Active redundancy involves multiple components operating simultaneously to ensure continuous system functionality, enhancing reliability by allowing seamless failover without disruption. Passive redundancy relies on standby components that activate only when primary units fail, leading to potential delays in system recovery. Choosing between active and passive redundancy depends on the criticality of uptime, cost considerations, and system complexity.

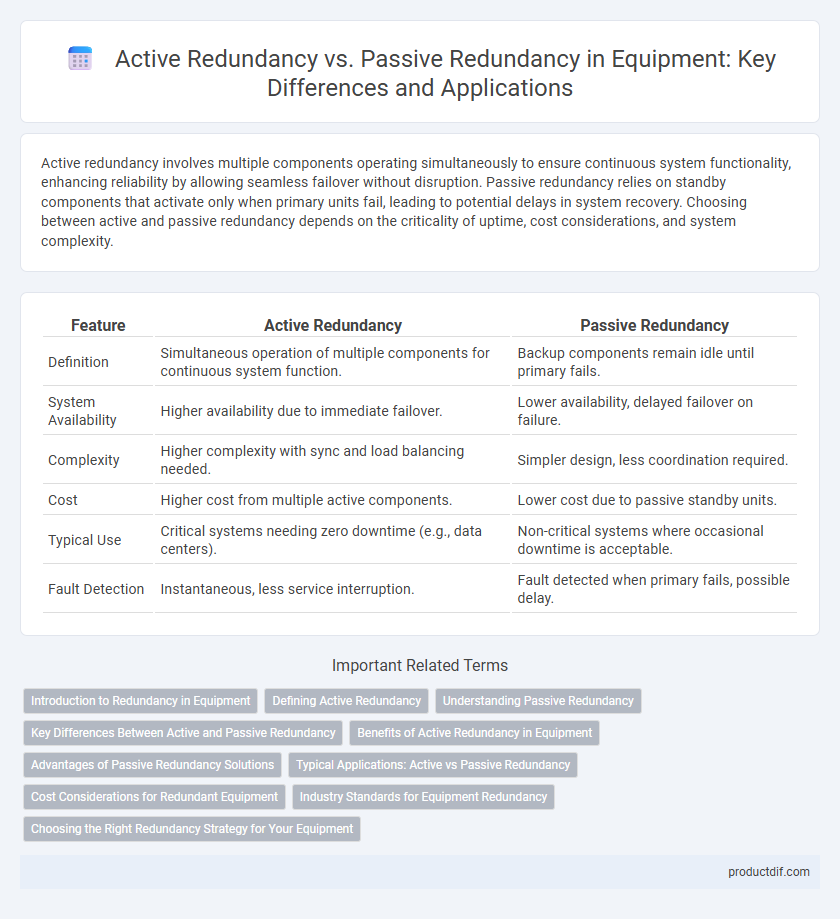

Table of Comparison

| Feature | Active Redundancy | Passive Redundancy |

|---|---|---|

| Definition | Simultaneous operation of multiple components for continuous system function. | Backup components remain idle until primary fails. |

| System Availability | Higher availability due to immediate failover. | Lower availability, delayed failover on failure. |

| Complexity | Higher complexity with sync and load balancing needed. | Simpler design, less coordination required. |

| Cost | Higher cost from multiple active components. | Lower cost due to passive standby units. |

| Typical Use | Critical systems needing zero downtime (e.g., data centers). | Non-critical systems where occasional downtime is acceptable. |

| Fault Detection | Instantaneous, less service interruption. | Fault detected when primary fails, possible delay. |

Introduction to Redundancy in Equipment

Redundancy in equipment ensures continuous operation by incorporating backup components that minimize downtime during failures. Active redundancy involves simultaneous operation of primary and backup systems, allowing immediate failover without interruption, commonly used in critical systems like power supplies or communication networks. Passive redundancy utilizes standby backups activated only upon primary system failure, optimizing resource use and cost in less time-sensitive applications.

Defining Active Redundancy

Active redundancy involves multiple components operating simultaneously to perform the same function, ensuring continuous system operation even if one component fails. This approach enhances reliability by allowing seamless load sharing and immediate fault detection without system downtime. Active redundancy is commonly used in critical equipment such as data centers, aerospace systems, and telecommunications to maximize uptime and performance.

Understanding Passive Redundancy

Passive redundancy involves duplicating equipment components that remain inactive until a failure occurs, ensuring backup parts seamlessly replace faulty ones without interrupting operation. Unlike active redundancy, where all components run simultaneously, passive redundancy conserves energy and reduces wear by engaging backups only when necessary. This approach improves system reliability and lowers maintenance costs by minimizing unnecessary resource utilization.

Key Differences Between Active and Passive Redundancy

Active redundancy involves multiple components operating simultaneously to ensure continuous system performance, whereas passive redundancy relies on standby components that activate only upon failure of the primary unit. Active systems provide real-time fault tolerance with minimal downtime, while passive redundancy often results in brief interruptions during the switch-over process. The choice between active and passive redundancy depends on the criticality of uptime, system complexity, and cost considerations in equipment design.

Benefits of Active Redundancy in Equipment

Active redundancy in equipment enhances system reliability by continuously operating multiple components simultaneously, ensuring seamless functionality if one fails. This approach minimizes downtime and maintains consistent performance, crucial in critical applications such as aerospace, data centers, and medical devices. Active redundancy enables real-time fault detection and immediate switchover, optimizing maintenance schedules and reducing operational risks.

Advantages of Passive Redundancy Solutions

Passive redundancy solutions offer simpler implementation and lower maintenance costs compared to active redundancy systems. They minimize power consumption by operating backup components only when primary units fail, enhancing overall energy efficiency in equipment. These solutions improve reliability without the complexity of real-time synchronization between active and standby components.

Typical Applications: Active vs Passive Redundancy

Active redundancy is commonly employed in critical systems such as aerospace, telecommunications, and data centers where continuous operation and immediate failover are essential to avoid downtime. Passive redundancy suits applications like industrial machinery and consumer electronics where failover can tolerate brief delays and cost efficiency is prioritized. Typical active redundancy setups involve parallel components operating simultaneously, while passive redundancy uses standby components activated only upon failure detection.

Cost Considerations for Redundant Equipment

Active redundancy requires higher initial investment due to simultaneous operation of multiple components, increasing both capital and energy costs. Passive redundancy, with standby components activated only upon failure, offers lower ongoing expenses but may incur costs associated with slower recovery times and potential downtime. Evaluating total cost of ownership involves balancing upfront expenditures against maintenance, downtime, and reliability requirements in mission-critical equipment.

Industry Standards for Equipment Redundancy

Industry standards such as IEC 61508 and ISO 13849 define Active redundancy as systems where multiple components operate simultaneously to ensure continuous functionality, while Passive redundancy involves standby components activated only upon primary failure. Active redundancy is preferred in critical industrial equipment to minimize downtime, supported by standards emphasizing real-time fault detection and seamless switchover. Passive redundancy is commonly applied where cost efficiency is prioritized, with industry protocols addressing delayed activation and periodic testing to ensure reliability during equipment failure.

Choosing the Right Redundancy Strategy for Your Equipment

Active redundancy ensures continuous operation by running multiple components simultaneously, providing immediate backup in case of failure. Passive redundancy relies on a standby component that activates only when the primary fails, optimizing resource use but introducing a brief downtime risk. Selecting the appropriate redundancy strategy depends on the criticality of equipment uptime, cost constraints, and maintenance capabilities.

Active redundancy vs Passive redundancy Infographic

productdif.com

productdif.com