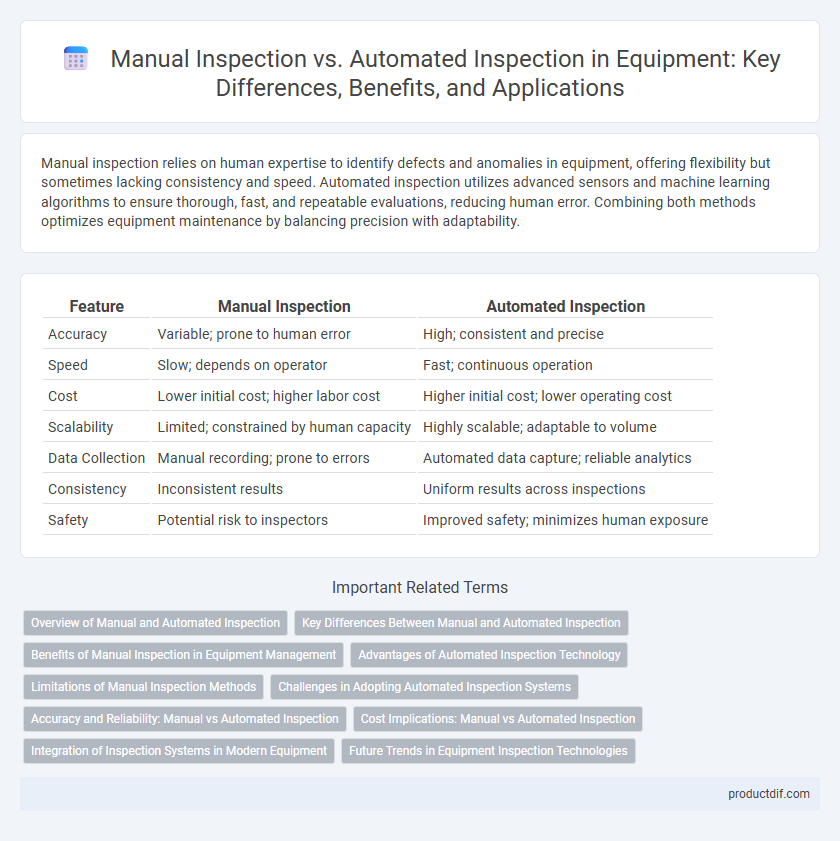

Manual inspection relies on human expertise to identify defects and anomalies in equipment, offering flexibility but sometimes lacking consistency and speed. Automated inspection utilizes advanced sensors and machine learning algorithms to ensure thorough, fast, and repeatable evaluations, reducing human error. Combining both methods optimizes equipment maintenance by balancing precision with adaptability.

Table of Comparison

| Feature | Manual Inspection | Automated Inspection |

|---|---|---|

| Accuracy | Variable; prone to human error | High; consistent and precise |

| Speed | Slow; depends on operator | Fast; continuous operation |

| Cost | Lower initial cost; higher labor cost | Higher initial cost; lower operating cost |

| Scalability | Limited; constrained by human capacity | Highly scalable; adaptable to volume |

| Data Collection | Manual recording; prone to errors | Automated data capture; reliable analytics |

| Consistency | Inconsistent results | Uniform results across inspections |

| Safety | Potential risk to inspectors | Improved safety; minimizes human exposure |

Overview of Manual and Automated Inspection

Manual inspection relies on human expertise to identify defects and ensure product quality through visual and tactile assessment, making it suitable for complex or irregular items. Automated inspection uses advanced technologies like machine vision, sensors, and AI algorithms to perform rapid, precise, and consistent evaluations, ideal for high-volume production lines. Combining both methods optimizes quality control by balancing human judgment with technological efficiency.

Key Differences Between Manual and Automated Inspection

Manual inspection relies on human senses and judgment to detect defects, offering flexibility but limited consistency and speed. Automated inspection utilizes advanced sensors and machine learning algorithms, ensuring high precision, repeatability, and faster throughput for large-scale production. Key differences include accuracy, scalability, and the ability to integrate real-time data analytics for predictive maintenance.

Benefits of Manual Inspection in Equipment Management

Manual inspection in equipment management ensures detailed visual assessment, enabling the detection of subtle wear, corrosion, and misalignments often missed by automated systems. Skilled inspectors bring contextual judgment and immediate decision-making, improving maintenance accuracy and equipment reliability. This hands-on approach supports thorough documentation and real-time adjustments, enhancing overall safety and reducing unexpected downtime.

Advantages of Automated Inspection Technology

Automated inspection technology increases accuracy by minimizing human error and providing consistent, repeatable results in equipment monitoring. It enhances efficiency through faster data acquisition and real-time analysis, enabling prompt detection of defects or malfunctions. Integration with predictive maintenance systems reduces downtime and lowers operational costs.

Limitations of Manual Inspection Methods

Manual inspection methods face significant limitations due to human error, inconsistency, and fatigue, which reduce accuracy and reliability. The process is time-consuming and less efficient compared to automated systems, leading to slower identification of defects or anomalies. Manual inspections often struggle with complex or microscopic issues that require high precision, which advanced automated technologies can detect more effectively.

Challenges in Adopting Automated Inspection Systems

Automated inspection systems face challenges such as high initial investment costs, complex integration with existing production lines, and the need for specialized technical expertise for operation and maintenance. Inconsistent detection accuracy due to varying product types and environmental factors can also limit automation effectiveness. Overcoming these obstacles requires tailored solutions and continuous calibration to ensure reliable performance in diverse manufacturing settings.

Accuracy and Reliability: Manual vs Automated Inspection

Automated inspection systems deliver higher accuracy by minimizing human error and ensuring consistent measurement standards across multiple equipment checks. Manual inspection relies heavily on inspector skill and can introduce variability, reducing overall reliability in detecting faults or deviations. Data-driven algorithms in automated tools enhance defect detection rates and enable real-time adjustments, boosting inspection reliability in complex manufacturing environments.

Cost Implications: Manual vs Automated Inspection

Manual inspection involves higher labor costs due to the need for skilled technicians performing repetitive tasks, leading to increased time and expenses. Automated inspection systems require significant upfront investment in advanced technology and maintenance but reduce long-term operational costs by increasing inspection speed and accuracy. Over time, automated inspection often results in lower total cost of ownership through enhanced efficiency and minimized human error compared to manual methods.

Integration of Inspection Systems in Modern Equipment

Integration of manual and automated inspection systems in modern equipment enhances precision and efficiency, combining human expertise with advanced sensor technology. Automated inspection leverages AI-driven image recognition and real-time data analysis to identify defects faster than traditional manual methods. Seamless integration enables adaptive quality control processes, reducing downtime and ensuring consistent product standards across manufacturing lines.

Future Trends in Equipment Inspection Technologies

Future trends in equipment inspection technologies emphasize increased integration of AI-driven automated inspection systems that enhance accuracy, reduce human error, and accelerate maintenance processes. Advanced sensors combined with real-time data analytics enable predictive maintenance, minimizing downtime and extending equipment lifespan. Enhanced robotic inspection tools equipped with machine learning algorithms offer scalable solutions for complex infrastructure monitoring in industries such as manufacturing, energy, and aerospace.

Manual inspection vs Automated inspection Infographic

productdif.com

productdif.com