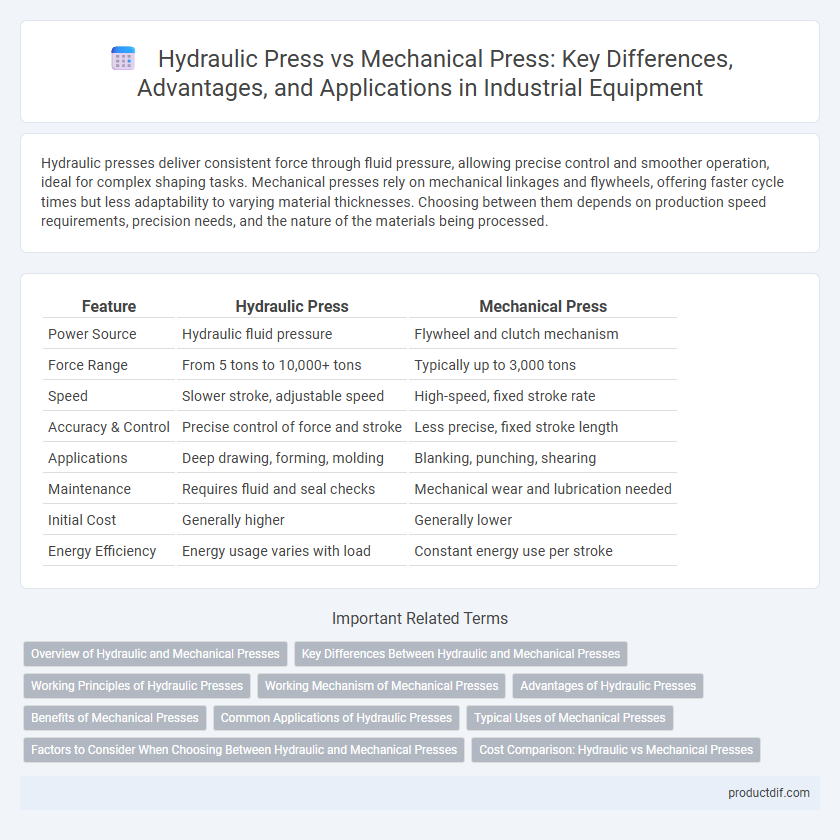

Hydraulic presses deliver consistent force through fluid pressure, allowing precise control and smoother operation, ideal for complex shaping tasks. Mechanical presses rely on mechanical linkages and flywheels, offering faster cycle times but less adaptability to varying material thicknesses. Choosing between them depends on production speed requirements, precision needs, and the nature of the materials being processed.

Table of Comparison

| Feature | Hydraulic Press | Mechanical Press |

|---|---|---|

| Power Source | Hydraulic fluid pressure | Flywheel and clutch mechanism |

| Force Range | From 5 tons to 10,000+ tons | Typically up to 3,000 tons |

| Speed | Slower stroke, adjustable speed | High-speed, fixed stroke rate |

| Accuracy & Control | Precise control of force and stroke | Less precise, fixed stroke length |

| Applications | Deep drawing, forming, molding | Blanking, punching, shearing |

| Maintenance | Requires fluid and seal checks | Mechanical wear and lubrication needed |

| Initial Cost | Generally higher | Generally lower |

| Energy Efficiency | Energy usage varies with load | Constant energy use per stroke |

Overview of Hydraulic and Mechanical Presses

Hydraulic presses use fluid pressure to generate force, offering precise control and adjustable tonnage for diverse applications, including metal forming, molding, and assembly. Mechanical presses rely on mechanical linkages driven by motors or flywheels, providing high-speed operations ideal for stamping, punching, and blanking tasks. Each press type differs in operation speed, force control, and maintenance requirements, influencing their suitability for specific manufacturing processes.

Key Differences Between Hydraulic and Mechanical Presses

Hydraulic presses use fluid pressure to generate force, offering adjustable speed and stroke length, which allows for precise control and versatility in forming operations. Mechanical presses rely on a motor-driven flywheel to deliver a fixed stroke and speed, making them ideal for high-speed, repetitive tasks with consistent output. Key differences include force generation methods, speed variability, and suitability for different material forming applications.

Working Principles of Hydraulic Presses

Hydraulic presses operate based on Pascal's law, utilizing fluid pressure to generate a compressive force that is evenly distributed across the workpiece. These presses consist of a hydraulic cylinder, piston, and fluid reservoir, where applying force to the fluid multiplies the force exerted on the piston, allowing precise control and high tonnage output. Unlike mechanical presses that rely on mechanical linkages, hydraulic presses offer adjustable speed and stroke length, making them ideal for forming complex shapes and materials requiring consistent pressure.

Working Mechanism of Mechanical Presses

Mechanical presses operate using a motor-driven flywheel that stores rotational energy, which is then transferred to a ram through a crank or eccentric shaft, delivering precise and consistent force. This mechanism allows for high-speed, repetitive operations ideal for stamping, punching, and forming metal components. The direct mechanical linkage ensures reliable stroke control and efficiency in mass production environments.

Advantages of Hydraulic Presses

Hydraulic presses offer superior force control and greater versatility compared to mechanical presses, making them ideal for complex forming and pressing tasks. Their ability to generate consistent pressure with adjustable speed enhances precision and reduces material waste. Hydraulic presses also provide quieter operation and require less maintenance, increasing overall efficiency in industrial applications.

Benefits of Mechanical Presses

Mechanical presses offer faster operation speeds, increasing production efficiency in high-volume manufacturing. They provide consistent ram motion that ensures precise and repeatable forming processes, reducing material waste. Their simpler mechanical design generally requires less maintenance, resulting in lower operational costs over time.

Common Applications of Hydraulic Presses

Hydraulic presses are widely used in automotive manufacturing for tasks such as forming, molding, and assembling car body parts due to their ability to deliver consistent force and precise control. These presses excel in metal stamping, deep drawing, and forging processes where variable pressure and slower, controlled movements are essential. Their adaptability makes them ideal for producing complex components in aerospace, construction machinery, and heavy equipment industries.

Typical Uses of Mechanical Presses

Mechanical presses are typically used for high-speed stamping, punching, and forming operations in automotive and appliance manufacturing. They excel in producing large volumes of metal parts with consistent precision and repeatability. These presses are ideal for tasks requiring fast cycle times and moderate to high tonnage capacity.

Factors to Consider When Choosing Between Hydraulic and Mechanical Presses

Selecting between hydraulic and mechanical presses depends on factors such as force control precision, production speed, and maintenance requirements. Hydraulic presses offer variable force and stroke control ideal for tasks needing consistent pressure, while mechanical presses provide faster cycle rates suited for high-volume operations. Consider aspects like energy consumption, tooling cost, and application-specific requirements to ensure optimal equipment performance.

Cost Comparison: Hydraulic vs Mechanical Presses

Hydraulic presses generally have higher initial costs due to advanced components such as pumps, valves, and cylinders but offer lower maintenance expenses over time thanks to fewer moving parts. Mechanical presses typically require less upfront investment, with simpler mechanisms, but incur increased maintenance costs from wear on gears, clutches, and flywheels. Total cost of ownership favors hydraulic presses in complex, high-precision applications, while mechanical presses may be economical for high-volume, simpler stamping tasks.

Hydraulic press vs mechanical press Infographic

productdif.com

productdif.com