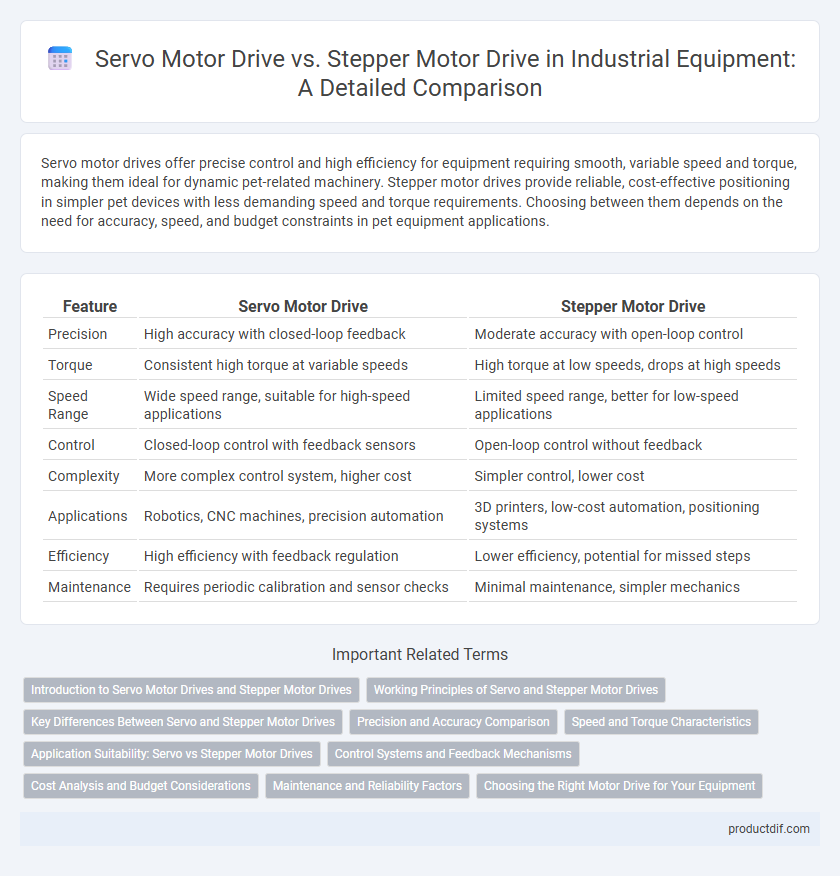

Servo motor drives offer precise control and high efficiency for equipment requiring smooth, variable speed and torque, making them ideal for dynamic pet-related machinery. Stepper motor drives provide reliable, cost-effective positioning in simpler pet devices with less demanding speed and torque requirements. Choosing between them depends on the need for accuracy, speed, and budget constraints in pet equipment applications.

Table of Comparison

| Feature | Servo Motor Drive | Stepper Motor Drive |

|---|---|---|

| Precision | High accuracy with closed-loop feedback | Moderate accuracy with open-loop control |

| Torque | Consistent high torque at variable speeds | High torque at low speeds, drops at high speeds |

| Speed Range | Wide speed range, suitable for high-speed applications | Limited speed range, better for low-speed applications |

| Control | Closed-loop control with feedback sensors | Open-loop control without feedback |

| Complexity | More complex control system, higher cost | Simpler control, lower cost |

| Applications | Robotics, CNC machines, precision automation | 3D printers, low-cost automation, positioning systems |

| Efficiency | High efficiency with feedback regulation | Lower efficiency, potential for missed steps |

| Maintenance | Requires periodic calibration and sensor checks | Minimal maintenance, simpler mechanics |

Introduction to Servo Motor Drives and Stepper Motor Drives

Servo motor drives utilize closed-loop control systems, providing precise positioning, velocity, and torque by continuously monitoring feedback from encoders or resolvers. Stepper motor drives operate on open-loop control principles, moving in discrete steps with fixed angles, ideal for applications requiring simple, low-cost, and reliable positioning without feedback devices. The choice between servo and stepper drives depends on requirements for torque, speed, accuracy, and system complexity.

