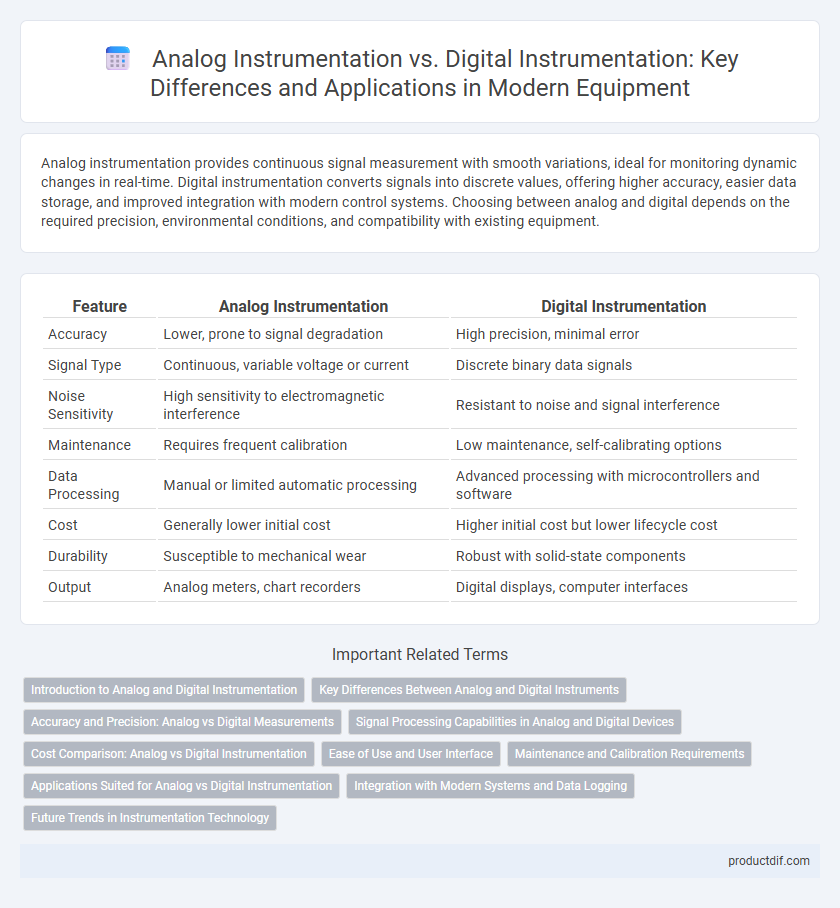

Analog instrumentation provides continuous signal measurement with smooth variations, ideal for monitoring dynamic changes in real-time. Digital instrumentation converts signals into discrete values, offering higher accuracy, easier data storage, and improved integration with modern control systems. Choosing between analog and digital depends on the required precision, environmental conditions, and compatibility with existing equipment.

Table of Comparison

| Feature | Analog Instrumentation | Digital Instrumentation |

|---|---|---|

| Accuracy | Lower, prone to signal degradation | High precision, minimal error |

| Signal Type | Continuous, variable voltage or current | Discrete binary data signals |

| Noise Sensitivity | High sensitivity to electromagnetic interference | Resistant to noise and signal interference |

| Maintenance | Requires frequent calibration | Low maintenance, self-calibrating options |

| Data Processing | Manual or limited automatic processing | Advanced processing with microcontrollers and software |

| Cost | Generally lower initial cost | Higher initial cost but lower lifecycle cost |

| Durability | Susceptible to mechanical wear | Robust with solid-state components |

| Output | Analog meters, chart recorders | Digital displays, computer interfaces |

Introduction to Analog and Digital Instrumentation

Analog instrumentation measures continuous signals through physical means such as voltage or current variations, providing real-time data that reflects gradual changes in equipment performance. Digital instrumentation converts analog signals into discrete numerical values using analog-to-digital converters, enabling precise data analysis, storage, and remote monitoring. Modern equipment increasingly integrates digital instrumentation for enhanced accuracy, programmability, and connectivity in industrial applications.

