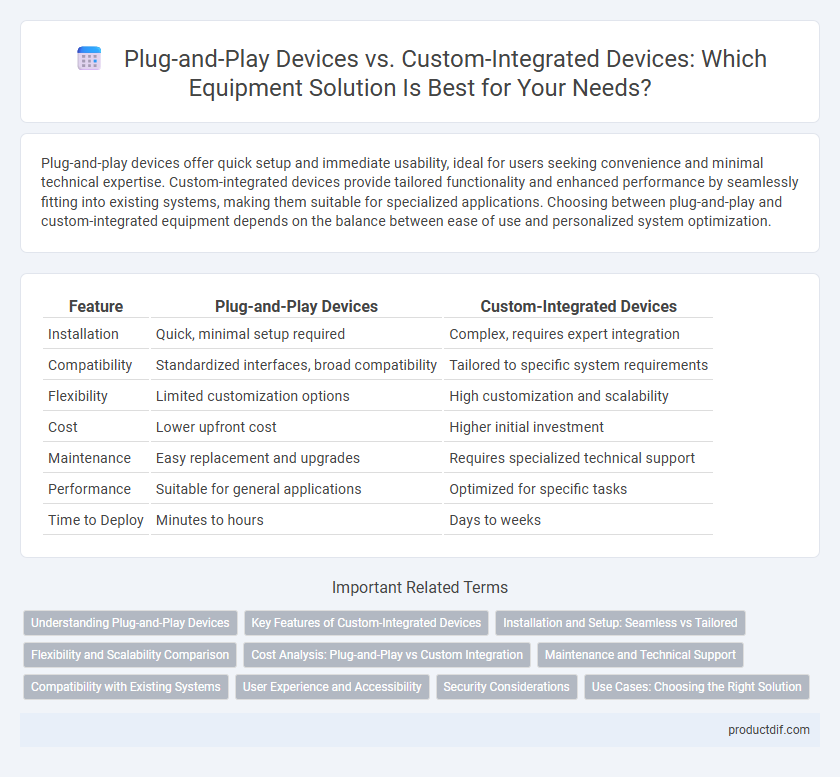

Plug-and-play devices offer quick setup and immediate usability, ideal for users seeking convenience and minimal technical expertise. Custom-integrated devices provide tailored functionality and enhanced performance by seamlessly fitting into existing systems, making them suitable for specialized applications. Choosing between plug-and-play and custom-integrated equipment depends on the balance between ease of use and personalized system optimization.

Table of Comparison

| Feature | Plug-and-Play Devices | Custom-Integrated Devices |

|---|---|---|

| Installation | Quick, minimal setup required | Complex, requires expert integration |

| Compatibility | Standardized interfaces, broad compatibility | Tailored to specific system requirements |

| Flexibility | Limited customization options | High customization and scalability |

| Cost | Lower upfront cost | Higher initial investment |

| Maintenance | Easy replacement and upgrades | Requires specialized technical support |

| Performance | Suitable for general applications | Optimized for specific tasks |

| Time to Deploy | Minutes to hours | Days to weeks |

Understanding Plug-and-Play Devices

Plug-and-play devices offer seamless connectivity without requiring complex installation or configuration, enabling immediate use across various equipment systems. These devices are built with standardized interfaces and drivers that automatically recognize hardware, reducing downtime and streamlining operational efficiency. Understanding the compatibility and ease of integration inherent in plug-and-play technology is crucial for optimizing equipment performance and minimizing technical support needs.

Key Features of Custom-Integrated Devices

Custom-integrated devices offer tailored configurations that align precisely with specific operational requirements, ensuring seamless interoperability with existing systems. These devices support advanced customization options such as unique firmware, proprietary protocols, and optimized hardware components for enhanced performance. Their design enables robust scalability and adaptability, making them ideal for complex industrial applications demanding high reliability and precision.

Installation and Setup: Seamless vs Tailored

Plug-and-play devices offer seamless installation with minimal configuration, enabling users to quickly connect and operate equipment without specialized technical knowledge. Custom-integrated devices require tailored setup procedures often involving specialized software and professional installation to ensure compatibility with existing systems. The choice between these options impacts the time and complexity of deployment, with plug-and-play favoring speed and accessibility, while custom integration prioritizes precise system harmonization.

Flexibility and Scalability Comparison

Plug-and-play devices offer high flexibility and quick deployment, enabling users to easily add or replace components without extensive technical knowledge. Custom-integrated devices provide superior scalability, as they are designed specifically to meet unique operational requirements and can be expanded or modified to optimize performance over time. Choosing between plug-and-play and custom-integrated solutions depends on the need for immediate adaptability versus long-term tailored growth.

Cost Analysis: Plug-and-Play vs Custom Integration

Plug-and-play devices typically offer lower upfront costs due to standardized manufacturing and reduced installation time, making them cost-effective for quick deployment. Custom-integrated devices often involve higher initial expenses driven by tailored engineering, specialized components, and extended development cycles that increase labor and testing fees. Analyzing total cost of ownership reveals plug-and-play options minimize initial capital expenditure, while custom integration may provide long-term savings through optimized performance and reduced maintenance costs.

Maintenance and Technical Support

Plug-and-play devices offer simplified maintenance with standardized components and widely available technical support, reducing downtime and service costs. Custom-integrated devices require specialized knowledge for troubleshooting and maintenance, often involving manufacturer-specific support and longer resolution times. Choosing plug-and-play equipment streamlines repairs and ensures quicker access to expertise compared to custom-integrated systems.

Compatibility with Existing Systems

Plug-and-play devices offer seamless compatibility with existing systems allowing quick installation and immediate functionality without complex configurations. Custom-integrated devices require tailored adjustments to align precisely with the system architecture, ensuring optimized performance but demanding more time and technical expertise. Compatibility with legacy infrastructure is crucial to minimize downtime and maximize operational efficiency in both approaches.

User Experience and Accessibility

Plug-and-play devices offer immediate usability with minimal setup, enhancing user experience through straightforward installation and broad compatibility. Custom-integrated devices provide tailored functionality and seamless system integration, improving accessibility for specialized applications but often requiring professional configuration. Selecting between these options depends on the need for convenience versus personalized performance and accessibility in complex environments.

Security Considerations

Plug-and-play devices offer ease of installation but often lack robust security protocols, increasing vulnerability to unauthorized access and malware attacks. Custom-integrated devices provide tailored security measures such as encrypted communication and access controls, reducing risk by fitting specific organizational requirements. Regular firmware updates and compatibility with existing security infrastructure are essential to maintain the integrity of both device types.

Use Cases: Choosing the Right Solution

Plug-and-play devices excel in scenarios requiring rapid deployment and minimal technical expertise, such as small office setups and temporary installations, providing immediate functionality without complex configuration. Custom-integrated devices suit large-scale enterprises and specialized applications where tailored performance, scalability, and seamless integration into existing systems are critical for optimized operations. Assessing factors like deployment time, technical resources, and long-term system requirements ensures selection of the solution that aligns precisely with operational goals.

Plug-and-play devices vs Custom-integrated devices Infographic

productdif.com

productdif.com