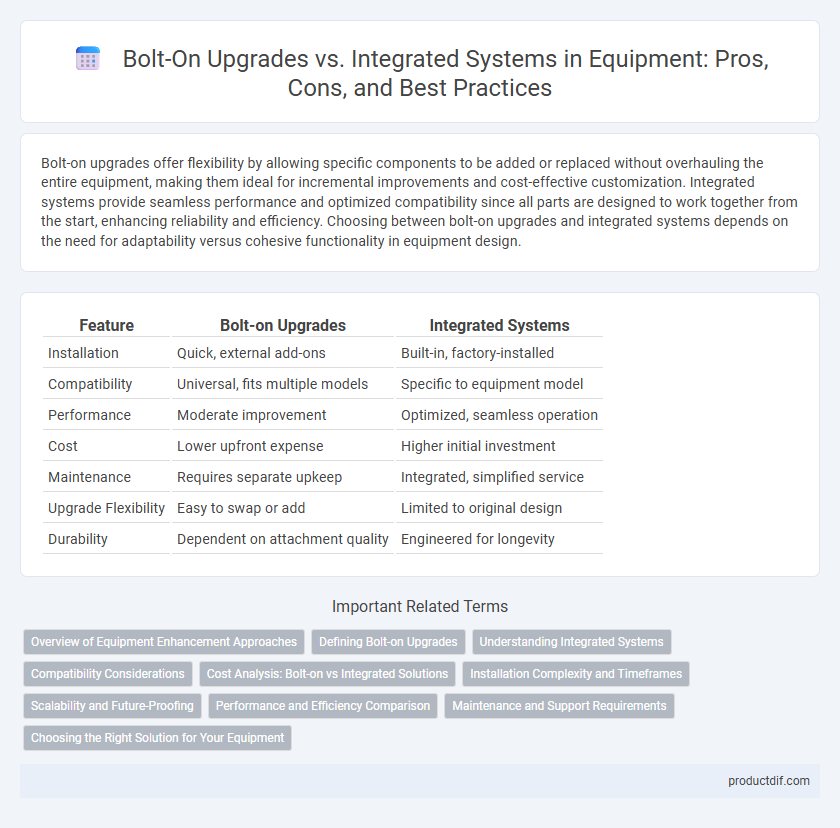

Bolt-on upgrades offer flexibility by allowing specific components to be added or replaced without overhauling the entire equipment, making them ideal for incremental improvements and cost-effective customization. Integrated systems provide seamless performance and optimized compatibility since all parts are designed to work together from the start, enhancing reliability and efficiency. Choosing between bolt-on upgrades and integrated systems depends on the need for adaptability versus cohesive functionality in equipment design.

Table of Comparison

| Feature | Bolt-on Upgrades | Integrated Systems |

|---|---|---|

| Installation | Quick, external add-ons | Built-in, factory-installed |

| Compatibility | Universal, fits multiple models | Specific to equipment model |

| Performance | Moderate improvement | Optimized, seamless operation |

| Cost | Lower upfront expense | Higher initial investment |

| Maintenance | Requires separate upkeep | Integrated, simplified service |

| Upgrade Flexibility | Easy to swap or add | Limited to original design |

| Durability | Dependent on attachment quality | Engineered for longevity |

Overview of Equipment Enhancement Approaches

Bolt-on upgrades offer modular enhancement options for existing equipment, enabling quick installation and cost-effective customization without replacing entire systems. Integrated systems provide seamless performance improvements by redesigning equipment architecture for optimized functionality and durability. Choosing between these approaches depends on compatibility, budget constraints, and long-term maintenance considerations.

Defining Bolt-on Upgrades

Bolt-on upgrades refer to modular equipment enhancements designed for easy installation onto existing machinery without requiring extensive system overhaul. These upgrades offer flexibility by allowing targeted improvements such as adding sensors, controllers, or attachments that enhance performance or functionality. Unlike integrated systems, bolt-on upgrades minimize downtime and reduce costs by preserving the base equipment structure while enabling scalability.

Understanding Integrated Systems

Integrated systems in equipment combine multiple components into a single, cohesive unit designed for seamless operation and enhanced performance. These systems optimize compatibility, reduce installation complexity, and improve reliability by eliminating the need for separate interfacing between components. Understanding integrated systems highlights their advantages in maintenance efficiency, cost-effectiveness, and overall system durability compared to bolt-on upgrades.

Compatibility Considerations

Bolt-on upgrades offer flexible compatibility with existing equipment, allowing selective enhancement without full system replacement. Integrated systems provide seamless cohesion but may require comprehensive compatibility checks across hardware and software components. Evaluating interface standards and protocol support is essential to ensure smooth operation and avoid performance bottlenecks.

Cost Analysis: Bolt-on vs Integrated Solutions

Bolt-on upgrades typically offer lower initial costs and faster implementation compared to integrated systems, making them attractive for budget-conscious projects. However, integrated solutions often provide greater long-term value through streamlined maintenance, improved system compatibility, and reduced downtime. Detailed cost analysis should factor in total cost of ownership, including installation, training, scalability, and potential efficiency gains.

Installation Complexity and Timeframes

Bolt-on upgrades offer simpler installation processes with minimal downtime, allowing equipment to be enhanced without significant disassembly or reconfiguration. Integrated systems require comprehensive planning, specialized tools, and skilled technicians, resulting in longer installation timeframes and higher complexity. Selecting bolt-on upgrades can reduce operational interruptions, while integrated systems provide seamless performance but demand extensive installation efforts.

Scalability and Future-Proofing

Bolt-on upgrades offer flexibility by allowing companies to scale equipment capacity incrementally without overhauling entire systems, making them ideal for adapting to changing operational demands. Integrated systems provide cohesive performance and streamlined interoperability but may pose challenges for future-proofing due to limited modularity and higher upgrade costs. Prioritizing bolt-on solutions enhances scalability and ensures long-term adaptability by facilitating easier technology refreshes and incremental improvements.

Performance and Efficiency Comparison

Bolt-on upgrades provide targeted performance enhancements by allowing specific components to be optimized without replacing the entire system, resulting in cost-effective improvements and quicker installation times. Integrated systems are designed for overall efficiency, ensuring seamless communication between components that maximizes energy use and reduces downtime through synchronized operation. Performance gains from bolt-on solutions may vary due to compatibility issues, while integrated systems deliver consistent efficiency improvements through holistic design.

Maintenance and Support Requirements

Bolt-on upgrades often simplify maintenance by isolating new components, allowing targeted repairs without affecting the entire system, which reduces downtime and support costs. Integrated systems require comprehensive maintenance strategies as the interconnected components cause failures to propagate, increasing diagnostic complexity and support demands. Choosing between bolt-on and integrated upgrades impacts long-term equipment reliability and the scope of technical support needed.

Choosing the Right Solution for Your Equipment

Bolt-on upgrades offer flexibility and cost-effectiveness by enhancing existing equipment without extensive modifications, ideal for incremental performance improvements. Integrated systems deliver seamless operation and higher efficiency through purpose-built designs tailored to specific equipment needs. Evaluating equipment age, intended use, and budget constraints is crucial when selecting between bolt-on upgrades and fully integrated solutions for optimal long-term value.

Bolt-on upgrades vs integrated systems Infographic

productdif.com

productdif.com