Key Differences Between Analog and Digital Instruments

Analog instrumentation processes continuous signals, providing real-time and smooth variations in measurement, while digital instrumentation converts analog signals into discrete numerical data for precise analysis and storage. Analog instruments offer simplicity and immediacy but are prone to noise and signal degradation, whereas digital instruments enhance accuracy, data manipulation, and integration with computer systems. Key differences also include calibration complexity, signal resolution, response time, and compatibility with automated control systems, making digital instruments preferable for modern, high-precision applications.

Accuracy and Precision: Analog vs Digital Measurements

Digital instrumentation provides higher accuracy and precision due to its ability to minimize signal noise and enable easy calibration, offering consistent and repeatable measurements. Analog instrumentation may exhibit signal drift and susceptibility to external interferences, which can reduce measurement reliability over time. Digital sensors typically feature resolution levels down to micro or nano units, enhancing measurement fidelity compared to the continuous yet less precise readings of analog devices.

Signal Processing Capabilities in Analog and Digital Devices

Analog instrumentation processes continuous signals, providing real-time monitoring with minimal latency but limited flexibility in signal manipulation. Digital instrumentation converts analog inputs into discrete digital signals, enabling advanced signal processing techniques such as filtering, averaging, and complex mathematical computations. Enhanced noise rejection and data storage capabilities make digital devices superior for precise and customizable signal analysis in modern equipment.

Cost Comparison: Analog vs Digital Instrumentation

Analog instrumentation typically incurs lower initial costs due to simpler technology and fewer components, making it cost-effective for basic measurement tasks. Digital instrumentation, while often more expensive upfront, offers long-term savings through enhanced accuracy, easier calibration, and reduced maintenance expenses. The total cost of ownership favors digital systems in complex applications where precision and data integration significantly improve operational efficiency.

Ease of Use and User Interface

Analog instrumentation offers simplicity with intuitive dials and gauges, allowing users to quickly interpret measurements without extensive training. Digital instrumentation provides advanced user interfaces featuring touchscreens, customizable displays, and data logging, enhancing precision and accessibility for complex monitoring tasks. The combination of clear visualization and interactive controls in digital instruments significantly improves ease of use in modern equipment applications.

Maintenance and Calibration Requirements

Analog instrumentation requires frequent manual calibration and routine maintenance due to signal drift and component aging, which can lead to decreased accuracy over time. Digital instrumentation offers enhanced stability and often includes self-calibration features, reducing the need for frequent maintenance and improving long-term reliability. Maintenance costs are generally lower with digital systems, and calibration procedures can be automated and integrated into software for precision and efficiency.

Applications Suited for Analog vs Digital Instrumentation

Analog instrumentation excels in applications requiring real-time monitoring of continuous signals, such as temperature, pressure, and flow measurement in industrial processes. Digital instrumentation is preferred for complex data analysis, remote monitoring, and integration with automation systems in manufacturing and process control. Analog systems are often chosen for their simplicity and reliability in harsh environments, while digital instruments offer enhanced accuracy, programmability, and data storage capabilities.

Integration with Modern Systems and Data Logging

Digital instrumentation offers superior integration with modern systems through standardized communication protocols such as Modbus, Ethernet/IP, and OPC-UA, enabling seamless data exchange and remote monitoring capabilities. Analog instrumentation requires additional interfaces or converters to connect with digital systems, often complicating data logging processes. Advanced digital instruments inherently support automated data logging, real-time analytics, and cloud connectivity, enhancing operational efficiency and predictive maintenance.

Future Trends in Instrumentation Technology

Future trends in instrumentation technology emphasize the integration of digital instrumentation due to its superior accuracy, real-time data processing, and ease of remote monitoring compared to analog systems. Advanced digital sensors and IoT-enabled devices facilitate predictive maintenance and enhanced system diagnostics, driving industry 4.0 innovation. Continuous improvements in AI-driven analytics and cloud integration further propel the shift from analog to digital instrumentation, optimizing operational efficiency and decision-making.

Analog instrumentation vs digital instrumentation Infographic

productdif.com

productdif.com