Maximizing throughput requires equipment to operate at high speeds without frequent interruptions, while maintaining uptime depends on minimizing downtime through effective maintenance and rapid issue resolution. Balancing throughput and uptime is essential for optimizing overall operational efficiency, as excessive focus on one can negatively impact the other. Efficient equipment management ensures reliable performance and high production output without compromising machine availability.

Table of Comparison

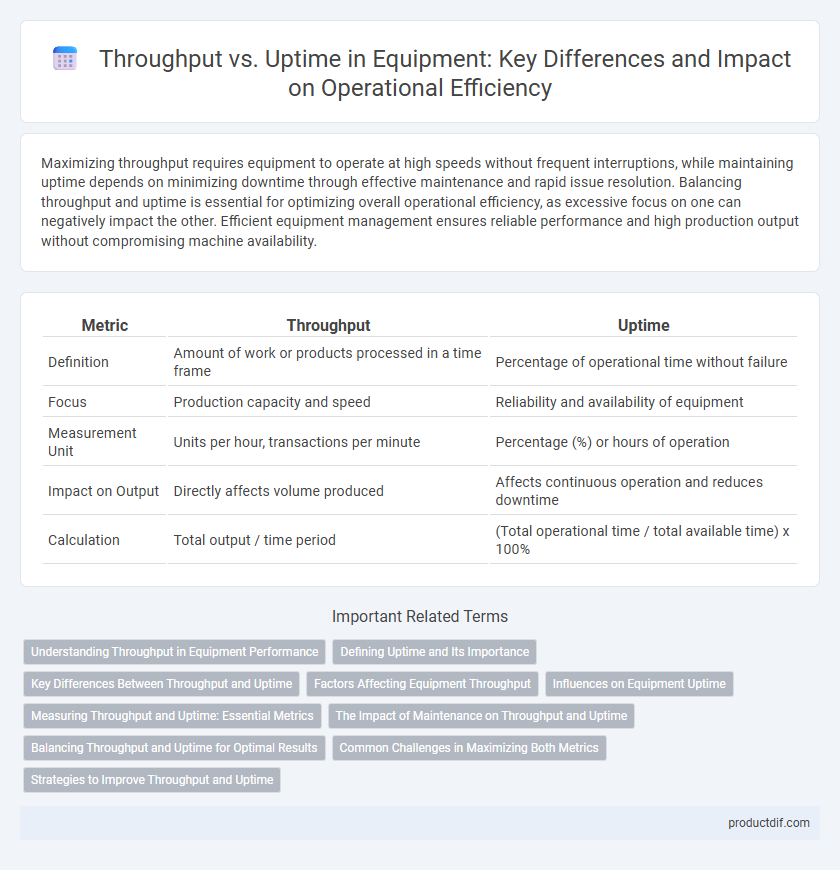

| Metric | Throughput | Uptime |

|---|---|---|

| Definition | Amount of work or products processed in a time frame | Percentage of operational time without failure |

| Focus | Production capacity and speed | Reliability and availability of equipment |

| Measurement Unit | Units per hour, transactions per minute | Percentage (%) or hours of operation |

| Impact on Output | Directly affects volume produced | Affects continuous operation and reduces downtime |

| Calculation | Total output / time period | (Total operational time / total available time) x 100% |

Understanding Throughput in Equipment Performance

Throughput in equipment performance measures the volume of units processed within a given time, directly impacting productivity and operational efficiency. Higher throughput indicates faster production rates, which can lead to increased revenue and reduced lead times. Understanding throughput helps identify bottlenecks and optimize equipment settings for maximal output without sacrificing quality.

Defining Uptime and Its Importance

Uptime refers to the total time equipment operates without failure, directly impacting productivity and operational efficiency. High uptime ensures maximum throughput by minimizing downtime losses and maintaining continuous production flow. Prioritizing equipment uptime reduces maintenance costs and supports consistent output in manufacturing and industrial settings.

Key Differences Between Throughput and Uptime

Throughput measures the amount of product or material processed by equipment within a specific time frame, reflecting operational efficiency and capacity. Uptime indicates the total time equipment is operational and available for production, emphasizing reliability and maintenance effectiveness. Key differences include throughput focusing on output quantity, while uptime prioritizes equipment availability and consistent performance.

Factors Affecting Equipment Throughput

Equipment throughput depends heavily on uptime, with factors such as maintenance schedules, operator efficiency, and equipment age significantly impacting performance. Frequent breakdowns and delayed repairs decrease effective operating time, while proper calibration and timely preventive maintenance enhance continuous operation. Environmental conditions and quality of input materials also influence throughput by affecting machine speed and reliability.

Influences on Equipment Uptime

Equipment uptime is primarily influenced by factors such as maintenance quality, operator skill, and environmental conditions. High throughput demands can accelerate wear and tear, increasing the likelihood of equipment failure and reducing uptime. Optimizing maintenance schedules and monitoring operational stress are essential to balancing throughput with reliable equipment performance.

Measuring Throughput and Uptime: Essential Metrics

Measuring throughput involves quantifying the total output produced by equipment within a specific time frame, reflecting operational efficiency and productivity. Uptime is calculated as the percentage of time equipment remains operational and available for use, indicating reliability and maintenance effectiveness. Together, these metrics provide a comprehensive view of equipment performance, guiding optimization strategies and minimizing downtime.

The Impact of Maintenance on Throughput and Uptime

Regular maintenance directly enhances equipment uptime by reducing breakdowns and prolonging operational availability. Improved uptime facilitates higher throughput as machines function consistently without interruptions, maximizing production capacity. Neglecting maintenance increases downtime, thereby diminishing throughput and overall equipment effectiveness.

Balancing Throughput and Uptime for Optimal Results

Balancing throughput and uptime is critical for maximizing equipment efficiency and overall productivity. High throughput demands continuous operation, but excessive wear can reduce uptime, leading to costly downtime and maintenance. Implementing predictive maintenance strategies and real-time monitoring ensures optimal throughput while maintaining equipment reliability and minimizing interruptions.

Common Challenges in Maximizing Both Metrics

Maximizing throughput and uptime simultaneously often faces challenges such as equipment wear and unexpected breakdowns, which reduce operational efficiency. High throughput demands can accelerate component fatigue, leading to increased maintenance and downtime. Balancing production speed with preventive maintenance schedules is critical to minimizing disruptions and maintaining consistent performance metrics.

Strategies to Improve Throughput and Uptime

Maximizing throughput and uptime requires implementing predictive maintenance technologies to reduce unexpected equipment failures and scheduling regular inspections to ensure optimal performance. Integrating automation and real-time monitoring systems helps identify bottlenecks and operational inefficiencies, enabling timely adjustments that enhance production flow. Investing in high-quality spare parts and employee training further minimizes downtime and supports consistent throughput levels.

Throughput vs Uptime Infographic

productdif.com

productdif.com