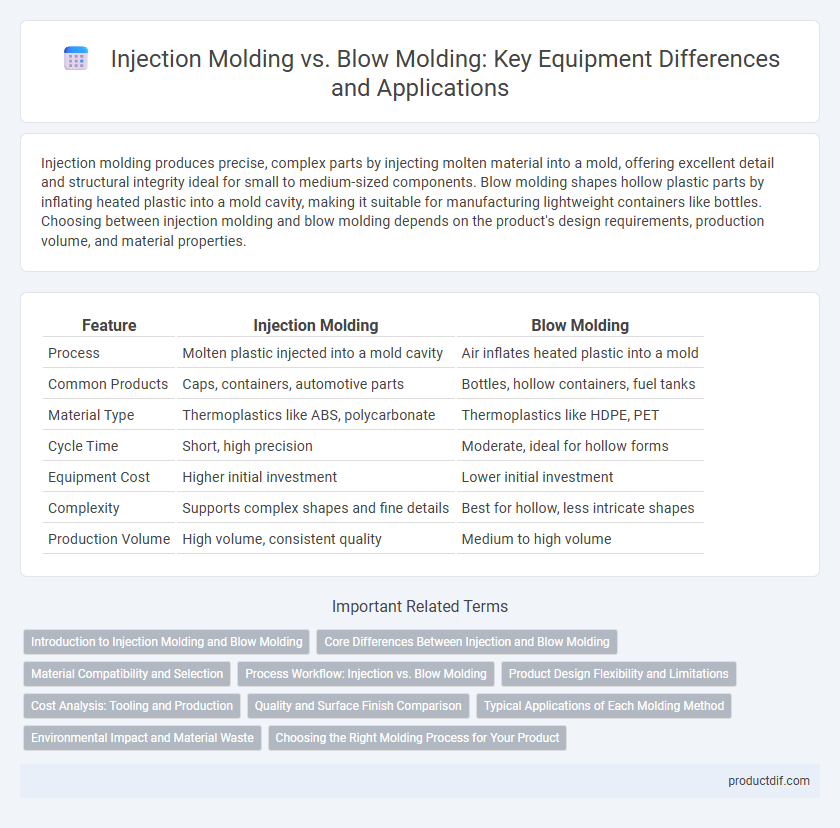

Injection molding produces precise, complex parts by injecting molten material into a mold, offering excellent detail and structural integrity ideal for small to medium-sized components. Blow molding shapes hollow plastic parts by inflating heated plastic into a mold cavity, making it suitable for manufacturing lightweight containers like bottles. Choosing between injection molding and blow molding depends on the product's design requirements, production volume, and material properties.

Table of Comparison

| Feature | Injection Molding | Blow Molding |

|---|---|---|

| Process | Molten plastic injected into a mold cavity | Air inflates heated plastic into a mold |

| Common Products | Caps, containers, automotive parts | Bottles, hollow containers, fuel tanks |

| Material Type | Thermoplastics like ABS, polycarbonate | Thermoplastics like HDPE, PET |

| Cycle Time | Short, high precision | Moderate, ideal for hollow forms |

| Equipment Cost | Higher initial investment | Lower initial investment |

| Complexity | Supports complex shapes and fine details | Best for hollow, less intricate shapes |

| Production Volume | High volume, consistent quality | Medium to high volume |

Introduction to Injection Molding and Blow Molding

Injection molding involves injecting molten material, typically thermoplastic or thermosetting polymers, into a mold cavity to create precise, complex shapes with high dimensional accuracy. Blow molding, primarily used for hollow objects like bottles, forms a parison or preform which is then inflated inside a mold using compressed air to achieve the desired shape. Both techniques utilize specialized equipment such as injection molding machines and blow molding machines, optimized for volume production and material efficiency in packaging and manufacturing industries.

Core Differences Between Injection and Blow Molding

Injection molding involves injecting molten material into a mold cavity to create solid, detailed parts with high precision and complex geometries, ideal for producing items like plastic components and housings. Blow molding, by contrast, uses air pressure to inflate melted plastic inside a mold, forming hollow parts such as bottles and containers with uniform wall thickness. The core differences lie in the manufacturing process: injection molding is best suited for solid, intricate shapes, whereas blow molding excels at creating hollow, lightweight products efficiently.

Material Compatibility and Selection

Injection molding offers superior material compatibility with a wide range of thermoplastics, including ABS, polycarbonate, and nylon, enabling precise control over part complexity and mechanical properties. Blow molding typically utilizes polyethylene and polypropylene due to their excellent melt strength and flexibility, making it ideal for hollow parts like bottles and containers. Selecting the appropriate molding technique hinges on understanding the resin's thermal properties and end-use requirements to ensure optimal performance and cost efficiency.

Process Workflow: Injection vs. Blow Molding

Injection molding involves melting plastic pellets and injecting the molten material into a mold cavity under high pressure, allowing precise control over part shape and thickness. Blow molding starts with creating a hollow parison, which is then inflated inside a mold to form hollow objects like bottles or containers. The injection process suits complex, solid parts with detailed features, while blow molding excels in producing lightweight, hollow products efficiently.

Product Design Flexibility and Limitations

Injection molding offers superior product design flexibility, enabling intricate and detailed shapes with tight tolerances and multi-material options. Blow molding is primarily suited for hollow, lightweight containers with less complex geometries but excels in producing uniform wall thickness and large volumes efficiently. Limitations of injection molding include higher tooling costs and slower production for large hollow parts, while blow molding restricts detailed design features and surface textures.

Cost Analysis: Tooling and Production

Injection molding typically requires higher initial tooling costs due to the complexity of molds, but offers lower per-unit production expenses for large volumes. Blow molding has lower upfront tooling expenses and is more cost-effective for producing hollow plastic parts in medium to small production runs. Evaluating the break-even point between injection and blow molding depends on part design complexity, production volume, and material requirements.

Quality and Surface Finish Comparison

Injection molding produces parts with higher dimensional accuracy and smoother surface finishes compared to blow molding, making it ideal for applications requiring precise tolerances. Blow molding often results in less detailed surface textures and minor inconsistencies due to material stretching during the process. The superior quality and surface finish of injection molding make it best suited for producing complex, high-precision components.

Typical Applications of Each Molding Method

Injection molding excels in producing high-precision, intricate components such as automotive parts, medical devices, and consumer electronics housings due to its ability to create detailed features and complex geometries. Blow molding is typically used for manufacturing hollow plastic products like bottles, containers, and fuel tanks, where uniform wall thickness and lightweight design are crucial. Each molding method aligns with specific production needs, with injection molding favoring detail and rigidity, while blow molding prioritizes hollow, lightweight structures.

Environmental Impact and Material Waste

Injection molding generates less material waste due to its precision in molding complex parts with minimal excess, whereas blow molding often produces more scrap from trimming excess plastic around hollow shapes. The energy consumption in injection molding tends to be higher per cycle but results in lower overall emissions because of reduced reprocessing needs. Blow molding typically uses recycled plastics more effectively, enhancing sustainability despite higher initial waste levels.

Choosing the Right Molding Process for Your Product

Injection molding offers precise, complex shapes and high-strength parts, ideal for detailed components with tight tolerances, while blow molding excels at producing hollow, lightweight containers like bottles and tanks. Selecting the right molding process depends on the product's design requirements, production volume, and material type, with injection molding favored for intricate designs and blow molding for large, hollow parts. Cost-effectiveness, cycle time, and desired product durability also influence the molding choice, ensuring optimal performance and manufacturing efficiency.

Injection molding vs blow molding Infographic

productdif.com

productdif.com