Pick and place robotics offer precise and flexible handling of individual items, improving efficiency in complex assembly or packaging processes. Conveyor systems excel at continuous movement of bulk materials or products, ensuring smooth and consistent flow through production lines. Choosing between these technologies depends on the specific task requirements, with robotics optimizing accuracy and conveyors maximizing throughput.

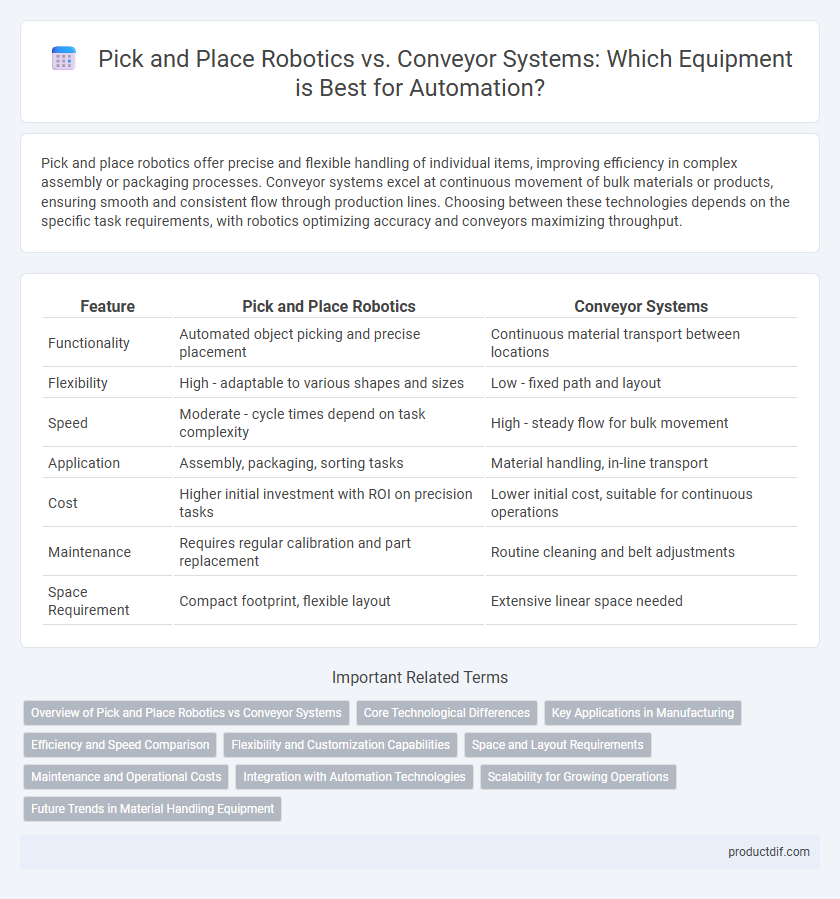

Table of Comparison

| Feature | Pick and Place Robotics | Conveyor Systems |

|---|---|---|

| Functionality | Automated object picking and precise placement | Continuous material transport between locations |

| Flexibility | High - adaptable to various shapes and sizes | Low - fixed path and layout |

| Speed | Moderate - cycle times depend on task complexity | High - steady flow for bulk movement |

| Application | Assembly, packaging, sorting tasks | Material handling, in-line transport |

| Cost | Higher initial investment with ROI on precision tasks | Lower initial cost, suitable for continuous operations |

| Maintenance | Requires regular calibration and part replacement | Routine cleaning and belt adjustments |

| Space Requirement | Compact footprint, flexible layout | Extensive linear space needed |

Overview of Pick and Place Robotics vs Conveyor Systems

Pick and place robotics offer high precision and flexibility for handling diverse products, enabling complex assembly and packaging tasks with rapid cycle times. Conveyor systems excel in continuous, automated material transport, improving workflow efficiency and reducing manual labor in repetitive movement across production lines. Combining pick and place robotics with conveyor technology optimizes manufacturing automation by synchronizing precise object positioning with seamless product flow.

