Single-use equipment offers superior sterility and reduces the risk of cross-contamination, making it ideal for applications requiring strict hygiene standards. Reusable equipment provides cost efficiency and sustainability by allowing multiple sterilization cycles, but it requires rigorous maintenance protocols to prevent infection. Selecting between single-use and reusable equipment depends on balancing safety, budget, and environmental impact in healthcare and industrial settings.

Table of Comparison

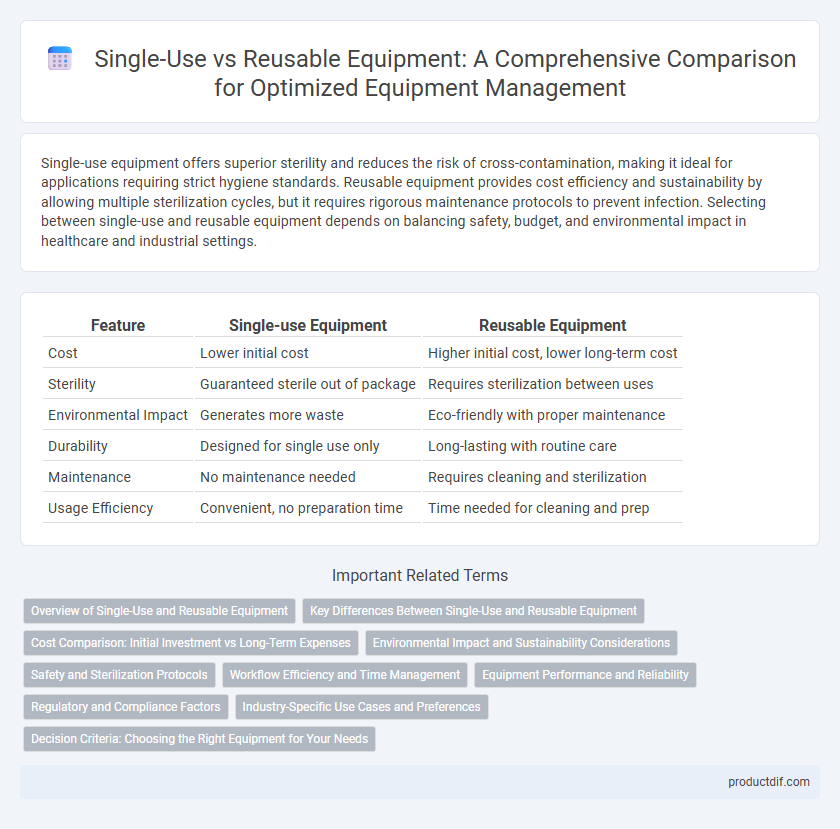

| Feature | Single-use Equipment | Reusable Equipment |

|---|---|---|

| Cost | Lower initial cost | Higher initial cost, lower long-term cost |

| Sterility | Guaranteed sterile out of package | Requires sterilization between uses |

| Environmental Impact | Generates more waste | Eco-friendly with proper maintenance |

| Durability | Designed for single use only | Long-lasting with routine care |

| Maintenance | No maintenance needed | Requires cleaning and sterilization |

| Usage Efficiency | Convenient, no preparation time | Time needed for cleaning and prep |

Overview of Single-Use and Reusable Equipment

Single-use equipment is designed for one-time use, offering advantages such as reduced risk of cross-contamination and lower initial sterilization costs. Reusable equipment, made from durable materials like stainless steel or high-grade plastic, supports long-term usage but requires stringent cleaning and sterilization protocols to ensure safety. Industries like pharmaceuticals and healthcare often balance the choice between single-use and reusable equipment based on factors including cost-efficiency, environmental impact, and regulatory compliance.

