Hard automation involves fixed sequences of operations designed for high-volume, repetitive tasks, delivering maximum efficiency and minimal changeover time. Flexible automation uses programmable machines capable of adapting to different products and production processes, allowing quick transitions and customization without extensive downtime. Choosing between hard and flexible automation depends on production volume, product variety, and the need for operational adaptability.

Table of Comparison

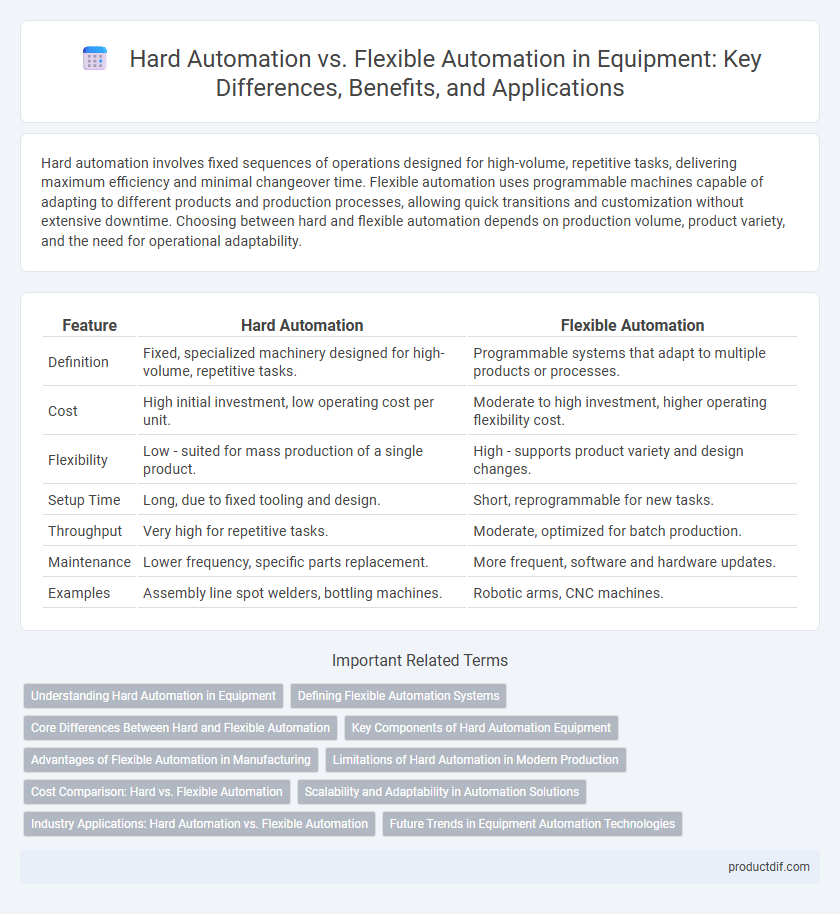

| Feature | Hard Automation | Flexible Automation |

|---|---|---|

| Definition | Fixed, specialized machinery designed for high-volume, repetitive tasks. | Programmable systems that adapt to multiple products or processes. |

| Cost | High initial investment, low operating cost per unit. | Moderate to high investment, higher operating flexibility cost. |

| Flexibility | Low - suited for mass production of a single product. | High - supports product variety and design changes. |

| Setup Time | Long, due to fixed tooling and design. | Short, reprogrammable for new tasks. |

| Throughput | Very high for repetitive tasks. | Moderate, optimized for batch production. |

| Maintenance | Lower frequency, specific parts replacement. | More frequent, software and hardware updates. |

| Examples | Assembly line spot welders, bottling machines. | Robotic arms, CNC machines. |

Understanding Hard Automation in Equipment

Hard automation in equipment involves fixed, specialized machines designed for high-volume, repetitive tasks with minimal variation in production processes. These systems typically use dedicated tools and controls optimized for speed and efficiency, resulting in lower unit costs but limited adaptability to product changes. Industries such as automotive manufacturing benefit from hard automation due to its precision and consistent output in mass production environments.

