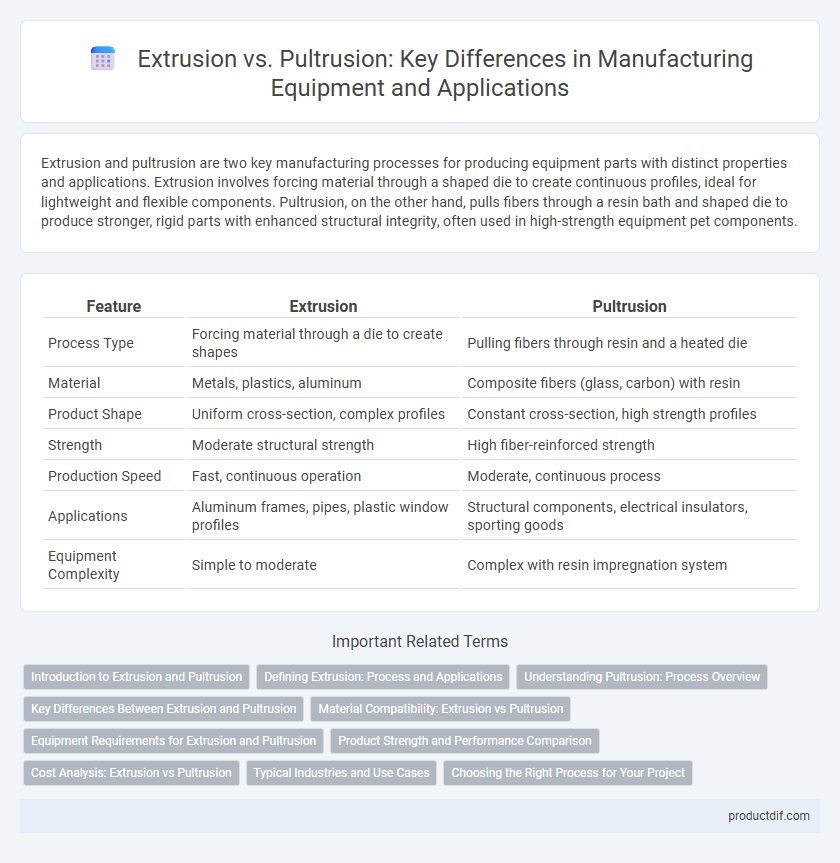

Extrusion and pultrusion are two key manufacturing processes for producing equipment parts with distinct properties and applications. Extrusion involves forcing material through a shaped die to create continuous profiles, ideal for lightweight and flexible components. Pultrusion, on the other hand, pulls fibers through a resin bath and shaped die to produce stronger, rigid parts with enhanced structural integrity, often used in high-strength equipment pet components.

Table of Comparison

| Feature | Extrusion | Pultrusion |

|---|---|---|

| Process Type | Forcing material through a die to create shapes | Pulling fibers through resin and a heated die |

| Material | Metals, plastics, aluminum | Composite fibers (glass, carbon) with resin |

| Product Shape | Uniform cross-section, complex profiles | Constant cross-section, high strength profiles |

| Strength | Moderate structural strength | High fiber-reinforced strength |

| Production Speed | Fast, continuous operation | Moderate, continuous process |

| Applications | Aluminum frames, pipes, plastic window profiles | Structural components, electrical insulators, sporting goods |

| Equipment Complexity | Simple to moderate | Complex with resin impregnation system |

Introduction to Extrusion and Pultrusion

Extrusion is a manufacturing process that forces material through a shaped die to create continuous profiles with uniform cross-sections, commonly used for metals, plastics, and composites. Pultrusion involves pulling fibers through a resin bath and shaping them via a heated die, producing strong, lightweight composite profiles with consistent cross-sectional shapes. Both processes are essential in equipment fabrication, offering distinct advantages in material properties and production efficiency for specialized industrial applications.

Defining Extrusion: Process and Applications

Extrusion is a manufacturing process that involves forcing molten or pliable material through a die to create objects with a fixed cross-sectional profile, commonly used for producing pipes, sheets, and complex shapes from metals, plastics, and composites. This process offers precise control over dimensions and surface finish, making it ideal for applications in automotive, construction, and packaging industries. Unlike pultrusion, extrusion handles a wider variety of materials and shapes, supporting high-volume production with consistent quality.

