Off-the-shelf equipment solutions offer immediate availability and cost-effectiveness for standard applications, reducing installation time and simplifying maintenance. Custom-built solutions provide tailored performance specifications and scalability, ensuring precise alignment with unique operational requirements and future growth. Choosing between these options depends on balancing initial investment, flexibility, and long-term efficiency to optimize overall equipment productivity.

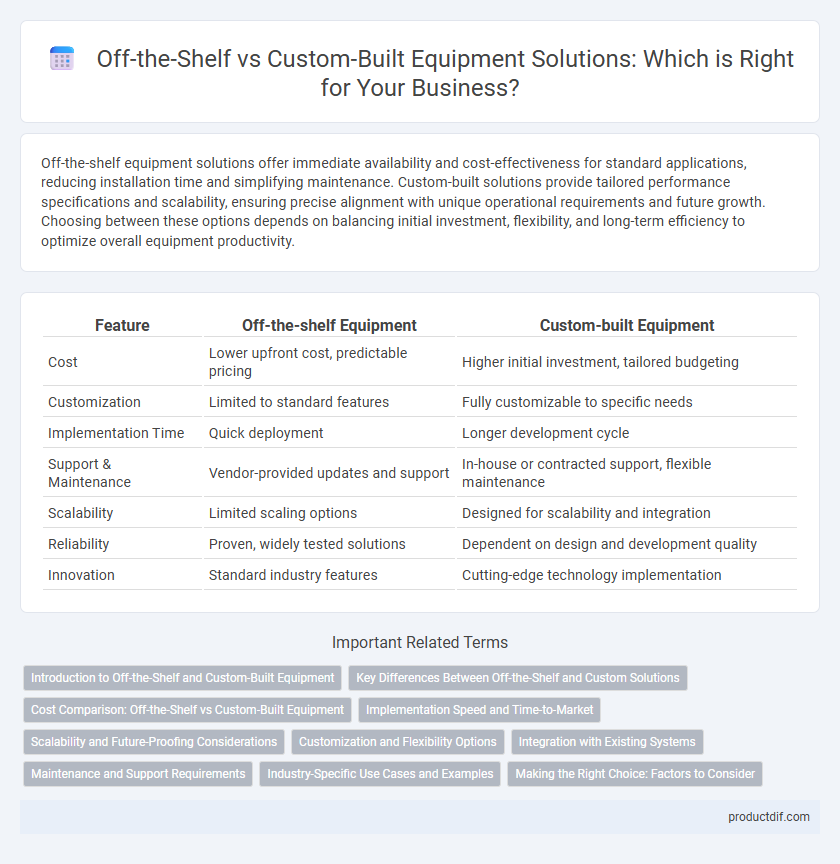

Table of Comparison

| Feature | Off-the-shelf Equipment | Custom-built Equipment |

|---|---|---|

| Cost | Lower upfront cost, predictable pricing | Higher initial investment, tailored budgeting |

| Customization | Limited to standard features | Fully customizable to specific needs |

| Implementation Time | Quick deployment | Longer development cycle |

| Support & Maintenance | Vendor-provided updates and support | In-house or contracted support, flexible maintenance |

| Scalability | Limited scaling options | Designed for scalability and integration |

| Reliability | Proven, widely tested solutions | Dependent on design and development quality |

| Innovation | Standard industry features | Cutting-edge technology implementation |

Introduction to Off-the-Shelf and Custom-Built Equipment

Off-the-shelf equipment offers standardized features and immediate availability, making it ideal for common operational needs with predictable performance. Custom-built equipment provides tailored specifications and scalability, addressing unique challenges and integrating seamlessly with specialized workflows. Evaluating project requirements and budget constraints determines the optimal choice between off-the-shelf and custom-built solutions.

Key Differences Between Off-the-Shelf and Custom Solutions

Off-the-shelf equipment solutions offer immediate availability and lower initial costs, making them ideal for standard operational needs and rapid deployment. Custom-built solutions provide tailored features, scalability, and integration capabilities designed to meet specific business requirements, often resulting in higher long-term value but increased upfront investment. Key differences include customization level, implementation time, cost structure, and adaptability to unique workflows.

Cost Comparison: Off-the-Shelf vs Custom-Built Equipment

Off-the-shelf equipment typically offers lower upfront costs due to mass production, making it budget-friendly for standard applications. Custom-built equipment incurs higher initial expenses driven by design, engineering, and bespoke manufacturing processes tailored to specific operational needs. Long-term investment should consider maintenance and scalability, where custom solutions may yield cost efficiencies despite their premium upfront price.

Implementation Speed and Time-to-Market

Off-the-shelf equipment solutions enable rapid implementation, significantly reducing time-to-market due to pre-designed features and immediate availability. Custom-built equipment requires extended development and testing phases, delaying deployment but offering tailored functionality for specific operational needs. Faster implementation with off-the-shelf options often accelerates project timelines, critical in competitive industries where speed impacts market positioning.

Scalability and Future-Proofing Considerations

Off-the-shelf equipment offers rapid deployment and cost efficiency but may lack scalability and adaptability to evolving operational demands. Custom-built solutions provide tailored scalability options and are designed with future-proofing in mind, accommodating specific growth trajectories and technological advancements. Assessing long-term scalability and upgrade potential is critical when choosing between standardized products and bespoke equipment.

Customization and Flexibility Options

Custom-built equipment solutions provide unparalleled customization, enabling precise adaptation to specific operational requirements and workflows, unlike off-the-shelf solutions which offer limited flexibility. Tailoring features, materials, and functionalities allows businesses to enhance performance and efficiency while addressing unique challenges that standard equipment cannot. This flexibility supports scalability and integration with existing systems, ensuring long-term value and competitive advantage.

Integration with Existing Systems

Off-the-shelf equipment solutions offer rapid deployment and standardized integration protocols compatible with common industry systems, minimizing setup time. Custom-built solutions provide tailored interfaces and seamless integration with unique legacy software and hardware, ensuring optimal performance and scalability. Evaluating system compatibility and long-term support requirements is crucial when choosing between off-the-shelf and custom-built equipment options.

Maintenance and Support Requirements

Off-the-shelf equipment typically offers standardized maintenance protocols and readily available technical support, reducing downtime and operational costs. Custom-built solutions require specialized maintenance expertise and tailored support services, often leading to higher long-term expenses and potential delays in issue resolution. Evaluating the balance between immediate support accessibility and specialized maintenance needs is crucial for optimizing equipment lifecycle management.

Industry-Specific Use Cases and Examples

Off-the-shelf equipment solutions often provide standardized features suitable for general industry applications, such as modular conveyor systems in manufacturing plants or commercial HVAC units for office buildings. Custom-built equipment caters to specialized industry requirements, like precision robotic arms in automotive assembly lines or bespoke filtration systems for pharmaceutical production. Industry-specific use cases highlight that off-the-shelf solutions excel in cost-efficiency and quick deployment, while custom-built equipment offers tailored performance and compliance with unique operational standards.

Making the Right Choice: Factors to Consider

Selecting between off-the-shelf equipment and custom-built solutions requires evaluating factors such as budget constraints, project specifications, and scalability needs. Off-the-shelf options offer quicker deployment and standardized features, ideal for common requirements, while custom-built equipment provides tailored functionality and integration for unique operational demands. Prioritizing long-term maintenance costs, compatibility with existing systems, and anticipated future modifications ensures the most effective investment in equipment solutions.

Off-the-shelf solution vs custom-built solution Infographic

productdif.com

productdif.com