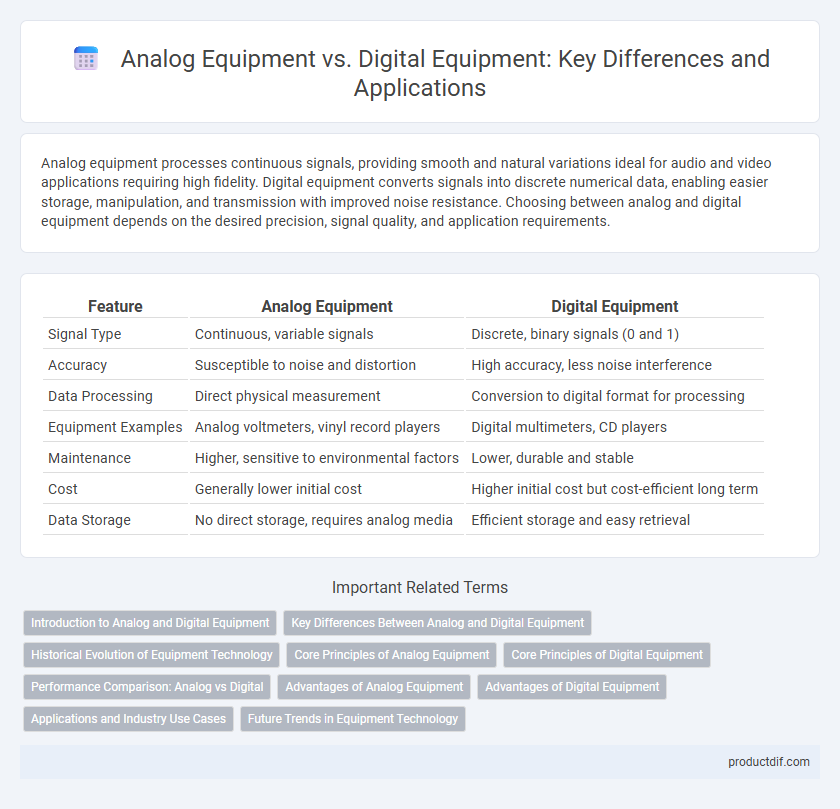

Analog equipment processes continuous signals, providing smooth and natural variations ideal for audio and video applications requiring high fidelity. Digital equipment converts signals into discrete numerical data, enabling easier storage, manipulation, and transmission with improved noise resistance. Choosing between analog and digital equipment depends on the desired precision, signal quality, and application requirements.

Table of Comparison

| Feature | Analog Equipment | Digital Equipment |

|---|---|---|

| Signal Type | Continuous, variable signals | Discrete, binary signals (0 and 1) |

| Accuracy | Susceptible to noise and distortion | High accuracy, less noise interference |

| Data Processing | Direct physical measurement | Conversion to digital format for processing |

| Equipment Examples | Analog voltmeters, vinyl record players | Digital multimeters, CD players |

| Maintenance | Higher, sensitive to environmental factors | Lower, durable and stable |

| Cost | Generally lower initial cost | Higher initial cost but cost-efficient long term |

| Data Storage | No direct storage, requires analog media | Efficient storage and easy retrieval |

Introduction to Analog and Digital Equipment

Analog equipment processes continuous signals that vary smoothly over time, capturing real-world phenomena like sound and light with infinite resolution within physical limits. Digital equipment converts analog signals into discrete numerical values, allowing for precise manipulation, storage, and reproduction through binary code. The fundamental difference lies in analog devices representing data in waveforms, while digital devices use sequences of zeros and ones for enhanced accuracy and noise resistance.

Key Differences Between Analog and Digital Equipment

Analog equipment processes continuous signals, capturing real-world variations with smooth, natural representations ideal for audio and video fidelity. Digital equipment converts signals into discrete binary data, enabling precise manipulation, storage, and error correction, improving reliability and versatility in communication systems. Key differences include signal type, noise susceptibility, and data processing methods, where analog excels in nuanced input capture and digital leads in efficiency and scalability.

Historical Evolution of Equipment Technology

Analog equipment originated in the early 19th century, relying on continuous signal variations to represent information, which was pivotal in industries like telecommunications and audio recording. Digital equipment emerged prominently in the late 20th century, utilizing discrete binary data for enhanced precision, storage, and processing capabilities that revolutionized computing, electronics, and communication systems. The transition from analog to digital technology marked a significant evolution, driven by advancements in microprocessors, integrated circuits, and software development, enabling faster, more reliable, and scalable equipment solutions.

Core Principles of Analog Equipment

Analog equipment fundamentally operates by processing continuous signals that vary in amplitude, frequency, or phase to represent information. Its core principles rely on the direct manipulation of physical quantities such as voltage, current, or mechanical movement, which enables precise real-time measurement and transmission. This contrasts with digital equipment, which encodes information in discrete numerical values, emphasizing the inherent sensitivity and fidelity of analog systems to subtle changes in signal characteristics.

Core Principles of Digital Equipment

Digital equipment operates on the core principles of binary data processing, utilizing discrete signals represented by 0s and 1s to ensure high accuracy and noise resistance. Unlike analog equipment, which relies on continuous signal variations, digital systems convert analog inputs into digital signals through analog-to-digital converters, enabling precise data manipulation and storage. This fundamental shift allows digital equipment to offer enhanced reliability, scalability, and integration with modern computing technologies.

Performance Comparison: Analog vs Digital

Analog equipment processes continuous signals, offering superior real-time response and smoother signal variations, which enhances audio and video fidelity in certain applications. Digital equipment converts signals into discrete binary data, enabling error correction, noise reduction, and easier integration with computer systems, leading to higher precision and consistency in performance. While analog excels in capturing natural signal nuances, digital provides enhanced functionality and scalability for complex processing tasks.

Advantages of Analog Equipment

Analog equipment offers superior real-time signal processing with minimal latency, crucial for audio and video applications requiring immediate response. Its continuous signal representation ensures more natural and accurate reproduction of sound and images compared to the discrete sampling used in digital systems. Moreover, analog devices often provide simpler designs with lower cost and power consumption, making them ideal for specific industrial and scientific instrumentation tasks.

Advantages of Digital Equipment

Digital equipment offers superior accuracy and precision compared to analog equipment, enabling enhanced measurement reliability in various applications. It provides easier data storage, processing, and integration with modern computerized systems, resulting in improved efficiency and automation. Digital devices also feature better noise resistance and calibration stability, minimizing errors and maintenance needs over time.

Applications and Industry Use Cases

Analog equipment excels in audio processing, instrumentation, and telecommunications due to its continuous signal representation, making it ideal for applications requiring high-fidelity sound and real-time analog measurements. Digital equipment is predominant in computing, data storage, and modern communication systems, leveraging discrete signal processing for enhanced accuracy, programmability, and integration in industries like IT, healthcare, and automotive. Hybrid systems combining analog and digital components are increasingly used in signal conversion and control systems to optimize performance across diverse industrial applications.

Future Trends in Equipment Technology

Future trends in equipment technology emphasize the integration of digital equipment due to its enhanced precision, real-time data processing capabilities, and remote monitoring features. Analog equipment continues to serve niche applications requiring simplicity and robustness, but digital systems dominate advancements through AI-driven diagnostics, IoT connectivity, and cloud-based analytics. Increasing adoption of hybrid models combining analog reliability with digital adaptability is shaping the evolution of equipment in industries such as manufacturing, healthcare, and telecommunications.

Analog Equipment vs Digital Equipment Infographic

productdif.com

productdif.com