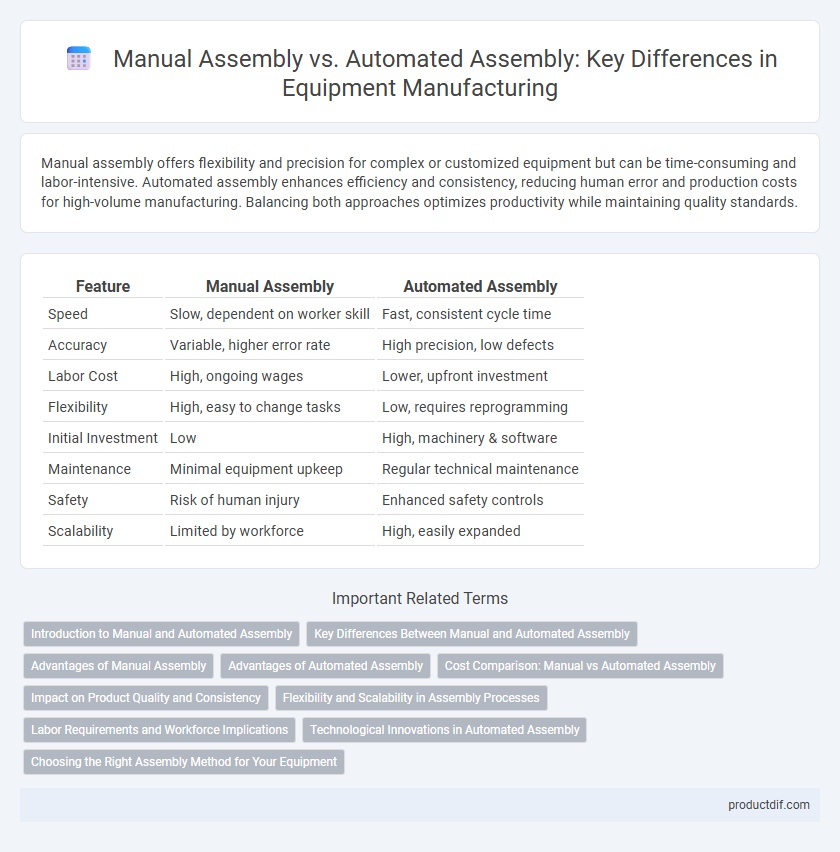

Manual assembly offers flexibility and precision for complex or customized equipment but can be time-consuming and labor-intensive. Automated assembly enhances efficiency and consistency, reducing human error and production costs for high-volume manufacturing. Balancing both approaches optimizes productivity while maintaining quality standards.

Table of Comparison

| Feature | Manual Assembly | Automated Assembly |

|---|---|---|

| Speed | Slow, dependent on worker skill | Fast, consistent cycle time |

| Accuracy | Variable, higher error rate | High precision, low defects |

| Labor Cost | High, ongoing wages | Lower, upfront investment |

| Flexibility | High, easy to change tasks | Low, requires reprogramming |

| Initial Investment | Low | High, machinery & software |

| Maintenance | Minimal equipment upkeep | Regular technical maintenance |

| Safety | Risk of human injury | Enhanced safety controls |

| Scalability | Limited by workforce | High, easily expanded |

Introduction to Manual and Automated Assembly

Manual assembly relies on skilled workers to perform precise tasks using hand tools and standard equipment, ensuring flexibility and adaptability in complex or customized production processes. Automated assembly employs programmable machines and robotics to increase production speed, consistency, and accuracy, ideal for high-volume manufacturing with repetitive operations. Choosing between manual and automated assembly depends on factors like production scale, product complexity, and cost-efficiency requirements.

Key Differences Between Manual and Automated Assembly

Manual assembly relies on human labor to put together components, offering flexibility and adaptability for custom or small-scale production. Automated assembly uses machinery and robotics to enhance speed, precision, and consistency, ideal for large-scale manufacturing. Key differences include labor cost, error rate, scalability, and production speed, where automated processes typically reduce errors and increase volume but require higher initial investment.

Advantages of Manual Assembly

Manual assembly offers superior flexibility in handling complex or customized equipment components that automated systems may struggle to process accurately. It allows for immediate quality control adjustments and precise craftsmanship, reducing the risk of defects in small-batch or intricate productions. Skilled operators can adapt to design changes and troubleshoot assembly issues on the spot, enhancing overall product reliability and customization.

Advantages of Automated Assembly

Automated assembly improves production speed and consistency, reducing human error and increasing overall product quality. It enables cost savings through lower labor expenses and minimizes downtime with continuous operation capabilities. Advanced robotics and machine vision systems enhance precision and adaptability for complex manufacturing processes.

Cost Comparison: Manual vs Automated Assembly

Manual assembly typically involves higher labor costs due to intensive human involvement and longer production times, leading to increased overtime expenses and variability in output. Automated assembly requires significant upfront investment in machinery and programming but reduces per-unit labor costs and enhances scalability, resulting in lower long-term operational expenses. Evaluating the total cost of ownership reveals that automation generally yields greater cost efficiency for high-volume production, whereas manual assembly may be more cost-effective for low-volume or highly customized products.

Impact on Product Quality and Consistency

Manual assembly allows for detailed craftsmanship but often results in variability in product quality and consistency due to human error and fatigue. Automated assembly utilizes precision machinery, ensuring uniformity and high repeatability, which significantly reduces defects and enhances overall product reliability. Integration of advanced sensors and robotics in automated systems delivers consistent quality control, outperforming manual processes in scaling production while maintaining stringent quality standards.

Flexibility and Scalability in Assembly Processes

Manual assembly offers high flexibility by allowing easy adaptation to design changes and customization for small production runs, making it ideal for complex or bespoke products. Automated assembly excels in scalability, delivering consistent quality and high throughput in large-volume manufacturing, though it may require significant reprogramming or tooling adjustments to accommodate new products. Integrating both methods can optimize production efficiency by balancing customization needs with mass production capabilities.

Labor Requirements and Workforce Implications

Manual assembly demands a higher number of skilled laborers, leading to increased training costs and potential variability in output quality. Automated assembly significantly reduces labor requirements by utilizing machines programmed for precision and consistency, thus minimizing human error and fatigue. Workforce implications include a shift toward technical roles focused on machine oversight and maintenance, necessitating reskilling and adaptation to evolving manufacturing technologies.

Technological Innovations in Automated Assembly

Technological innovations in automated assembly have revolutionized equipment efficiency by integrating advanced robotics, AI-driven quality control, and real-time data analytics, significantly reducing production errors and cycle times. Precision sensors and machine learning algorithms enable adaptive adjustments during assembly, improving product consistency and minimizing downtime. These advancements outperform traditional manual assembly methods by enhancing scalability and lowering labor costs in manufacturing environments.

Choosing the Right Assembly Method for Your Equipment

Selecting the right assembly method for your equipment depends on production volume, complexity, and cost constraints. Manual assembly offers flexibility and precision for low-volume or intricate tasks, while automated assembly excels in high-volume, consistent output with reduced labor costs. Evaluating these factors ensures optimal efficiency and quality in your manufacturing process.

Manual assembly vs Automated assembly Infographic

productdif.com

productdif.com