Cast iron molds offer superior durability and heat retention, making them ideal for high-temperature casting processes and extended production runs. Aluminum molds provide faster cooling rates and lighter weight, which enhances production speed and ease of handling in industries requiring quick turnaround. Choosing between cast iron and aluminum molds depends on balancing longevity and thermal conductivity against production efficiency and weight constraints.

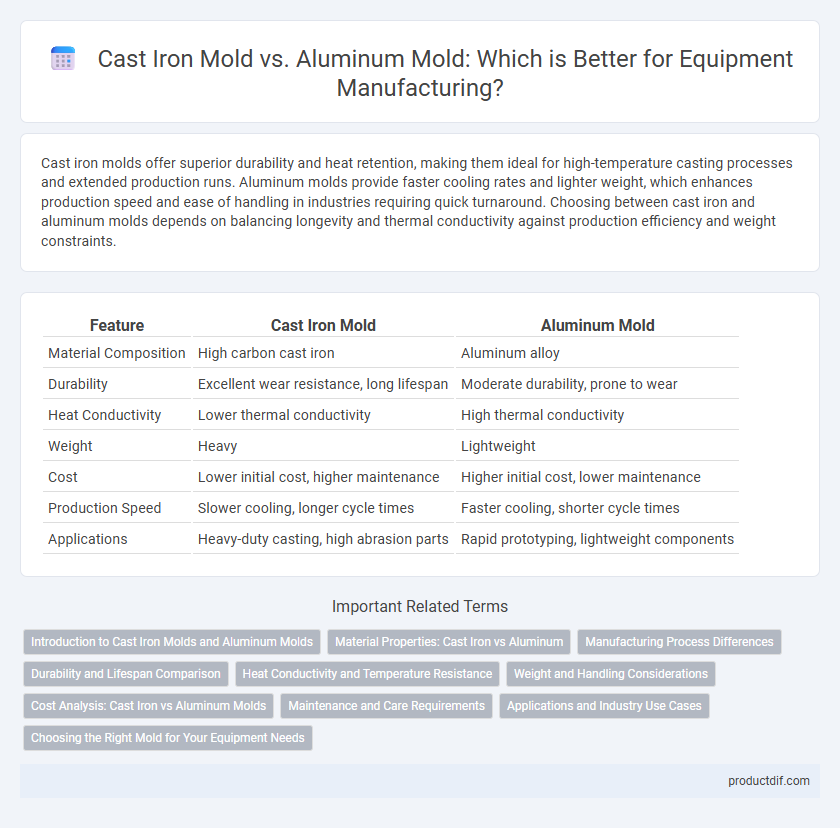

Table of Comparison

| Feature | Cast Iron Mold | Aluminum Mold |

|---|---|---|

| Material Composition | High carbon cast iron | Aluminum alloy |

| Durability | Excellent wear resistance, long lifespan | Moderate durability, prone to wear |

| Heat Conductivity | Lower thermal conductivity | High thermal conductivity |

| Weight | Heavy | Lightweight |

| Cost | Lower initial cost, higher maintenance | Higher initial cost, lower maintenance |

| Production Speed | Slower cooling, longer cycle times | Faster cooling, shorter cycle times |

| Applications | Heavy-duty casting, high abrasion parts | Rapid prototyping, lightweight components |

Introduction to Cast Iron Molds and Aluminum Molds

Cast iron molds offer exceptional durability and thermal stability, making them ideal for high-temperature casting processes and heavy-duty applications. Aluminum molds provide superior heat conductivity and are lightweight, which allows for faster cycle times and increased production efficiency in precision manufacturing. Selecting between cast iron and aluminum molds depends on factors such as casting complexity, production volume, and required mold lifespan.

Material Properties: Cast Iron vs Aluminum

Cast iron molds exhibit superior wear resistance and dimensional stability under high temperatures due to their high carbon content and ferroalloy composition, making them ideal for heavy-duty casting processes. Aluminum molds offer excellent thermal conductivity and lightweight properties, enabling faster cooling cycles and easier handling, but they have lower hardness and wear resistance compared to cast iron. The choice between cast iron and aluminum molds depends on the balance between durability requirements and production speed in manufacturing operations.

