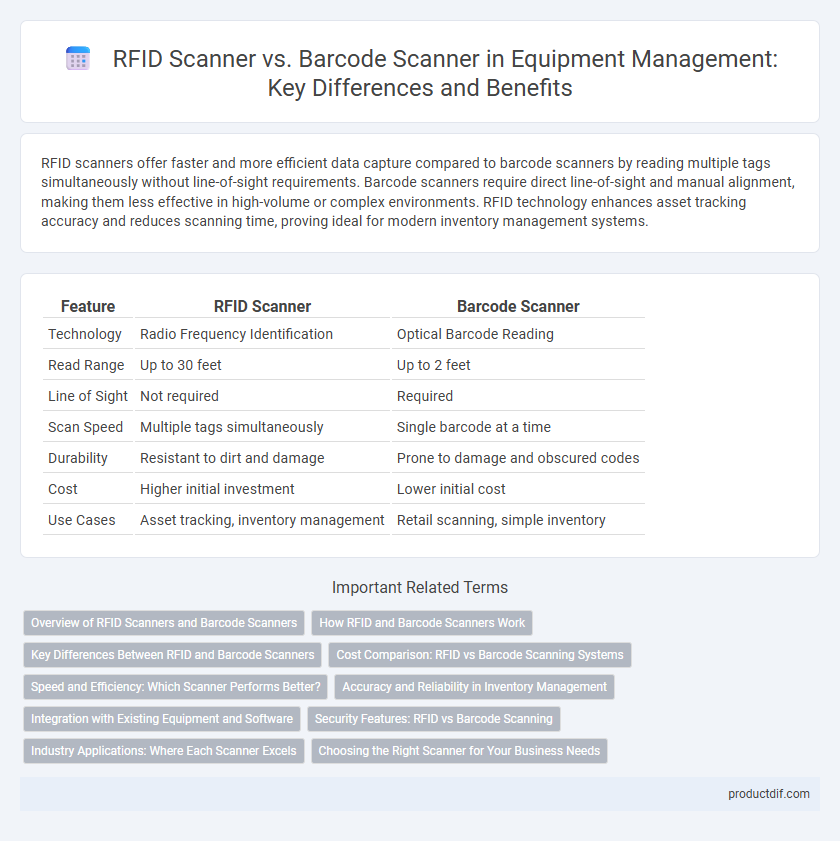

RFID scanners offer faster and more efficient data capture compared to barcode scanners by reading multiple tags simultaneously without line-of-sight requirements. Barcode scanners require direct line-of-sight and manual alignment, making them less effective in high-volume or complex environments. RFID technology enhances asset tracking accuracy and reduces scanning time, proving ideal for modern inventory management systems.

Table of Comparison

| Feature | RFID Scanner | Barcode Scanner |

|---|---|---|

| Technology | Radio Frequency Identification | Optical Barcode Reading |

| Read Range | Up to 30 feet | Up to 2 feet |

| Line of Sight | Not required | Required |

| Scan Speed | Multiple tags simultaneously | Single barcode at a time |

| Durability | Resistant to dirt and damage | Prone to damage and obscured codes |

| Cost | Higher initial investment | Lower initial cost |

| Use Cases | Asset tracking, inventory management | Retail scanning, simple inventory |

Overview of RFID Scanners and Barcode Scanners

RFID scanners utilize radio waves to identify and track tags attached to objects, offering fast, contactless scanning with the ability to read multiple items simultaneously, which enhances inventory management efficiency. Barcode scanners rely on optical technology to read printed barcodes, requiring direct line-of-sight and typically scanning one item at a time, making them suitable for straightforward, cost-effective identification tasks. Both technologies serve distinct needs in logistics and retail, with RFID providing greater automation capabilities and barcode systems favoring simplicity and widespread adoption.

How RFID and Barcode Scanners Work

RFID scanners use radio waves to automatically identify and track tags attached to objects, enabling contactless data capture from multiple items simultaneously. Barcode scanners rely on laser or camera-based technology to read black-and-white patterns, decoding the barcode's information linearly with a direct line of sight. RFID technology offers faster scanning speeds and can operate in various environmental conditions, while barcode scanners require precise alignment and are generally limited to single-item scanning.

