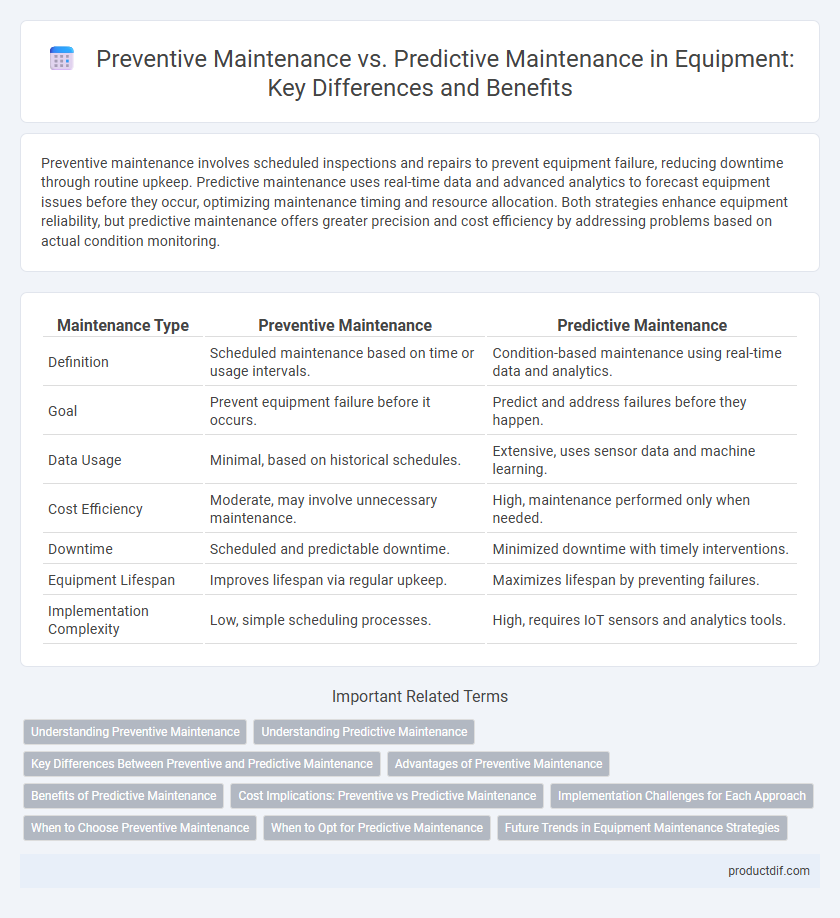

Preventive maintenance involves scheduled inspections and repairs to prevent equipment failure, reducing downtime through routine upkeep. Predictive maintenance uses real-time data and advanced analytics to forecast equipment issues before they occur, optimizing maintenance timing and resource allocation. Both strategies enhance equipment reliability, but predictive maintenance offers greater precision and cost efficiency by addressing problems based on actual condition monitoring.

Table of Comparison

| Maintenance Type | Preventive Maintenance | Predictive Maintenance |

|---|---|---|

| Definition | Scheduled maintenance based on time or usage intervals. | Condition-based maintenance using real-time data and analytics. |

| Goal | Prevent equipment failure before it occurs. | Predict and address failures before they happen. |

| Data Usage | Minimal, based on historical schedules. | Extensive, uses sensor data and machine learning. |

| Cost Efficiency | Moderate, may involve unnecessary maintenance. | High, maintenance performed only when needed. |

| Downtime | Scheduled and predictable downtime. | Minimized downtime with timely interventions. |

| Equipment Lifespan | Improves lifespan via regular upkeep. | Maximizes lifespan by preventing failures. |

| Implementation Complexity | Low, simple scheduling processes. | High, requires IoT sensors and analytics tools. |

Understanding Preventive Maintenance

Preventive maintenance involves scheduled inspections and servicing of equipment to prevent unexpected failures and extend asset lifespan. This approach relies on predetermined intervals based on time or usage, ensuring components are replaced or repaired before deterioration leads to breakdowns. Regular preventive maintenance reduces downtime and improves operational efficiency by maintaining equipment in optimal condition.