Understanding Pultrusion: Process Overview

Pultrusion is a continuous manufacturing process that involves pulling reinforced fibers through a resin bath and then through a heated die to cure the composite into a constant cross-sectional shape. This technique is ideal for producing high-strength, lightweight components such as beams, rods, and channels used in construction and industrial applications. Pultruded products offer superior mechanical properties, corrosion resistance, and design flexibility compared to traditional materials.

Key Differences Between Extrusion and Pultrusion

Extrusion involves forcing heated material through a shaped die to create continuous profiles, primarily using metals and plastics, while pultrusion pulls fibers through resin and a heated die to form composite materials with consistent cross-sections. Extrusion offers versatility in shape complexity and thickness variation, whereas pultrusion produces high-strength, lightweight components with fiber alignment enhancing mechanical properties. The primary difference lies in material state and reinforcement methods, impacting applications in automotive, aerospace, and construction industries.

Material Compatibility: Extrusion vs Pultrusion

Extrusion excels in processing thermoplastics such as polyethylene, polypropylene, and PVC, offering flexibility in shape and complexity for various industrial applications. Pultrusion is tailored for continuous fiber-reinforced composites like fiberglass and carbon fiber, providing superior strength-to-weight ratios and dimensional stability. Material compatibility dictates that extrusion suits homogenous polymers, while pultrusion is ideal for anisotropic composite materials requiring enhanced mechanical properties.

Equipment Requirements for Extrusion and Pultrusion

Extrusion equipment requires high-pressure hydraulic systems and heated barrels to melt and force thermoplastic or metal materials through precise dies, whereas pultrusion equipment relies on a continuous pulling mechanism combined with heated dies to shape and cure reinforced composites. Extrusion machines demand robust screw designs and temperature controls to ensure material homogeneity, while pultrusion systems focus on tension control and resin impregnation units for fiber reinforcement. Both processes necessitate automation systems for consistent production but differ significantly in thermal management and mechanical force applications.

Product Strength and Performance Comparison

Extrusion produces products with uniform cross-sections and good dimensional accuracy, while pultrusion yields components with superior fiber alignment, resulting in enhanced tensile strength and improved impact resistance. Pultruded materials typically exhibit higher mechanical performance under stress due to continuous fiber reinforcement, offering better durability in structural applications compared to extruded counterparts. The controlled fiber orientation in pultrusion optimizes load-bearing capacity, making it ideal for high-strength composite profiles.

Cost Analysis: Extrusion vs Pultrusion

Extrusion typically incurs lower initial equipment costs compared to pultrusion, making it more cost-effective for high-volume production of uniform profiles. Pultrusion, while offering higher strength-to-weight ratios and superior structural properties, involves higher setup and tooling expenses, impacting upfront investment. Operational costs in pultrusion can be offset by reduced material waste and energy efficiency, whereas extrusion benefits from faster cycle times that lower labor costs.

Typical Industries and Use Cases

Extrusion is widely used in automotive, packaging, and construction industries for producing continuous profiles like pipes, tubing, and window frames from materials such as aluminum and plastics. Pultrusion is favored in aerospace, electrical, and marine sectors for manufacturing composite components like reinforced panels, structural beams, and insulating rods with consistent cross-sections. Both processes enable high-volume production, but extrusion excels in shaping metals and thermoplastics, while pultrusion is specialized in producing fiber-reinforced polymer parts.

Choosing the Right Process for Your Project

Extrusion excels in producing complex cross-sections from thermoplastic or metal materials with high precision and scalability, making it ideal for projects requiring intricate shapes and flexible material choices. Pultrusion delivers superior strength and fiber alignment in composite materials, particularly for applications demanding high structural integrity and consistent fiber reinforcement. Selecting the right process depends on project-specific criteria such as material type, desired mechanical properties, production volume, and shape complexity.

Extrusion vs Pultrusion Infographic

productdif.com

productdif.com