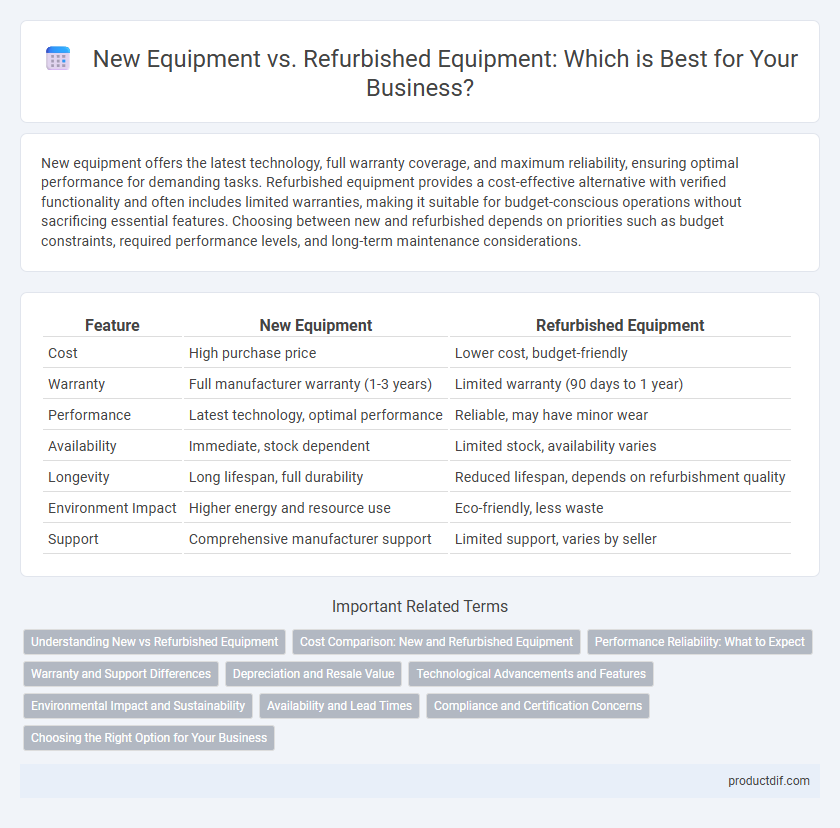

New equipment offers the latest technology, full warranty coverage, and maximum reliability, ensuring optimal performance for demanding tasks. Refurbished equipment provides a cost-effective alternative with verified functionality and often includes limited warranties, making it suitable for budget-conscious operations without sacrificing essential features. Choosing between new and refurbished depends on priorities such as budget constraints, required performance levels, and long-term maintenance considerations.

Table of Comparison

| Feature | New Equipment | Refurbished Equipment |

|---|---|---|

| Cost | High purchase price | Lower cost, budget-friendly |

| Warranty | Full manufacturer warranty (1-3 years) | Limited warranty (90 days to 1 year) |

| Performance | Latest technology, optimal performance | Reliable, may have minor wear |

| Availability | Immediate, stock dependent | Limited stock, availability varies |

| Longevity | Long lifespan, full durability | Reduced lifespan, depends on refurbishment quality |

| Environment Impact | Higher energy and resource use | Eco-friendly, less waste |

| Support | Comprehensive manufacturer support | Limited support, varies by seller |

Understanding New vs Refurbished Equipment

New equipment offers the latest technology, full warranties, and peak performance, ensuring reliability and longevity for critical operations. Refurbished equipment undergoes thorough inspection and repairs to meet manufacturer standards, providing a cost-effective alternative with reduced depreciation. Evaluating the balance between initial investment and long-term value is essential for making informed equipment procurement decisions.

Cost Comparison: New and Refurbished Equipment

New equipment typically involves higher upfront costs due to the latest technology, full warranties, and guaranteed performance, while refurbished equipment offers significant savings by using pre-owned or returned items that have been restored to good working condition. Refurbished equipment costs can be 30% to 50% less than new models, making it an attractive option for budget-conscious businesses without compromising essential functionality. Maintenance and replacement parts for refurbished gear may incur additional expenses, but the initial cost advantage often outweighs these factors in cost-sensitive applications.

Performance Reliability: What to Expect

New equipment typically offers superior performance reliability due to advanced technology and full manufacturer's warranties, ensuring optimal operation and minimal downtime. Refurbished equipment can provide cost-effective solutions with acceptable reliability if sourced from reputable vendors who thoroughly test and certify the products. Users should expect slightly higher maintenance requirements and potential variability in refurbished equipment's lifespan compared to brand-new units.

Warranty and Support Differences

New equipment typically offers a comprehensive manufacturer's warranty covering defects and performance issues for an extended period, often ranging from one to five years, ensuring robust post-purchase support. Refurbished equipment warranties are generally shorter, ranging from 90 days to one year, and may provide limited coverage that excludes certain parts or types of damage. Support for new equipment often includes direct access to manufacturer customer service, while refurbished units may rely on third-party vendors or limited service options.

Depreciation and Resale Value

New equipment typically experiences rapid depreciation within the first few years, significantly impacting its resale value. Refurbished equipment, having already undergone initial depreciation, tends to retain a higher percentage of its value over time, offering better cost efficiency. Choosing refurbished equipment can optimize asset management by balancing lower acquisition costs with stable resale potential.

Technological Advancements and Features

New equipment typically integrates the latest technological advancements, offering enhanced features such as improved energy efficiency, advanced automation, and cutting-edge safety systems. Refurbished equipment may lack these innovations, as it is based on older models that might not support recent software updates or modern connectivity options. Investing in new equipment ensures access to state-of-the-art technology, optimizing operational performance and long-term reliability.

Environmental Impact and Sustainability

New equipment often requires higher resource consumption and energy during manufacturing, leading to increased carbon emissions compared to refurbished equipment. Refurbished equipment extends product life cycles, reducing electronic waste and conserving raw materials, which significantly lowers environmental impact. Choosing refurbished options supports sustainable practices by minimizing landfill contributions and promoting circular economy principles.

Availability and Lead Times

New equipment typically offers faster availability with shorter lead times due to production schedules aligned with demand forecasting. Refurbished equipment often experiences variable lead times depending on inspection, repair, and testing processes, which can delay delivery. Businesses seeking immediate deployment usually prefer new equipment, while those prioritizing cost savings may accept longer waiting periods for refurbished options.

Compliance and Certification Concerns

New equipment typically comes with up-to-date compliance certifications and warranties that ensure adherence to the latest industry standards and regulations. Refurbished equipment may pose compliance risks if certification is outdated or missing, requiring thorough inspection and potential re-certification to meet regulatory requirements. Maintaining proper documentation and verifying third-party certification is crucial for both types to guarantee safe and lawful operation.

Choosing the Right Option for Your Business

Selecting new equipment ensures the latest technology, warranty coverage, and reliable performance, which can enhance operational efficiency and reduce downtime. Refurbished equipment offers cost-effective solutions with substantial savings, often certified and tested to meet industry standards, making it ideal for businesses with budget constraints. Evaluating factors such as total cost of ownership, equipment lifespan, and specific business needs helps determine the most strategic investment between new and refurbished options.

New equipment vs refurbished equipment Infographic

productdif.com

productdif.com