Key Differences Between RFID and Barcode Scanners

RFID scanners use radio frequency waves to read tags wirelessly, allowing multiple items to be scanned simultaneously without direct line-of-sight, while barcode scanners require visual alignment with the barcode for each item. RFID tags offer faster data capture and enhanced durability under harsh conditions compared to the paper or sticker-based barcodes, which can be damaged easily. Cost-wise, RFID systems generally involve higher upfront investment but provide long-term efficiency in inventory management and asset tracking over barcode systems.

Cost Comparison: RFID vs Barcode Scanning Systems

RFID scanning systems generally have higher initial costs due to the price of RFID tags and readers, which can range from $200 to $500 per reader, compared to barcode scanners that often cost between $50 and $300. Barcode systems benefit from cheaper tags and widespread compatibility, with labels costing mere cents, while RFID tags can cost from $0.10 to $5 or more depending on type and durability. Despite higher upfront expenses, RFID systems offer long-term savings through improved inventory accuracy and faster scanning speeds, potentially reducing labor costs by up to 30% in some warehouse operations.

Speed and Efficiency: Which Scanner Performs Better?

RFID scanners significantly outperform barcode scanners in speed and efficiency by enabling rapid, simultaneous reading of multiple tags without direct line-of-sight, eliminating the need to individually scan each item. Barcode scanners require precise alignment and are limited to scanning one code at a time, resulting in slower inventory processing and higher labor costs. In environments demanding quick asset tracking and high throughput, RFID technology provides superior performance through streamlined data capture and reduced scanning errors.

Accuracy and Reliability in Inventory Management

RFID scanners offer superior accuracy and reliability in inventory management by enabling non-line-of-sight scanning and simultaneous reading of multiple tags, reducing human error significantly compared to barcode scanners. Barcode scanners require direct line-of-sight and single-item scanning, which increases the risk of missed or misread items during fast-paced inventory processes. The advanced sensor technology in RFID systems enhances real-time data accuracy, leading to improved stock visibility and more efficient supply chain operations.

Integration with Existing Equipment and Software

RFID scanners seamlessly integrate with existing equipment and software through middleware that connects RFID data to enterprise systems like ERP and WMS, enabling real-time inventory tracking and automated data capture. Barcode scanners rely on standard APIs and USB or Bluetooth interfaces for easy connection to existing software platforms, but require line-of-sight scanning and manual data entry points. RFID technology offers superior compatibility with automated systems for high-volume environments, while barcode scanners remain cost-effective for straightforward integration with legacy software.

Security Features: RFID vs Barcode Scanning

RFID scanners offer enhanced security features such as encrypted data transmission and unique tag identifiers that minimize the risk of cloning and unauthorized access. Barcode scanners rely on visible codes that can be easily duplicated or manipulated, making them less secure for sensitive applications. The advanced authentication protocols in RFID technology provide superior protection against data breaches and counterfeiting compared to traditional barcode scanning.

Industry Applications: Where Each Scanner Excels

RFID scanners excel in inventory management and asset tracking within large warehouses and manufacturing plants due to their ability to read multiple tags simultaneously without line-of-sight. Barcode scanners are highly effective in retail checkout systems and small-scale logistics where quick, accurate item identification is needed and cost efficiency is crucial. Industries such as pharmaceuticals and automotive benefit from RFID's enhanced data capture and security, while grocery stores and libraries often rely on barcode technology for its simplicity and widespread adoption.

Choosing the Right Scanner for Your Business Needs

RFID scanners provide faster, contactless data capture and can read multiple tags simultaneously, making them ideal for inventory management and asset tracking in large warehouses. Barcode scanners offer cost-effective, precise scanning for retail environments where individual item identification is critical. Evaluating factors such as scanning speed, range, accuracy, and budget helps businesses select the optimal scanner to improve operational efficiency.

RFID scanner vs Barcode scanner Infographic

productdif.com

productdif.com