AC drives offer greater energy efficiency and lower maintenance costs compared to DC drives due to their simpler construction and use of inverter technology. DC drives provide excellent torque control and faster acceleration, making them ideal for applications requiring precise speed regulation. Selection between AC and DC drives depends on the specific operational requirements, such as load characteristics and control complexity.

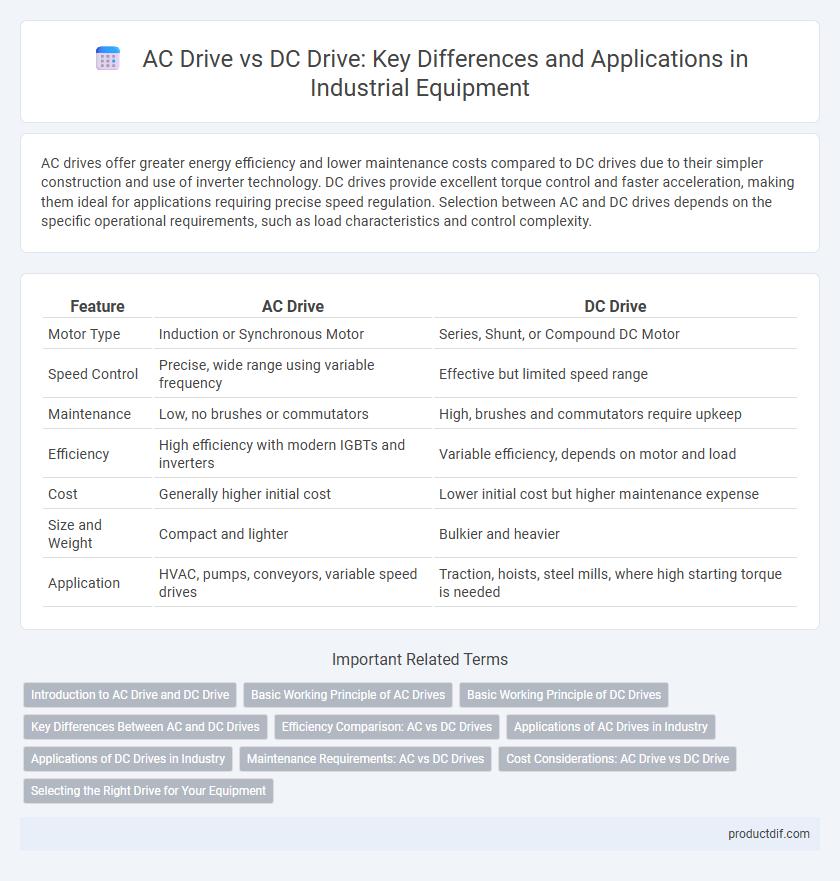

Table of Comparison

| Feature | AC Drive | DC Drive |

|---|---|---|

| Motor Type | Induction or Synchronous Motor | Series, Shunt, or Compound DC Motor |

| Speed Control | Precise, wide range using variable frequency | Effective but limited speed range |

| Maintenance | Low, no brushes or commutators | High, brushes and commutators require upkeep |

| Efficiency | High efficiency with modern IGBTs and inverters | Variable efficiency, depends on motor and load |

| Cost | Generally higher initial cost | Lower initial cost but higher maintenance expense |

| Size and Weight | Compact and lighter | Bulkier and heavier |

| Application | HVAC, pumps, conveyors, variable speed drives | Traction, hoists, steel mills, where high starting torque is needed |

Introduction to AC Drive and DC Drive

AC drives control the speed and torque of alternating current motors by varying frequency and voltage, offering energy efficiency and precise motor management in industrial applications. DC drives regulate the speed of direct current motors through voltage adjustments to the armature or field, providing excellent speed control and high starting torque. Both AC and DC drives are essential in equipment automation, with AC drives favored for their reduced maintenance and longer lifespan compared to DC counterparts.

Basic Working Principle of AC Drives

AC drives operate by converting incoming AC power to DC through a rectifier, then modulating the DC voltage and frequency using an inverter to control motor speed and torque precisely. This ability to vary frequency allows AC motors to run efficiently over a wide range of speeds, unlike DC drives that rely on varying armature voltage. The use of Pulse Width Modulation (PWM) in AC drives ensures smooth and energy-efficient motor performance with reduced maintenance needs.

Basic Working Principle of DC Drives

DC drives operate by regulating the voltage supplied to the DC motor, controlling the armature current to adjust motor speed and torque precisely. The basic working principle involves converting AC supply to DC using a rectifier, followed by varying the output voltage through semiconductor devices like thyristors or transistors. This voltage control directly influences the motor's rotational speed and load handling capabilities, making DC drives suitable for applications requiring fine speed regulation and high starting torque.

Key Differences Between AC and DC Drives

AC drives use alternating current and typically employ variable frequency control for speed regulation, making them highly efficient and suitable for a wide range of industrial applications. DC drives rely on direct current and offer excellent torque control at low speeds, ideal for applications requiring precise speed and position control. The choice between AC and DC drives depends on factors such as motor type, control complexity, maintenance requirements, and application-specific torque and speed needs.

Efficiency Comparison: AC vs DC Drives

AC drives generally offer higher energy efficiency compared to DC drives due to their ability to precisely control motor speed and reduce power losses in variable load conditions. Advanced AC inverter technology enables smoother acceleration and deceleration, minimizing wasted energy during operation. DC drives often have lower initial costs but tend to consume more energy and require more maintenance due to brush and commutator wear, impacting overall efficiency over time.

Applications of AC Drives in Industry

AC drives are extensively used in industries such as HVAC, conveyors, pumps, and fans for precise speed and torque control. Their ability to improve energy efficiency and reduce maintenance costs makes them ideal for applications requiring variable speed operation. Industries like manufacturing, mining, and water treatment benefit from AC drives' robustness and scalability in automated process control.

Applications of DC Drives in Industry

DC drives are extensively utilized in industries requiring precise speed control and high starting torque, such as steel mills, paper manufacturing, and elevators. Their ability to maintain consistent performance under varying load conditions makes them ideal for heavy-duty applications like rolling mills and cranes. Unlike AC drives, DC drives offer superior speed regulation and dynamic response in processes demanding fine-tuned motor control.

Maintenance Requirements: AC vs DC Drives

AC drives require less frequent maintenance due to their solid-state components and absence of brushes, reducing wear and tear compared to DC drives. DC drives rely on brushes and commutators, which demand regular inspection, cleaning, and replacement to ensure optimal performance. This results in higher maintenance costs and downtime for DC drives compared to the more durable and low-maintenance AC drives.

Cost Considerations: AC Drive vs DC Drive

AC drives generally offer lower initial costs and reduced maintenance expenses compared to DC drives due to simpler construction and fewer components prone to wear. DC drives require more frequent maintenance and replacement of brushes and commutators, increasing long-term operational costs. Energy efficiency in AC drives also contributes to cost savings by lowering power consumption during continuous operation.

Selecting the Right Drive for Your Equipment

Selecting the right drive for your equipment depends on factors such as load type, speed control precision, and energy efficiency requirements. AC drives offer superior energy savings, low maintenance, and are ideal for variable-speed applications with high torque demands. DC drives provide excellent speed control and torque at low speeds, making them suitable for applications requiring precise motor control.

AC drive vs DC drive Infographic

productdif.com

productdif.com