Defining Flexible Automation Systems

Flexible automation systems are designed to handle a variety of tasks and product types without the need for extensive reprogramming or manual intervention, enabling rapid adaptation to changing production requirements. These systems utilize programmable robots, CNC machines, and intelligent control software to switch seamlessly between different operations, enhancing efficiency in manufacturing environments with high product variability. The ability to quickly reconfigure workflows and automate diverse processes distinguishes flexible automation from hard automation, which is specialized for single tasks.

Core Differences Between Hard and Flexible Automation

Hard automation utilizes specialized equipment designed for high-volume production of a single product, offering maximum efficiency but minimal adaptability. Flexible automation employs programmable machines capable of handling varying product types and batch sizes, providing versatility and faster changeover times. Core differences include rigidity in system design, level of customization, and response to market demand fluctuations.

Key Components of Hard Automation Equipment

Hard automation equipment relies on dedicated mechanical components such as cams, gears, and conveyors designed for high-volume, repetitive tasks with minimal variation. Fixed automation systems utilize specialized tooling, control mechanisms, and transfer devices to ensure precise, consistent operation without the need for complex software or reprogramming. These key components enable optimized production efficiency but lack the adaptability found in flexible automation solutions.

Advantages of Flexible Automation in Manufacturing

Flexible automation offers significant advantages in manufacturing by enabling rapid adaptation to product changes without extensive retooling, which reduces downtime and increases productivity. It supports a wide variety of tasks through programmable machinery and robotics, enhancing customization while maintaining consistent quality. This adaptability lowers overall production costs and improves responsiveness to market demands compared to hard automation systems.

Limitations of Hard Automation in Modern Production

Hard automation faces limitations in modern production due to its lack of adaptability and high initial setup costs. Its fixed sequence of operations struggles with product variation and quick changeovers, reducing efficiency in dynamic manufacturing environments. These constraints hinder its suitability for industries requiring customization and rapid response to market demands.

Cost Comparison: Hard vs. Flexible Automation

Hard automation requires significant initial capital investment due to dedicated machinery and tooling designed for specific tasks, resulting in higher upfront costs but lower per-unit expenses for high-volume production. Flexible automation systems, although more expensive initially because of programmable controls and adaptable components, offer cost efficiency in the long run by reducing changeover times and accommodating varied product designs without major retooling. Evaluating total cost of ownership reveals hard automation is cost-effective for large, repetitive runs, whereas flexible automation optimizes costs for small batch sizes and frequent product modifications.

Scalability and Adaptability in Automation Solutions

Hard automation offers high scalability for mass production with fixed, specialized equipment designed for repetitive tasks. Flexible automation provides superior adaptability, enabling quick reconfiguration to handle varying product types and production volumes. Choosing between these solutions depends on balancing the need for consistent, high-throughput output versus dynamic responsiveness to changing manufacturing requirements.

Industry Applications: Hard Automation vs. Flexible Automation

Hard automation is ideal for high-volume production in industries such as automotive manufacturing, where repetitive tasks and consistent output are required. Flexible automation suits industries like electronics and consumer goods, enabling rapid changeovers to accommodate varying product designs. The choice between hard and flexible automation depends on production volume, product variety, and the need for system adaptability in specific industrial applications.

Future Trends in Equipment Automation Technologies

Future trends in equipment automation technologies emphasize the integration of artificial intelligence and machine learning to enhance both hard and flexible automation systems. Hard automation remains ideal for high-volume, repetitive tasks, while flexible automation gains traction through adaptive robotics and modular equipment, allowing rapid reconfiguration for diverse production needs. Emerging advancements prioritize smart sensors and IoT connectivity, driving predictive maintenance and real-time process optimization.

Hard Automation vs Flexible Automation Infographic

productdif.com

productdif.com