Core Technological Differences

Pick and place robotics utilize advanced vision systems and multi-axis articulated arms for precise, flexible handling of diverse items, while conveyor systems rely on continuous mechanical movement to transport products efficiently along fixed paths. Robotics offer programmable adaptability and complex manipulation capabilities, enabling tasks such as sorting, packaging, and assembly with high accuracy. Conveyor systems excel in high-volume linear material flow but lack the dexterity and intelligence inherent in robotic pick and place mechanisms.

Key Applications in Manufacturing

Pick and place robotics excel in high-precision assembly tasks, electronic component placement, and packaging operations where speed and accuracy are critical. Conveyor systems are widely used for continuous, high-volume transport of materials, reducing manual handling and improving workflow efficiency in automotive, food processing, and pharmaceutical manufacturing. Combining both technologies optimizes production lines by integrating precise automation with efficient material movement.

Efficiency and Speed Comparison

Pick and place robotics offer superior precision and can handle complex tasks with faster cycle times, significantly boosting operational efficiency. Conveyor systems excel at continuous material movement and can manage high volumes with consistent speed but lack the adaptability of robotics. Integrating pick and place robots with conveyor systems often results in optimal throughput by combining speed with flexibility in automation processes.

Flexibility and Customization Capabilities

Pick and place robotics offer superior flexibility and customization capabilities compared to conveyor systems, adapting easily to various product sizes and shapes through programmable software. These robots enable precise handling and rapid reconfiguration for different tasks, enhancing operational efficiency in dynamic production environments. Conveyor systems, while reliable for continuous transport, lack the adaptable control and intricate manipulation that robotics provide.

Space and Layout Requirements

Pick and place robotics require minimal floor space due to their compact design and flexible installation options, making them ideal for environments with limited layout availability. Conveyor systems demand extensive linear space for effective material transport, often necessitating significant modifications to factory floor plans. Optimizing space utilization involves evaluating workflow patterns, where robotic arms enable vertical stacking and multi-axis movement, contrasting with the fixed, horizontal footprint of conveyor belts.

Maintenance and Operational Costs

Pick and place robotics typically incur higher upfront maintenance costs due to their complex mechanical and electronic components, yet they offer lower operational costs through precision and reduced labor requirements. Conveyor systems demand regular upkeep for belts, motors, and rollers, leading to moderate maintenance expenses, but operational costs can increase with labor-intensive monitoring and slower adaptability. Selecting between these systems hinges on balancing the trade-off between initial maintenance investment and ongoing operational efficiency.

Integration with Automation Technologies

Pick and place robotics seamlessly integrate with advanced automation technologies such as AI-driven vision systems and flexible grippers, enabling precise component handling and rapid adaptation to production variations. Conveyor systems complement automation by providing continuous material flow and synchronization with robotic arms through IoT-enabled sensors and programmable logic controllers (PLCs). Combining pick and place robots with conveyor networks enhances overall manufacturing efficiency by facilitating real-time data exchange and coordinated motion control.

Scalability for Growing Operations

Pick and place robotics offer exceptional scalability for growing operations by easily integrating with existing workflows and adapting to increased production volumes through programmable flexibility. Conveyor systems provide scalable solutions by enabling modular expansion and customized layouts to accommodate higher throughput and diverse product lines. Selecting between these technologies depends on the specific operational complexity and growth trajectory, with robotics excelling in precision tasks and conveyors enhancing continuous material handling.

Future Trends in Material Handling Equipment

Pick and place robotics are advancing with enhanced AI integration and flexible gripper technologies, enabling precise, adaptable handling of diverse materials, while conveyor systems are evolving through smart automation and IoT connectivity for real-time monitoring and efficiency optimization. The convergence of robotics and conveyor systems is driving the development of hybrid material handling solutions that maximize throughput and reduce operational costs. Future trends emphasize sustainability, with energy-efficient designs and predictive maintenance becoming standard in modern equipment.

Pick and place robotics vs Conveyor systems Infographic

productdif.com

productdif.com