Working Principles of Servo and Stepper Motor Drives

Servo motor drives operate using precise feedback control via encoders or resolvers to continuously adjust the motor position, speed, and torque, enabling high accuracy and dynamic response in automation systems. Stepper motor drives function by sending fixed pulses to the motor coils, causing the rotor to move in discrete steps with open-loop control, which simplifies control but may sacrifice precision under varying loads. The closed-loop feedback in servo drives contrasts with the open-loop step control of stepper drives, impacting performance in applications requiring high torque and positional accuracy.

Key Differences Between Servo and Stepper Motor Drives

Servo motor drives provide precise control of speed, position, and torque using feedback systems, enabling high dynamic performance and smooth operation in complex applications. Stepper motor drives operate without feedback, moving in fixed increments for simple, open-loop control suitable for low to moderate speed and torque demands. Key differences include servo drives' closed-loop accuracy and adaptability versus stepper drives' cost-effectiveness and straightforward control for less demanding positioning tasks.

Precision and Accuracy Comparison

Servo motor drives offer superior precision and accuracy due to their closed-loop feedback systems that continuously monitor position and adjust torque accordingly. Stepper motor drives operate on an open-loop control system, which can lead to missed steps and reduced accuracy under varying loads. High-precision applications benefit from servo drives' ability to maintain exact positioning with minimal error, while stepper drives are suitable for simpler, less demanding tasks.

Speed and Torque Characteristics

Servo motor drives offer high-speed capabilities with precise torque control over a wide range, making them ideal for dynamic applications requiring rapid acceleration and deceleration. Stepper motor drives provide consistent torque at low speeds but experience torque drop-off at higher speeds, limiting their performance in fast operations. The choice between the two depends on the need for speed variability and torque stability, where servo drives excel in high-speed precision and stepper drives favor simpler, low-speed tasks.

Application Suitability: Servo vs Stepper Motor Drives

Servo motor drives excel in high-precision and dynamic applications such as robotics, CNC machines, and automated manufacturing due to their closed-loop feedback system and superior torque control. Stepper motor drives are ideal for simpler, cost-sensitive applications like 3D printers, small conveyors, and positioning systems requiring open-loop control with moderate speed and torque. The choice depends on factors including the need for accuracy, speed, load capacity, and system complexity in industrial automation.

Control Systems and Feedback Mechanisms

Servo motor drives feature closed-loop control systems with continuous feedback via encoders or resolvers, enabling precise position, speed, and torque regulation. Stepper motor drives typically operate on open-loop control without feedback, relying on predetermined step signals for position control, which can lead to missed steps under load. The advanced feedback mechanisms in servo systems provide higher accuracy and dynamic response, essential for complex automation tasks.

Cost Analysis and Budget Considerations

Servo motor drives generally have higher upfront costs compared to stepper motor drives due to their complex feedback systems and advanced control capabilities. Stepper motors offer a more cost-effective solution for applications requiring moderate precision and simpler control, reducing both initial investment and maintenance expenses. Budget considerations should weigh the total cost of ownership, including energy consumption and system integration, where servo drives may offer long-term savings despite higher initial costs.

Maintenance and Reliability Factors

Servo motor drives require regular calibration and feedback system checks to maintain optimal performance, while stepper motor drives are generally simpler with lower maintenance needs due to their open-loop control design. Servo drives offer higher reliability in dynamic applications through precise position and speed control, but their complexity can increase the risk of component wear and failure. Stepper motors provide robust performance with fewer electronic components, reducing long-term maintenance costs and improving reliability in low-to-moderate precision environments.

Choosing the Right Motor Drive for Your Equipment

Selecting the right motor drive for your equipment depends on precision, speed, and torque requirements; servo motor drives offer high efficiency, closed-loop control, and superior accuracy, ideal for complex motion control applications. Stepper motor drives provide cost-effective, open-loop operation with reliable performance for simpler, low to medium torque tasks where precise positioning is essential without feedback systems. Evaluating load dynamics, control complexity, and budget constraints helps determine whether a servo or stepper motor drive best suits your specific machinery needs.

Servo motor drive vs Stepper motor drive Infographic

productdif.com

productdif.com