Manufacturing Process Differences

Cast iron molds offer superior durability and heat retention, making them ideal for high-volume manufacturing requiring consistent thermal conditions, while aluminum molds provide faster cooling rates and quicker cycle times due to their excellent thermal conductivity. The manufacturing process for cast iron molds involves longer machining and heat treatment phases to achieve desired hardness and wear resistance, contrasted with aluminum molds which require less extensive machining but demand precise surface finishing to prevent defects. These differences in mold material affect not only the production speed but also maintenance frequency and overall tooling costs in the manufacturing workflow.

Durability and Lifespan Comparison

Cast iron molds exhibit superior durability due to their high resistance to wear, corrosion, and thermal shock, often lasting several decades under consistent use. Aluminum molds, while offering excellent thermal conductivity and faster cycle times, typically have a shorter lifespan because they are more susceptible to surface wear and deformation under high pressure. Manufacturers prioritize cast iron molds for long-term, heavy-duty applications, whereas aluminum molds suit rapid prototyping and low to mid-volume production runs.

Heat Conductivity and Temperature Resistance

Cast iron molds exhibit lower heat conductivity, allowing for gradual and even heat distribution that reduces thermal shock and extends mold lifespan. Aluminum molds offer superior heat conductivity, enabling faster heating and cooling cycles, which increases production efficiency but may lead to quicker wear at high temperatures. Cast iron provides higher temperature resistance, suitable for prolonged exposure to intense heat, while aluminum molds perform best under moderate temperature conditions to avoid deformation.

Weight and Handling Considerations

Cast iron molds are significantly heavier than aluminum molds, impacting handling and transportation efficiency in manufacturing settings. The high density of cast iron increases durability but requires more robust equipment and labor for movement. Aluminum molds offer lightweight advantages, facilitating easier handling and faster setup without compromising essential structural integrity.

Cost Analysis: Cast Iron vs Aluminum Molds

Cast iron molds have a higher initial cost due to their heavy material and longer manufacturing time, but they offer superior durability and longevity, reducing replacement frequency. Aluminum molds cost less upfront and provide excellent thermal conductivity, resulting in faster cycle times and increased production efficiency. Analyzing overall cost effectiveness depends on production volume, with cast iron molds favored for long runs and aluminum molds ideal for short to medium runs.

Maintenance and Care Requirements

Cast iron molds require regular seasoning to prevent rust and maintain their non-stick surface, with thorough cleaning and drying after each use to avoid corrosion. Aluminum molds demand careful handling to prevent dents and scratches, with routine cleaning using mild detergents and avoiding abrasive materials to preserve their smooth surface. Both types benefit from proper storage in dry environments, but cast iron generally needs more intensive maintenance to ensure longevity compared to aluminum.

Applications and Industry Use Cases

Cast iron molds are favored in heavy-duty manufacturing sectors like automotive and industrial machinery due to their durability and high heat retention, ideal for large-scale production of complex metal parts. Aluminum molds are widely used in aerospace, electronics, and consumer goods industries where lightweight, fast cooling, and high thermal conductivity enable rapid prototyping and precise casting of intricate components. Both materials serve distinct applications, with cast iron excelling in strength-intensive processes and aluminum optimizing speed and detail accuracy in production.

Choosing the Right Mold for Your Equipment Needs

Cast iron molds offer exceptional durability and heat retention, making them ideal for heavy-duty industrial equipment requiring consistent thermal performance. Aluminum molds provide lightweight versatility and faster heat dissipation, suited for high-volume production where quick cycle times are critical. Selecting the right mold depends on balancing factors like production speed, equipment lifespan, and thermal conductivity to match specific operational requirements.

Cast iron mold vs Aluminum mold Infographic

productdif.com

productdif.com