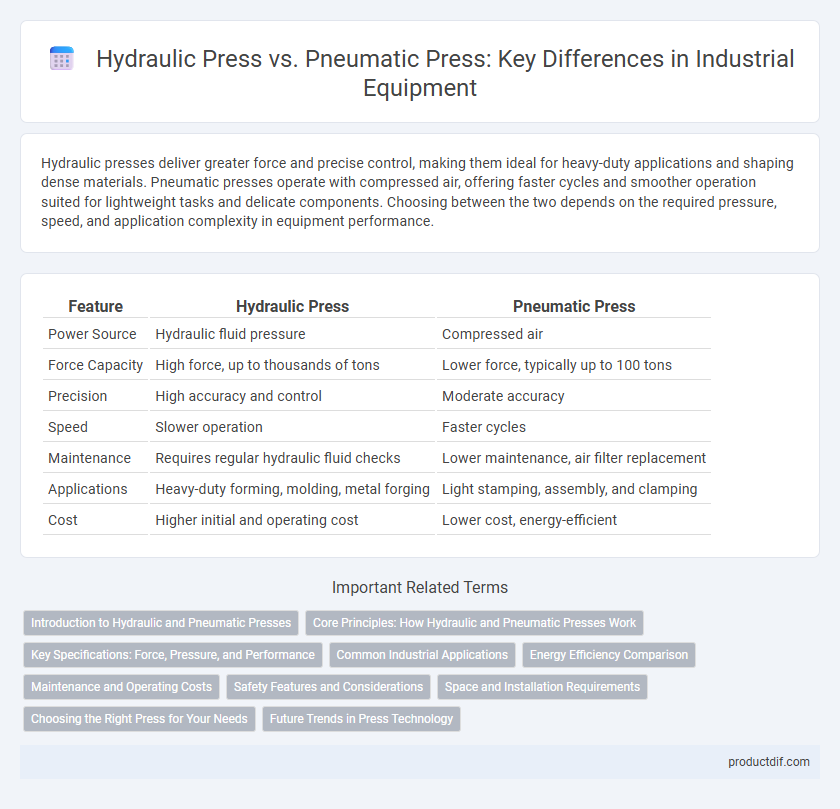

Hydraulic presses deliver greater force and precise control, making them ideal for heavy-duty applications and shaping dense materials. Pneumatic presses operate with compressed air, offering faster cycles and smoother operation suited for lightweight tasks and delicate components. Choosing between the two depends on the required pressure, speed, and application complexity in equipment performance.

Table of Comparison

| Feature | Hydraulic Press | Pneumatic Press |

|---|---|---|

| Power Source | Hydraulic fluid pressure | Compressed air |

| Force Capacity | High force, up to thousands of tons | Lower force, typically up to 100 tons |

| Precision | High accuracy and control | Moderate accuracy |

| Speed | Slower operation | Faster cycles |

| Maintenance | Requires regular hydraulic fluid checks | Lower maintenance, air filter replacement |

| Applications | Heavy-duty forming, molding, metal forging | Light stamping, assembly, and clamping |

| Cost | Higher initial and operating cost | Lower cost, energy-efficient |

Introduction to Hydraulic and Pneumatic Presses

Hydraulic presses utilize incompressible fluid to generate high force through Pascal's principle, making them ideal for heavy-duty applications such as metal forming and molding. Pneumatic presses operate using compressed air, offering faster cycle times and cleaner operation suited for lighter tasks like assembly and pressing of delicate components. Both systems provide precise control, but hydraulic presses excel in high-force, low-speed scenarios while pneumatic presses are preferred for rapid, low-force operations.

Core Principles: How Hydraulic and Pneumatic Presses Work

Hydraulic presses operate by using incompressible fluid to transfer force through a piston, creating powerful and precise pressure ideal for heavy-duty applications. Pneumatic presses rely on compressed air to generate force, offering faster cycles and cleaner operation but with less force compared to hydraulic systems. Understanding these core principles highlights hydraulic presses' suitability for tasks requiring high force and precise control, while pneumatic presses excel in speed and efficiency for lighter assembly processes.

Key Specifications: Force, Pressure, and Performance

Hydraulic presses deliver high force output, typically ranging from 10 to over 10,000 tons, with operating pressures up to 700 bar, making them ideal for heavy-duty forming and molding tasks requiring consistent, powerful performance. Pneumatic presses operate at lower forces, generally up to 10 tons, with pressure levels around 6 to 8 bar, suited for lighter applications where speed and efficiency are prioritized. Performance differences hinge on hydraulic systems offering precise force control and smooth operation, while pneumatic systems excel in rapid cycling and lower maintenance needs.

Common Industrial Applications

Hydraulic presses are widely used in heavy-duty industrial applications such as metal forming, forging, and deep drawing due to their high pressure and precise control capabilities. Pneumatic presses are common in lighter applications like assembly, punching, and molding where faster cycle speeds and lower force are sufficient. Both types of presses optimize industrial productivity by catering to specific force and speed requirements in manufacturing processes.

Energy Efficiency Comparison

Hydraulic presses generally offer higher energy efficiency due to their ability to generate greater force with less power consumption, especially for heavy-duty applications requiring precise control. Pneumatic presses consume more energy as they rely on compressed air, which often results in energy losses during compression and air leaks. Hydraulic systems maintain consistent pressure and minimize energy waste, making them more cost-effective for continuous, high-pressure operations.

Maintenance and Operating Costs

Hydraulic presses typically require more intensive maintenance due to their complex fluid power systems and the need for regular hydraulic fluid checks and replacements, raising operational expenses over time. Pneumatic presses, relying on compressed air, generally incur lower maintenance costs with simpler components and fewer risks of fluid leaks, making them cost-effective for continuous use. Evaluating total cost of ownership is crucial, as hydraulic systems offer higher force capabilities but at increased maintenance and energy costs compared to pneumatic alternatives.

Safety Features and Considerations

Hydraulic presses offer superior safety features such as pressure relief valves and overload protection to prevent accidents caused by excessive force. Pneumatic presses reduce the risk of sudden pressure spikes by utilizing compressed air, allowing for smoother operation and safer pressure control. Both systems require regular maintenance and safety checks to ensure optimal functioning and to minimize risks related to mechanical failure or operator error.

Space and Installation Requirements

Hydraulic presses require more space due to their larger reservoirs, pumps, and extensive piping compared to pneumatic presses, which have a compact design and simpler installation. Pneumatic presses need a compressed air source and minimal mounting area, making them ideal for facilities with limited space. Hydraulic systems demand robust foundation and floor support for installation, whereas pneumatic presses can often be mounted on existing workbenches or smaller platforms.

Choosing the Right Press for Your Needs

Hydraulic presses provide high force and precise control, making them ideal for heavy-duty applications such as metal forming and deep drawing. Pneumatic presses operate with compressed air and are better suited for lighter tasks requiring faster cycle times and lower force, such as assembly and packaging. Selecting the right press depends on application requirements, force capacity, speed, and material type to ensure optimal performance and cost-efficiency.

Future Trends in Press Technology

Emerging trends in press technology emphasize automation and energy efficiency, with hydraulic presses advancing through smart sensors and variable speed drives for precise control and reduced power consumption. Pneumatic presses integrate IoT-enabled monitoring systems to enhance real-time diagnostics and predictive maintenance, improving operational uptime. Both technologies are increasingly incorporating eco-friendly materials and designs to meet stringent environmental regulations and support sustainable manufacturing practices.

Hydraulic press vs Pneumatic press Infographic

productdif.com

productdif.com