Primary equipment in pet care includes essential items directly supporting pets' health and daily needs, such as collars, leashes, and feeding bowls. Secondary equipment encompasses supplementary items like grooming tools, toys, and travel accessories that enhance comfort and engagement. Understanding the distinction helps pet owners prioritize investments for optimal pet well-being and convenience.

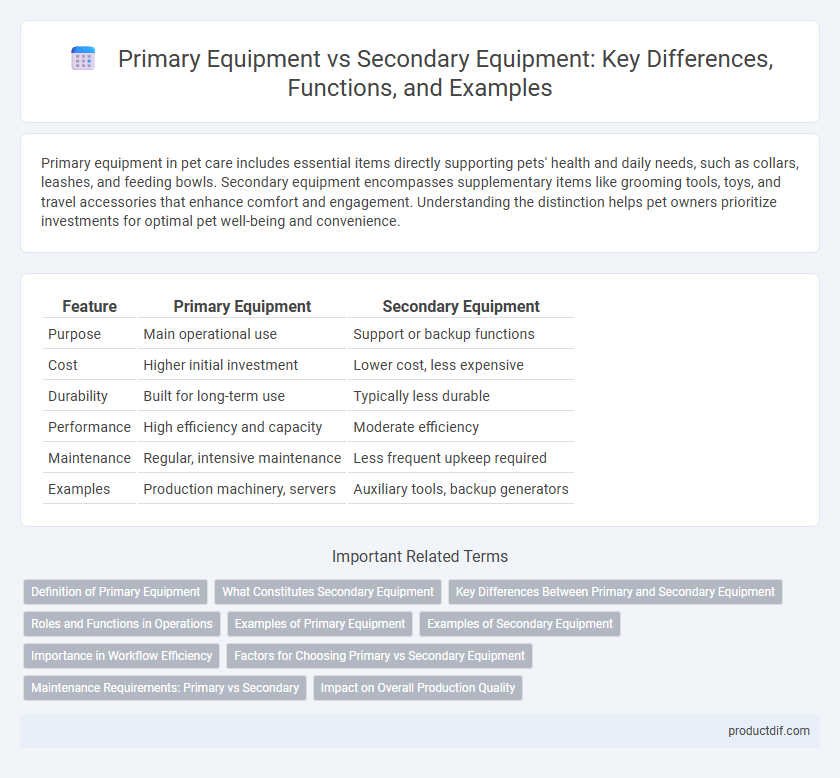

Table of Comparison

| Feature | Primary Equipment | Secondary Equipment |

|---|---|---|

| Purpose | Main operational use | Support or backup functions |

| Cost | Higher initial investment | Lower cost, less expensive |

| Durability | Built for long-term use | Typically less durable |

| Performance | High efficiency and capacity | Moderate efficiency |

| Maintenance | Regular, intensive maintenance | Less frequent upkeep required |

| Examples | Production machinery, servers | Auxiliary tools, backup generators |

Definition of Primary Equipment

Primary equipment refers to the essential machinery or devices directly involved in the core processes of an operation, such as turbines in power plants or compressors in gas processing. These components perform the main functions that define the system's purpose and are critical for overall performance and efficiency. Primary equipment is distinguished by its direct interaction with the primary product or process stream, unlike secondary equipment that supports or enhances the primary systems.

What Constitutes Secondary Equipment

Secondary equipment refers to auxiliary devices that support the primary equipment's operation without performing its core functions. These include control panels, sensors, relays, and monitoring instruments that facilitate the efficient management and safety of primary machinery. Secondary equipment enhances overall system performance by providing data acquisition, diagnostics, and control capabilities essential for maintaining optimal operation.

Key Differences Between Primary and Secondary Equipment

Primary equipment refers to the main machinery or devices directly involved in production or operation processes, such as turbines, pumps, and compressors. Secondary equipment supports the primary systems by providing auxiliary functions like cooling, lubrication, or control, including heat exchangers, filters, and instrumentation panels. The key differences lie in their roles and criticality: primary equipment drives the core function, while secondary equipment ensures optimal performance and safety.

Roles and Functions in Operations

Primary equipment serves as the main tools or machines directly involved in the core production or operational processes, such as conveyor belts in manufacturing or servers in IT infrastructure. Secondary equipment supports and enhances the functionality of primary equipment by providing necessary ancillary services like cooling systems, backup power supplies, or maintenance tools. Understanding the roles and functions of both types ensures efficient workflow, minimizes downtime, and optimizes overall operational performance.

Examples of Primary Equipment

Primary equipment in manufacturing and industrial settings includes essential machines such as lathes, milling machines, presses, and injection molding machines that directly shape, form, or assemble raw materials. These machines perform core production tasks and are critical to the operational workflow, ensuring product quality and efficiency. Unlike secondary equipment, which supports or enhances the primary processes, primary equipment directly impacts the main manufacturing phase.

Examples of Secondary Equipment

Secondary equipment in industrial and manufacturing settings includes items such as pumps, compressors, valves, heat exchangers, and instrumentation devices that support the operation of primary equipment like reactors or turbines. These components play a crucial role in maintaining system efficiency, safety, and control by facilitating fluid transfer, pressure regulation, and temperature monitoring. Examples of secondary equipment also encompass cooling towers, filters, and control panels essential for optimal process management and equipment longevity.

Importance in Workflow Efficiency

Primary equipment such as main machinery directly impacts workflow efficiency by enabling core processes and maintaining production speed. Secondary equipment supports primary systems by ensuring safety, quality control, and minimizing downtime, which collectively enhances operational continuity. Optimizing the use of both equipment types reduces bottlenecks and maximizes overall productivity.

Factors for Choosing Primary vs Secondary Equipment

Key factors for choosing primary versus secondary equipment include operational criticality, cost-effectiveness, and maintenance requirements. Primary equipment must ensure high reliability and performance due to its essential role in core processes, while secondary equipment is selected based on flexibility, backup capabilities, and lower operational risks. Environmental conditions and compatibility with existing systems also influence the decision-making process between primary and secondary equipment.

Maintenance Requirements: Primary vs Secondary

Primary equipment demands rigorous, frequent maintenance due to its critical role and direct impact on operational efficiency, often requiring specialized technicians and scheduled downtime. Secondary equipment typically involves less intensive maintenance, focusing on routine inspections and minor repairs to support primary systems without causing major disruptions. Understanding the distinct maintenance requirements of primary versus secondary equipment helps optimize resource allocation and minimize system failures.

Impact on Overall Production Quality

Primary equipment directly influences overall production quality by ensuring core processes meet precise standards, while secondary equipment supports auxiliary functions that enhance operational efficiency and maintain consistency. High-performance primary equipment reduces defects and variability, leading to superior product reliability and customer satisfaction. Optimizing secondary equipment minimizes downtime and contamination risks, indirectly improving the final product's quality and throughput.

Primary Equipment vs Secondary Equipment Infographic

productdif.com

productdif.com