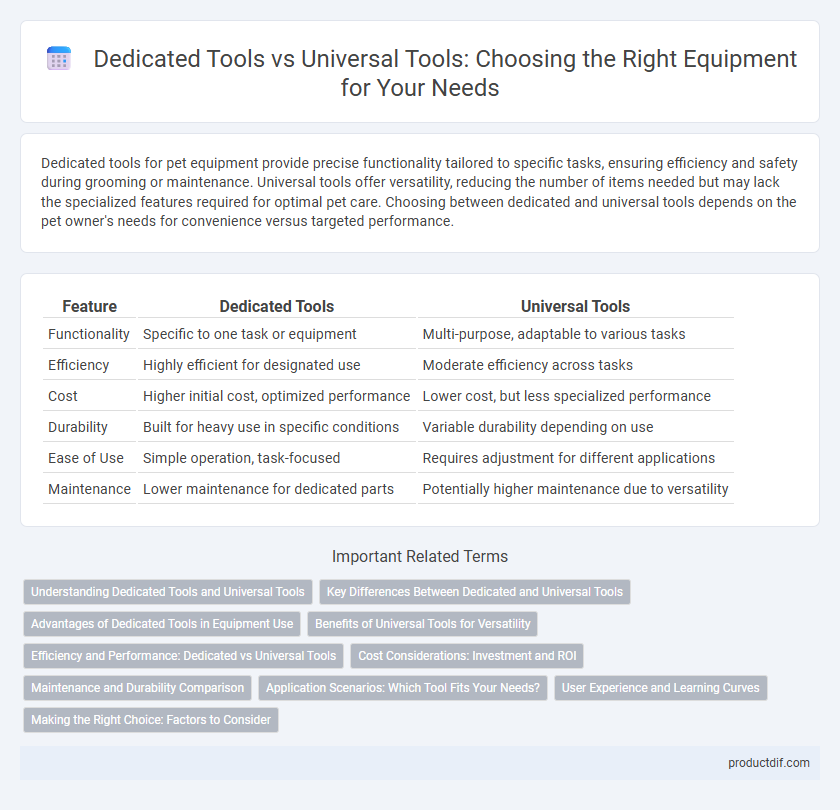

Dedicated tools for pet equipment provide precise functionality tailored to specific tasks, ensuring efficiency and safety during grooming or maintenance. Universal tools offer versatility, reducing the number of items needed but may lack the specialized features required for optimal pet care. Choosing between dedicated and universal tools depends on the pet owner's needs for convenience versus targeted performance.

Table of Comparison

| Feature | Dedicated Tools | Universal Tools |

|---|---|---|

| Functionality | Specific to one task or equipment | Multi-purpose, adaptable to various tasks |

| Efficiency | Highly efficient for designated use | Moderate efficiency across tasks |

| Cost | Higher initial cost, optimized performance | Lower cost, but less specialized performance |

| Durability | Built for heavy use in specific conditions | Variable durability depending on use |

| Ease of Use | Simple operation, task-focused | Requires adjustment for different applications |

| Maintenance | Lower maintenance for dedicated parts | Potentially higher maintenance due to versatility |

Understanding Dedicated Tools and Universal Tools

Dedicated tools are specifically engineered for particular tasks, offering high precision and efficiency in specialized applications such as automotive repair or woodworking. Universal tools provide versatility by accommodating a wide range of functions across different projects, making them essential for general maintenance and multi-purpose use. Understanding the strengths and limitations of dedicated versus universal tools enables professionals to optimize equipment choice for task-specific performance or broader adaptability.

Key Differences Between Dedicated and Universal Tools

Dedicated tools are designed specifically for a single task or product, offering precision and efficiency tailored to that purpose, which enhances performance and reduces errors. Universal tools provide versatility by accommodating a range of uses and applications, making them cost-effective and convenient for varied tasks. Key differences include specialization versus flexibility, with dedicated tools often delivering higher quality outcomes and universal tools prioritizing adaptability across multiple functions.

Advantages of Dedicated Tools in Equipment Use

Dedicated tools offer superior performance due to their specialized design tailored for specific tasks, resulting in increased precision and efficiency. They enhance safety by minimizing the risk of damage or injury typically associated with improper tool use. The durability of dedicated tools also extends equipment lifespan, reducing maintenance costs and downtime.

Benefits of Universal Tools for Versatility

Universal tools offer exceptional versatility by accommodating a wide range of tasks and applications, reducing the need for multiple specialized instruments. Their adaptability enhances efficiency in diverse working environments, making them cost-effective and space-saving for both professionals and hobbyists. This flexibility supports quicker project completion and easier maintenance, proving advantageous over dedicated tools limited to singular functions.

Efficiency and Performance: Dedicated vs Universal Tools

Dedicated tools offer superior efficiency and performance by being specifically designed for particular tasks, resulting in faster completion times and higher precision. Universal tools provide versatility but often sacrifice optimal performance and may increase the time required for specialized jobs. Investing in dedicated tools enhances workflow accuracy and reduces fatigue compared to the broader, less optimized use of universal tools.

Cost Considerations: Investment and ROI

Dedicated tools often require higher upfront investment but deliver superior efficiency and precision, leading to faster ROI in specialized tasks. Universal tools offer cost savings in initial purchase and versatility across various applications, potentially reducing overall equipment expenses. Evaluating project scope and frequency of use ensures optimal balance between investment and long-term financial benefits.

Maintenance and Durability Comparison

Dedicated tools often offer superior maintenance ease and longer durability due to their specialized design tailored for specific tasks, reducing wear and tear. Universal tools, while more versatile, typically experience faster deterioration and require more frequent maintenance because they endure varied stresses outside their optimal use. Investing in dedicated tools enhances equipment longevity and minimizes downtime, making them ideal for high-demand maintenance environments.

Application Scenarios: Which Tool Fits Your Needs?

Dedicated tools offer precision and efficiency tailored to specific tasks, making them ideal for specialized applications where accuracy and speed are critical. Universal tools provide versatility across various functions, suitable for general use and environments requiring multi-functionality without frequent tool changes. Selecting between dedicated and universal tools depends on the complexity of the project, frequency of use, and the need for specialized performance versus broad adaptability.

User Experience and Learning Curves

Dedicated tools offer a streamlined user experience by providing specialized functions tailored to specific tasks, reducing complexity and minimizing the learning curve for new users. Universal tools, while versatile and cost-effective, often require users to navigate a broader range of features, leading to longer learning periods and potential usability challenges. Prioritizing dedicated tools can enhance productivity and ease of use, especially for professionals seeking efficiency in specialized workflows.

Making the Right Choice: Factors to Consider

Choosing between dedicated tools and universal tools hinges on the specific task requirements, budget constraints, and long-term usage goals. Dedicated tools offer superior precision and efficiency for specialized tasks, while universal tools provide versatility and cost-effectiveness for handling multiple applications. Assessing factors such as frequency of use, requirement for accuracy, and storage capacity ensures optimal equipment investment.

Dedicated tools vs Universal tools Infographic

productdif.com

productdif.com