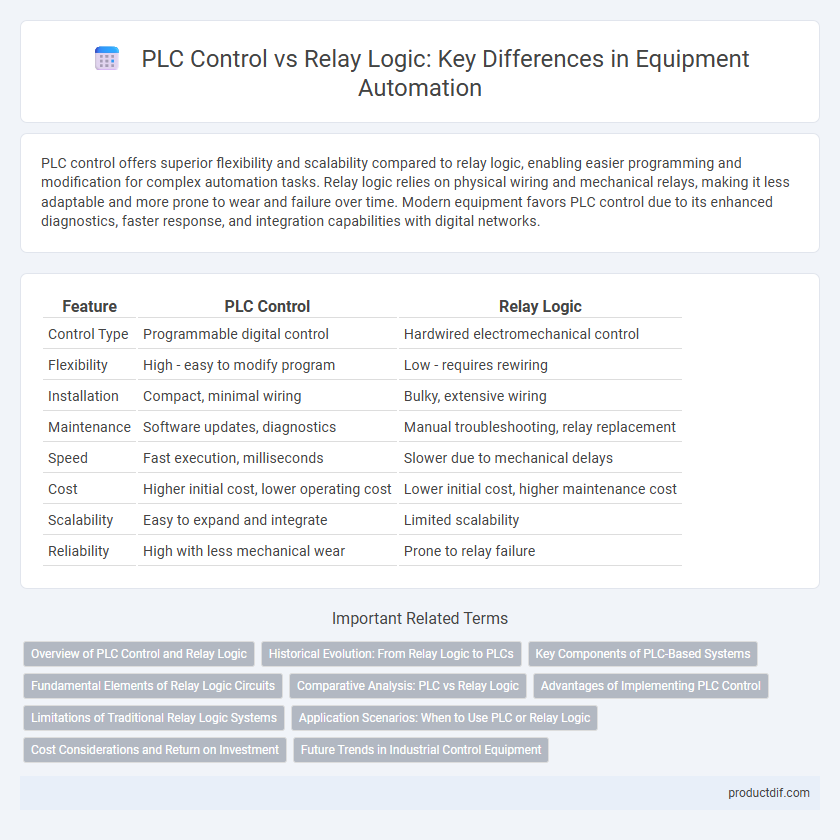

PLC control offers superior flexibility and scalability compared to relay logic, enabling easier programming and modification for complex automation tasks. Relay logic relies on physical wiring and mechanical relays, making it less adaptable and more prone to wear and failure over time. Modern equipment favors PLC control due to its enhanced diagnostics, faster response, and integration capabilities with digital networks.

Table of Comparison

| Feature | PLC Control | Relay Logic |

|---|---|---|

| Control Type | Programmable digital control | Hardwired electromechanical control |

| Flexibility | High - easy to modify program | Low - requires rewiring |

| Installation | Compact, minimal wiring | Bulky, extensive wiring |

| Maintenance | Software updates, diagnostics | Manual troubleshooting, relay replacement |

| Speed | Fast execution, milliseconds | Slower due to mechanical delays |

| Cost | Higher initial cost, lower operating cost | Lower initial cost, higher maintenance cost |

| Scalability | Easy to expand and integrate | Limited scalability |

| Reliability | High with less mechanical wear | Prone to relay failure |

Overview of PLC Control and Relay Logic

PLC control utilizes programmable logic controllers that offer flexible, programmable automation and precise control over complex industrial processes, whereas relay logic relies on fixed, hardwired electromechanical switches for simple, fixed sequence operations. PLCs provide real-time monitoring, easy reprogramming, and integration with digital systems, significantly reducing maintenance and enhancing system reliability compared to relay-based systems. Relay logic is suitable for basic control tasks but lacks scalability, diagnostic capabilities, and adaptability found in PLC control systems.

Historical Evolution: From Relay Logic to PLCs

Relay logic dominated industrial control systems throughout the early 20th century, relying on electromechanical relays for simple, hardwired operations prone to wear and limited flexibility. The introduction of Programmable Logic Controllers (PLCs) in the late 1960s revolutionized automation by enabling software-based control, vastly improving system scalability, reusability, and fault diagnosis. This historical evolution from relay logic to PLCs marked a pivotal shift toward more efficient, programmable, and reliable industrial equipment management.

Key Components of PLC-Based Systems

PLC-based systems primarily consist of a central processing unit (CPU), input/output (I/O) modules, and a programming device that enables flexible and precise control compared to traditional relay logic. The CPU executes control instructions stored in memory, while I/O modules interface with sensors and actuators to monitor and control equipment processes. This modular architecture allows for easy scalability, diagnostics, and integration with automation networks, enhancing system reliability and efficiency.

Fundamental Elements of Relay Logic Circuits

Relay logic circuits primarily consist of electromechanical relays, contacts, coils, and timers, forming the fundamental elements for controlling electrical equipment without digital processing. These components create physical switching operations through the opening and closing of contacts, enabling simple automation based on binary input conditions. Compared to PLC control, relay logic offers straightforward design and robust reliability but lacks the flexibility and programmability essential for complex industrial automation tasks.

Comparative Analysis: PLC vs Relay Logic

PLC control systems offer higher flexibility, faster programming, and easier troubleshooting compared to relay logic, making them ideal for complex automation tasks. Relay logic is typically more robust in harsh environments due to its simple, physical switching components but is limited by slower response times and costly modifications. While PLCs provide scalable integration with modern industrial networks, relay logic excels in applications requiring straightforward, durable, and fail-safe operations.

Advantages of Implementing PLC Control

PLC control offers enhanced flexibility and scalability over traditional relay logic, enabling easy reprogramming and integration with complex automation systems. It improves diagnostic capabilities and reduces maintenance downtime through real-time monitoring and fault detection. PLC systems also provide superior precision and faster processing speeds, optimizing overall equipment efficiency and productivity.

Limitations of Traditional Relay Logic Systems

Traditional relay logic systems face significant limitations such as complex wiring, increased mechanical wear, and limited scalability for automation tasks. They lack the flexibility and programmability found in PLC control, making troubleshooting cumbersome and costly in large-scale or dynamic industrial environments. The inability to easily modify relay logic circuits restricts adaptability to changing process requirements and integration with modern digital control systems.

Application Scenarios: When to Use PLC or Relay Logic

PLC control is ideal for complex automation tasks requiring flexibility, programmability, and easy integration with HMI systems, making it suitable for manufacturing lines with variable processes. Relay logic remains advantageous in simple, fixed-sequence operations where cost-efficiency, robustness, and minimal programming are priorities, such as basic motor starters or lighting controls. In scenarios demanding scalability and remote monitoring, PLCs outperform relay systems, while relay logic excels in harsh environments with electromagnetic interference due to its straightforward design.

Cost Considerations and Return on Investment

PLC control systems typically require higher initial investment compared to relay logic due to advanced programming capabilities and hardware costs. However, PLCs offer greater long-term savings through easier maintenance, faster troubleshooting, and scalability, improving overall return on investment. Relay logic may be more cost-effective for simple, low-volume applications but tends to incur higher labor and modification expenses over time.

Future Trends in Industrial Control Equipment

PLC control systems are increasingly favored over relay logic due to their superior flexibility, scalability, and integration with Industry 4.0 technologies like IoT and cloud computing. Advanced PLCs support real-time data analytics, predictive maintenance, and enhanced cybersecurity, driving smarter, more efficient industrial processes. The transition from relay logic to PLCs accelerates as manufacturers prioritize digital transformation and automation modernization for future-proof industrial control equipment.

PLC control vs relay logic Infographic

productdif.com

productdif.com