CNC milling offers superior precision and repeatability compared to manual milling by using computer-controlled movements to execute complex designs with high accuracy. Manual milling relies heavily on operator skill, resulting in greater variability and slower production speeds. CNC milling enhances efficiency, reduces human error, and supports more intricate machining tasks, making it ideal for high-volume or detailed manufacturing processes.

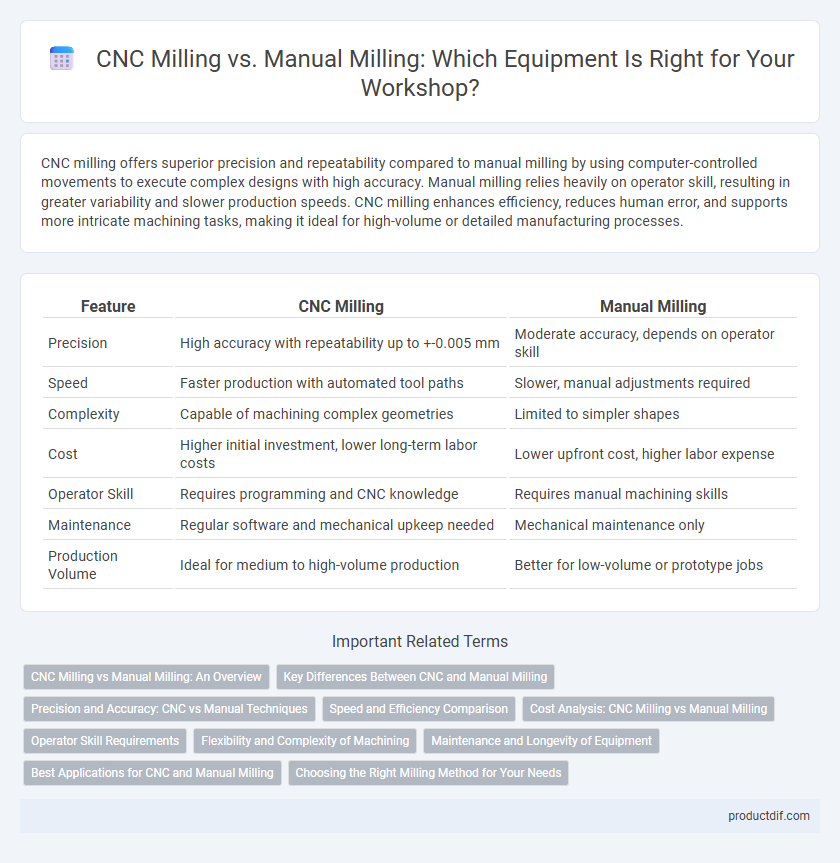

Table of Comparison

| Feature | CNC Milling | Manual Milling |

|---|---|---|

| Precision | High accuracy with repeatability up to +-0.005 mm | Moderate accuracy, depends on operator skill |

| Speed | Faster production with automated tool paths | Slower, manual adjustments required |

| Complexity | Capable of machining complex geometries | Limited to simpler shapes |

| Cost | Higher initial investment, lower long-term labor costs | Lower upfront cost, higher labor expense |

| Operator Skill | Requires programming and CNC knowledge | Requires manual machining skills |

| Maintenance | Regular software and mechanical upkeep needed | Mechanical maintenance only |

| Production Volume | Ideal for medium to high-volume production | Better for low-volume or prototype jobs |

CNC Milling vs Manual Milling: An Overview

CNC milling offers high precision and repeatability by automating the cutting process using computer-controlled tools, significantly reducing human error compared to manual milling. Manual milling relies on operator skill to control the cutting tool directly, which can lead to variations in accuracy and slower production rates. CNC machines enable complex geometries and faster machining speeds, making them ideal for mass production and intricate designs.