Understanding Predictive Maintenance

Predictive maintenance leverages real-time data collection and advanced analytics to forecast equipment failures before they occur, minimizing unplanned downtime and reducing maintenance costs. Sensors and IoT devices continuously monitor machine conditions such as vibration, temperature, and pressure, enabling precise scheduling of maintenance activities only when necessary. This approach enhances asset reliability and extends equipment lifespan by addressing issues proactively rather than routinely as in preventive maintenance.

Key Differences Between Preventive and Predictive Maintenance

Preventive maintenance involves scheduled inspections and replacements based on time or usage intervals to reduce equipment failures, while predictive maintenance utilizes real-time data and condition monitoring to predict when maintenance should be performed. Key differences include the reliance on historical data in preventive maintenance versus the use of advanced sensors and analytics in predictive maintenance for precise failure detection. Predictive maintenance optimizes maintenance costs by preventing unnecessary tasks and minimizing unplanned downtime, whereas preventive maintenance follows a fixed schedule regardless of actual equipment condition.

Advantages of Preventive Maintenance

Preventive maintenance extends equipment lifespan by scheduling regular inspections and replacements before breakdowns occur, reducing unexpected downtime. It ensures consistent operational efficiency and safety through routine upkeep based on time or usage intervals. This approach requires less complex technology and data analysis, making it cost-effective and easier to implement across diverse equipment types.

Benefits of Predictive Maintenance

Predictive maintenance leverages real-time data and advanced analytics to anticipate equipment failures before they occur, reducing unplanned downtime and optimizing maintenance schedules. This approach extends equipment lifespan by addressing issues precisely when needed, minimizing unnecessary part replacements and labor costs. Enhanced operational efficiency and reduced maintenance expenses position predictive maintenance as a superior strategy compared to traditional preventive methods.

Cost Implications: Preventive vs Predictive Maintenance

Preventive maintenance involves scheduled inspections and part replacements to avoid equipment failure, often resulting in higher labor and material costs due to routine servicing regardless of actual equipment condition. Predictive maintenance uses real-time data and condition monitoring technologies like IoT sensors and vibration analysis to predict equipment failures, reducing unnecessary maintenance activities and lowering overall operational costs. While predictive maintenance requires initial investment in technology and training, it typically leads to significant long-term savings by minimizing downtime and optimizing resource allocation.

Implementation Challenges for Each Approach

Preventive maintenance faces implementation challenges such as scheduling downtime, ensuring accurate maintenance intervals, and managing labor costs without real-time data insights. Predictive maintenance requires advanced sensor integration, reliable data analytics infrastructure, and skilled personnel to interpret complex performance indicators. Both approaches demand significant upfront investment, but predictive maintenance offers higher long-term efficiency through condition-based interventions.

When to Choose Preventive Maintenance

Preventive maintenance is ideal when equipment operates under consistent conditions and failure patterns are well understood, allowing for scheduled inspections and replacements to minimize downtime. It is cost-effective for machinery with predictable wear and critical systems where unexpected breakdowns must be avoided. Organizations should choose preventive maintenance when historical data supports routine upkeep intervals to ensure reliability and extend equipment lifespan.

When to Opt for Predictive Maintenance

Predictive maintenance is ideal when equipment is critical to operations and downtime costs are high, as it uses real-time data and advanced analytics to forecast failures before they occur. This approach optimizes maintenance schedules by targeting only assets showing early signs of wear, reducing unnecessary inspections and part replacements. Industries such as manufacturing, aviation, and energy benefit significantly by improving asset reliability and extending equipment lifespan through predictive maintenance.

Future Trends in Equipment Maintenance Strategies

Future trends in equipment maintenance strategies emphasize the integration of AI-driven predictive analytics to enhance accuracy in fault detection and reduce downtime. Preventive maintenance schedules are evolving with real-time sensor data to optimize intervals, minimizing unnecessary servicing and extending equipment lifespan. The convergence of IoT, machine learning, and cloud computing will drive smarter, more cost-effective maintenance approaches, transforming traditional equipment management paradigms.

Preventive maintenance vs Predictive maintenance Infographic

productdif.com

productdif.com