Batch testing involves analyzing samples at scheduled intervals to assess equipment performance, providing detailed but periodic insights. Continuous monitoring employs real-time data collection to detect anomalies instantly, enhancing proactive maintenance and reducing downtime. Choosing between batch testing and continuous monitoring depends on factors like equipment criticality, cost considerations, and the need for immediate response.

Table of Comparison

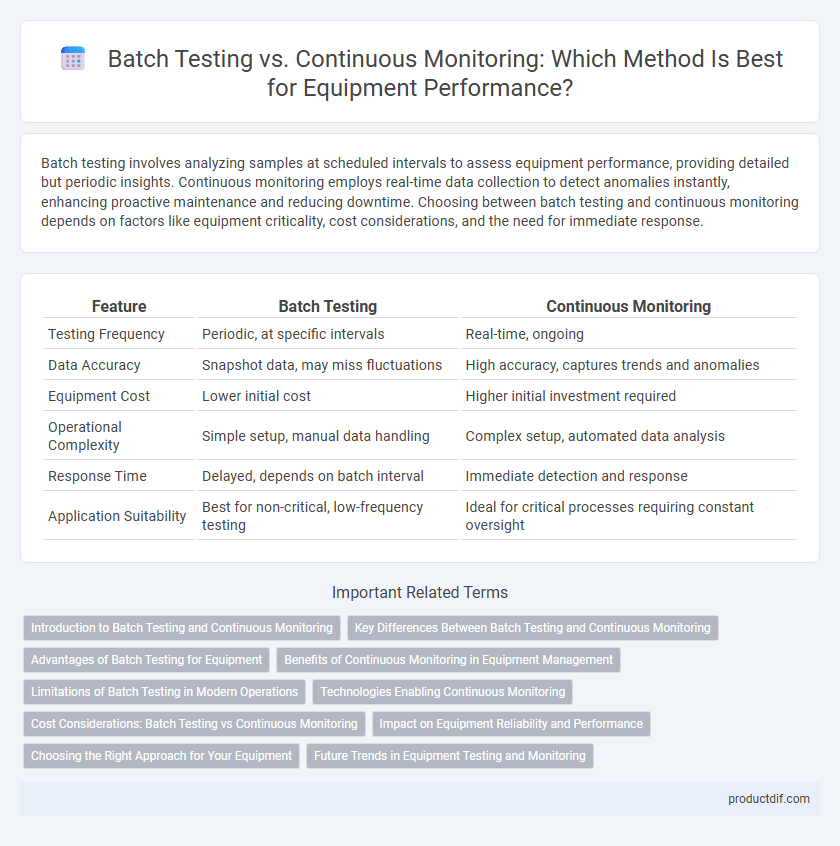

| Feature | Batch Testing | Continuous Monitoring |

|---|---|---|

| Testing Frequency | Periodic, at specific intervals | Real-time, ongoing |

| Data Accuracy | Snapshot data, may miss fluctuations | High accuracy, captures trends and anomalies |

| Equipment Cost | Lower initial cost | Higher initial investment required |

| Operational Complexity | Simple setup, manual data handling | Complex setup, automated data analysis |

| Response Time | Delayed, depends on batch interval | Immediate detection and response |

| Application Suitability | Best for non-critical, low-frequency testing | Ideal for critical processes requiring constant oversight |

Introduction to Batch Testing and Continuous Monitoring

Batch testing involves analyzing samples collected at specific intervals to identify equipment performance or product quality variations, providing detailed data for periodic assessment. Continuous monitoring uses real-time sensors and automated systems to track equipment parameters continuously, enabling immediate detection of anomalies and ongoing process optimization. Both methods are crucial in equipment maintenance and quality control, with batch testing offering in-depth periodic insights and continuous monitoring ensuring constant oversight.

Key Differences Between Batch Testing and Continuous Monitoring

Batch testing analyzes multiple samples collected over a specific period to identify equipment performance or quality issues at set intervals, providing periodic insights but potentially missing real-time fluctuations. Continuous monitoring utilizes real-time data acquisition from sensors on equipment, enabling immediate detection of anomalies and ongoing performance evaluation for proactive maintenance. Key differences lie in frequency, data immediacy, and responsiveness, as batch testing offers delayed results based on sample analysis, whereas continuous monitoring delivers constant updates for instant decision-making.

Advantages of Batch Testing for Equipment

Batch testing offers precise control over equipment quality by isolating specific production runs, enabling detailed inspection and targeted troubleshooting. This method reduces the risk of widespread defects by identifying issues at discrete intervals rather than relying on ongoing data streams. Batch testing also simplifies documentation and compliance verification, providing clear records for regulatory audits and quality assurance.

Benefits of Continuous Monitoring in Equipment Management

Continuous monitoring in equipment management offers real-time data collection and analysis, enabling immediate detection of faults and performance deviations. This proactive approach significantly reduces downtime and maintenance costs by allowing timely interventions before failures occur. Continuous monitoring also enhances asset lifespan and operational efficiency through consistent condition assessment and automated alerts.

Limitations of Batch Testing in Modern Operations

Batch testing often results in time delays and lacks real-time data, hindering swift decision-making in modern operations. The discrete nature of batch testing can cause missed anomalies and inconsistencies during the production process. Limited sensitivity to process fluctuations reduces its effectiveness compared to continuous monitoring systems.

Technologies Enabling Continuous Monitoring

Continuous monitoring leverages advanced sensor technologies, IoT connectivity, and real-time data analytics to provide uninterrupted equipment performance insights. Machine learning algorithms enhance predictive maintenance by identifying anomalies faster than traditional batch testing. Integration of cloud platforms enables scalable data storage and remote monitoring, optimizing operational efficiency and reducing downtime.

Cost Considerations: Batch Testing vs Continuous Monitoring

Batch testing often involves lower upfront costs due to periodic sampling and analysis, making it suitable for smaller-scale operations with limited budgets. Continuous monitoring requires higher initial investment in advanced sensors and automation but reduces long-term expenses by enabling real-time data collection and early detection of issues, minimizing downtime and maintenance costs. Overall, the choice between batch testing and continuous monitoring hinges on balancing capital expenditure against operational efficiency and potential cost savings over time.

Impact on Equipment Reliability and Performance

Batch testing provides periodic insights into equipment condition, identifying issues during scheduled intervals that may delay detection of emerging faults. Continuous monitoring delivers real-time data, enabling immediate response to performance anomalies, which significantly enhances equipment reliability by preventing unplanned downtime. Implementing continuous monitoring optimizes maintenance schedules and extends equipment lifespan by maintaining consistent operational performance.

Choosing the Right Approach for Your Equipment

Batch testing provides precise snapshots of equipment performance by analyzing data at set intervals, ideal for thorough inspections or quality control. Continuous monitoring offers real-time data collection, enabling instant detection of anomalies and predictive maintenance for critical machinery. Selecting the right approach depends on factors such as equipment complexity, operational criticality, and the need for timely intervention to minimize downtime.

Future Trends in Equipment Testing and Monitoring

Future trends in equipment testing emphasize the integration of advanced sensors and IoT technology to enable continuous monitoring, allowing real-time data collection and predictive maintenance. Batch testing remains relevant for validating new equipment performance, but the shift towards automated, AI-driven analytics enhances fault detection and operational efficiency. Emerging technologies like machine learning algorithms and edge computing will further refine equipment health assessments, reducing downtime and extending asset lifespan.

Batch testing vs Continuous monitoring Infographic

productdif.com

productdif.com