Key Differences Between CNC and Manual Milling

CNC milling offers precise automated control through computer programming, enabling complex geometries and consistent repeatability, whereas manual milling relies on operator skill for tool movements and adjustments. CNC machines provide higher efficiency and productivity, handling intricate tasks with minimal human intervention, while manual milling is suited for simpler, low-volume jobs with direct human oversight. The key differences include accuracy, speed, and complexity of operations, with CNC excelling in precision manufacturing and manual milling favoring flexibility and cost-effectiveness for small-scale projects.

Precision and Accuracy: CNC vs Manual Techniques

CNC milling offers superior precision and accuracy through computer-controlled movements, enabling consistent replication of complex designs with tolerances often within microns. Manual milling relies on operator skill, resulting in greater variability and reduced ability to maintain tight tolerances, especially in intricate or repetitive tasks. CNC machines improve productivity while minimizing human error, essential for industries demanding high precision such as aerospace and medical device manufacturing.

Speed and Efficiency Comparison

CNC milling significantly outperforms manual milling in speed and efficiency by automating complex cutting processes with high precision and minimal human intervention. CNC machines operate continuously with consistent accuracy, reducing production time and material wastage compared to manual milling which relies heavily on operator skill and is prone to slower, error-prone execution. Advanced CNC systems can complete intricate milling tasks up to 5 times faster than manual methods, delivering higher productivity in industrial manufacturing environments.

Cost Analysis: CNC Milling vs Manual Milling

CNC milling typically involves higher initial investment due to the cost of advanced machinery and software but offers lower labor costs through automation and increased precision. Manual milling requires less upfront capital but results in higher long-term expenses caused by slower production rates and increased labor requirements. Over time, CNC milling provides better cost-efficiency for high-volume or complex projects, while manual milling remains economical for low-volume or simple tasks.

Operator Skill Requirements

CNC milling requires operators with proficiency in computer programming and machine control software to accurately input designs and manage automated processes. Manual milling demands hands-on skills in tool handling, precision measurement, and manual adjustments to achieve desired tolerances. The complexity of CNC systems generally necessitates advanced technical training, whereas manual milling relies more heavily on practical experience and craftsmanship.

Flexibility and Complexity of Machining

CNC milling offers superior flexibility by enabling precise control over complex geometries and intricate designs through automated programming, allowing for rapid adjustments and high repeatability. Manual milling, while suitable for simpler, less detailed tasks, lacks the ability to efficiently handle complex machining and requires skilled operators to manage variable precision. The advanced software integration and multi-axis capabilities of CNC machines significantly enhance the machining complexity achievable compared to manual methods.

Maintenance and Longevity of Equipment

CNC milling machines require regular software updates and precise calibration to maintain optimal performance, minimizing wear and extending equipment longevity compared to manual milling machines. Automated maintenance alerts in CNC systems help prevent unexpected breakdowns by monitoring tool conditions and machine parameters continuously. Manual milling equipment, while simpler to maintain, often experiences faster wear due to inconsistent operator handling and lacks predictive maintenance capabilities, resulting in shorter machine lifespan.

Best Applications for CNC and Manual Milling

CNC milling excels in high-precision manufacturing, complex geometries, and mass production due to its automated control and repeatability. Manual milling is best suited for simple, low-volume tasks, prototyping, and custom adjustments where hands-on expertise and flexibility are required. Industries like aerospace, automotive, and electronics predominantly use CNC milling for intricate parts, while artisanal workshops or repair shops rely on manual milling for quick modifications and low-cost production.

Choosing the Right Milling Method for Your Needs

CNC milling offers precision and repeatability ideal for complex and high-volume production, while manual milling provides flexibility and cost-effectiveness for small-scale or custom projects. Selecting the right milling method depends on factors such as project complexity, budget, and required tolerances. Evaluating production volume, material type, and desired accuracy ensures optimal equipment utilization and manufacturing efficiency.

CNC milling vs manual milling Infographic

productdif.com

productdif.com