Key Differences Between Single-Use and Reusable Equipment

Single-use equipment is designed for one-time usage, eliminating the need for cleaning and reducing contamination risks, whereas reusable equipment requires thorough sterilization after each use to ensure safety. Single-use options typically offer cost savings in terms of labor and sterilization but generate more waste compared to reusable equipment, which has higher upfront costs but lower long-term expenses. The choice between single-use and reusable equipment depends on factors such as infection control protocols, operational costs, and environmental impact priorities.

Cost Comparison: Initial Investment vs Long-Term Expenses

Single-use equipment requires a lower initial investment but incurs continuous replacement costs that can accumulate significantly over time. Reusable equipment demands higher upfront expenses due to durable materials and design but offers cost savings through repeated use and lower per-cycle costs. Factoring in maintenance, sterilization, and potential downtime is crucial for an accurate long-term expense comparison between the two options.

Environmental Impact and Sustainability Considerations

Single-use equipment generates significant plastic waste, contributing to landfill overflow and environmental pollution, while reusable equipment reduces waste by enabling multiple sterilizations and extended use cycles. Lifecycle assessments reveal that although reusable equipment requires energy and water for cleaning and sterilization, its overall carbon footprint and resource consumption are lower than single-use alternatives. Sustainable practices prioritize reusable equipment to minimize environmental impact, conserve resources, and support circular economy principles in healthcare and industrial settings.

Safety and Sterilization Protocols

Single-use equipment eliminates the risk of cross-contamination by being disposed of after one use, ensuring the highest safety standards in sterile environments. Reusable equipment requires stringent sterilization protocols, including autoclaving and chemical disinfection, to effectively remove pathogens and prevent infections. Rigorous adherence to validated sterilization cycles and regular maintenance is critical to maintaining the integrity and safety of reusable medical devices.

Workflow Efficiency and Time Management

Single-use equipment reduces cleaning and sterilization time, streamlining workflow efficiency by minimizing downtime between procedures. Reusable equipment requires thorough decontamination and maintenance, potentially extending turnaround times but offering cost savings over time. Optimizing time management involves balancing the immediacy of single-use disposables with the durability and long-term availability of reusable tools.

Equipment Performance and Reliability

Single-use equipment delivers consistent performance by eliminating cross-contamination risks and reducing maintenance downtime, ensuring reliable output in critical processes. Reusable equipment offers long-term cost savings and robustness but requires rigorous cleaning and validation protocols to maintain performance standards and prevent reliability issues. Equipment performance and reliability heavily depend on the specific application, with single-use systems favored in sterile or sensitive environments while reusable systems excel in high-volume operations requiring durability.

Regulatory and Compliance Factors

Regulatory bodies such as the FDA and EMA impose strict guidelines on single-use equipment to prevent cross-contamination and ensure sterility, often requiring validation and documentation for disposal processes. Reusable equipment mandates rigorous cleaning, sterilization protocols, and routine inspections compliant with ISO 13485 and GMP standards to maintain traceability and avoid microbial contamination. Compliance audits emphasize risk assessment and lifecycle management, influencing validation costs and operational efficiency in manufacturing environments.

Industry-Specific Use Cases and Preferences

Single-use equipment is preferred in the pharmaceutical and biotech industries for maintaining sterility and reducing contamination risk, especially in aseptic processing and cell culture applications. Reusable equipment remains common in heavy manufacturing and food production due to cost efficiency and durability, with strict cleaning protocols ensuring compliance with safety standards. Industry-specific regulations and product sensitivity heavily influence the choice between single-use and reusable equipment in diverse operational environments.

Decision Criteria: Choosing the Right Equipment for Your Needs

Selecting between single-use equipment and reusable equipment depends heavily on factors such as cost efficiency, operational scale, and contamination risk. Single-use equipment offers advantages in minimizing cross-contamination and reducing cleaning validation time, making it suitable for small-batch or highly sensitive applications. Reusable equipment, while requiring higher upfront investment and maintenance, delivers cost savings over long-term use and is ideal for large-scale production environments.

Single-use equipment vs Reusable equipment Infographic

productdif.com

productdif.com