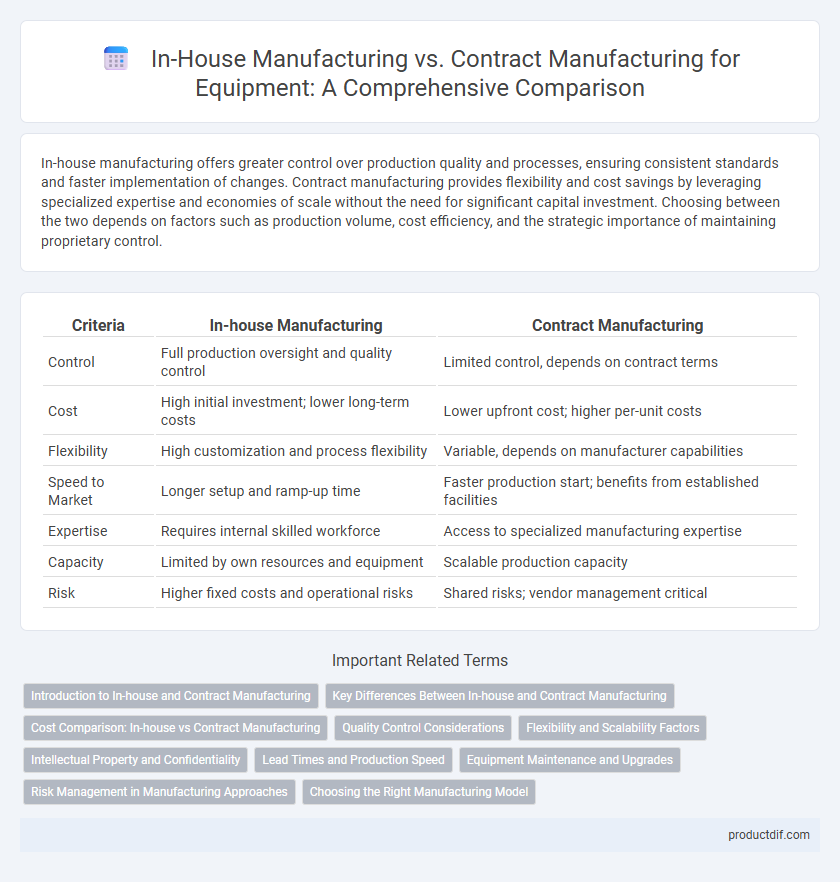

In-house manufacturing offers greater control over production quality and processes, ensuring consistent standards and faster implementation of changes. Contract manufacturing provides flexibility and cost savings by leveraging specialized expertise and economies of scale without the need for significant capital investment. Choosing between the two depends on factors such as production volume, cost efficiency, and the strategic importance of maintaining proprietary control.

Table of Comparison

| Criteria | In-house Manufacturing | Contract Manufacturing |

|---|---|---|

| Control | Full production oversight and quality control | Limited control, depends on contract terms |

| Cost | High initial investment; lower long-term costs | Lower upfront cost; higher per-unit costs |

| Flexibility | High customization and process flexibility | Variable, depends on manufacturer capabilities |

| Speed to Market | Longer setup and ramp-up time | Faster production start; benefits from established facilities |

| Expertise | Requires internal skilled workforce | Access to specialized manufacturing expertise |

| Capacity | Limited by own resources and equipment | Scalable production capacity |

| Risk | Higher fixed costs and operational risks | Shared risks; vendor management critical |

Introduction to In-house and Contract Manufacturing

In-house manufacturing involves producing equipment within a company's own facilities, offering direct control over quality, production schedules, and intellectual property. Contract manufacturing outsources production to specialized third-party companies, enabling cost savings, scalability, and access to advanced technologies without investing in new infrastructure. Choosing between in-house and contract manufacturing depends on factors such as production volume, cost efficiency, and strategic focus on core competencies.

Key Differences Between In-house and Contract Manufacturing

In-house manufacturing offers direct control over production processes, quality standards, and inventory management, enabling rapid adjustments and fostering proprietary technology development. Contract manufacturing emphasizes cost efficiency, scalability, and access to specialized expertise but may pose risks related to intellectual property protection and less direct oversight of quality. Key differences center on control, cost structure, flexibility, and resource allocation, influencing strategic decisions based on a company's operational priorities and capacity.

Cost Comparison: In-house vs Contract Manufacturing

In-house manufacturing often involves higher upfront capital expenditure due to equipment, labor, and facility costs, but offers long-term savings through full control over production and quality. Contract manufacturing reduces initial investment and operational expenses by outsourcing production to specialized third parties, though it may incur higher per-unit costs and less flexibility. Evaluating cost comparison requires analyzing volume scalability, overhead allocation, and potential hidden expenses such as logistics and quality assurance.

Quality Control Considerations

In-house manufacturing offers direct oversight of quality control processes, enabling immediate detection and correction of defects, which ensures consistent product standards. Contract manufacturing relies heavily on detailed agreements and periodic audits to maintain quality, making supplier selection and communication critical for mitigating risks. Implementing robust quality control systems, including real-time monitoring and standardized testing protocols, is essential regardless of the manufacturing approach to meet industry regulations and customer expectations.

Flexibility and Scalability Factors

In-house manufacturing offers greater control over production processes, enabling rapid adjustments and customization to meet specific equipment requirements, which enhances flexibility. Contract manufacturing provides scalability advantages by leveraging external facilities and expertise, allowing companies to quickly ramp up or down production volumes without significant capital investment. Balancing in-house capabilities with contract manufacturing partnerships optimizes both flexibility in design iterations and scalability in response to market demand.

Intellectual Property and Confidentiality

In-house manufacturing ensures tighter control over intellectual property and confidentiality by limiting access to sensitive designs and processes within the company's premises. Contract manufacturing introduces risks of IP leakage and unauthorized use, necessitating robust legal agreements and monitoring to safeguard proprietary technology. Businesses must evaluate the trade-off between cost efficiency and the security of intellectual assets when choosing between these manufacturing options.

Lead Times and Production Speed

In-house manufacturing offers greater control over lead times and production speed due to direct oversight of processes and workflow adjustments. Contract manufacturing may face variability in lead times caused by external scheduling and capacity constraints, potentially slowing down production speed. Optimizing lead times involves assessing production capacity, equipment efficiency, and communication channels between stakeholders.

Equipment Maintenance and Upgrades

In-house manufacturing offers direct control over equipment maintenance schedules and immediate access to upgrades, ensuring minimal downtime and tailored performance improvements. Contract manufacturing often depends on the vendor's maintenance protocols, which can lead to delays in addressing equipment issues and slower implementation of technological advancements. Prioritizing regular preventive maintenance and timely equipment upgrades in-house enhances operational efficiency and prolongs machinery lifespan.

Risk Management in Manufacturing Approaches

In-house manufacturing offers greater control over quality and production timelines, reducing risks related to supply chain disruptions and intellectual property theft. Contract manufacturing introduces risks such as less oversight on quality standards, dependency on third-party reliability, and potential confidentiality breaches. Effective risk management requires thorough vetting of contract manufacturers and robust in-house quality assurance protocols to mitigate operational uncertainties.

Choosing the Right Manufacturing Model

Selecting the right manufacturing model depends on factors such as production volume, cost control, and intellectual property protection. In-house manufacturing offers greater oversight and customization while contract manufacturing provides scalability and reduced capital investment. Evaluating operational capacity and long-term strategic goals ensures optimal alignment with business needs in equipment production.

In-house Manufacturing vs Contract Manufacturing Infographic

productdif.com

productdif.com