Laser cutting offers higher precision and cleaner edges, making it ideal for intricate designs and thin materials, while plasma cutting excels in speed and efficiency on thicker, conductive metals. Laser technology uses focused light beams for a fine, narrow cut with minimal heat distortion, whereas plasma cutting relies on ionized gas to melt and blow away material, which can leave a rougher edge. Selecting between laser and plasma cutting depends on material thickness, desired cut quality, and project budget constraints.

Table of Comparison

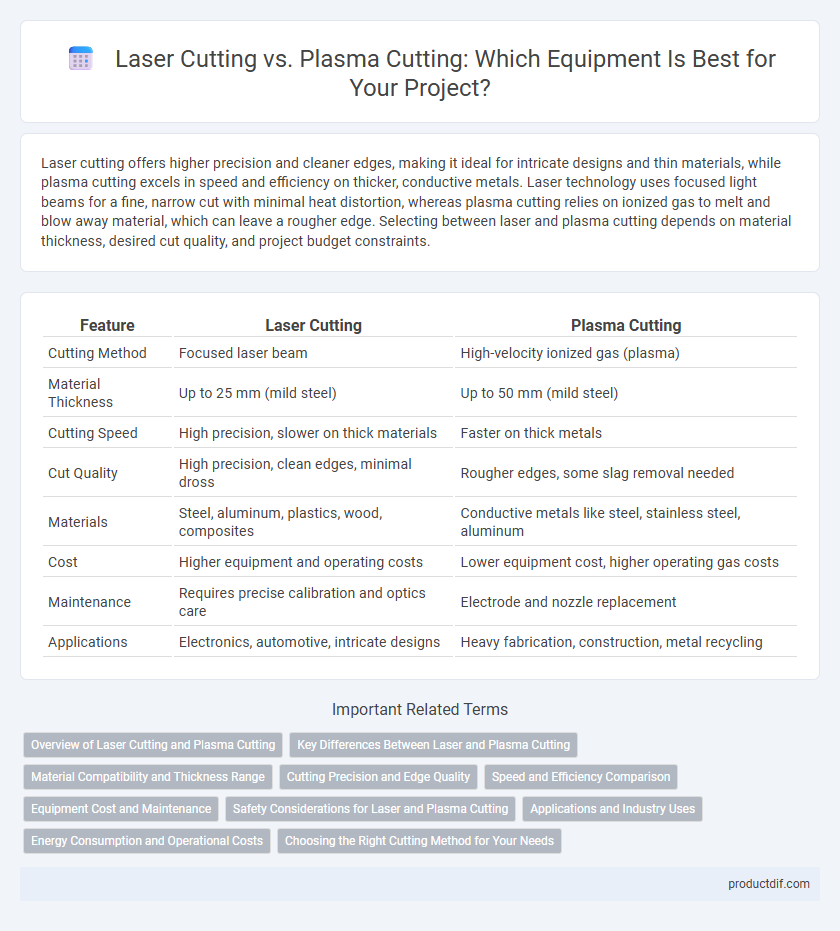

| Feature | Laser Cutting | Plasma Cutting |

|---|---|---|

| Cutting Method | Focused laser beam | High-velocity ionized gas (plasma) |

| Material Thickness | Up to 25 mm (mild steel) | Up to 50 mm (mild steel) |

| Cutting Speed | High precision, slower on thick materials | Faster on thick metals |

| Cut Quality | High precision, clean edges, minimal dross | Rougher edges, some slag removal needed |

| Materials | Steel, aluminum, plastics, wood, composites | Conductive metals like steel, stainless steel, aluminum |

| Cost | Higher equipment and operating costs | Lower equipment cost, higher operating gas costs |

| Maintenance | Requires precise calibration and optics care | Electrode and nozzle replacement |

| Applications | Electronics, automotive, intricate designs | Heavy fabrication, construction, metal recycling |

Overview of Laser Cutting and Plasma Cutting

Laser cutting employs a high-powered laser beam to precisely cut or engrave materials, offering excellent accuracy and smooth edges ideal for metals, plastics, and wood. Plasma cutting uses an ionized gas jet to melt and blow away material, making it suitable for thicker and conductive metals with faster cutting speeds. Both technologies serve distinct industrial needs, with laser cutting favored for fine detail and plasma cutting preferred for heavy-duty applications.

Key Differences Between Laser and Plasma Cutting

Laser cutting uses a focused light beam to produce high-precision, clean cuts with minimal heat-affected zones, ideal for thin materials and intricate designs. Plasma cutting employs an ionized gas jet to cut through thicker, electrically conductive metals quickly but with a rougher edge and wider kerf. Laser cutting excels in fine detail and surface finish, while plasma cutting offers cost-effective, fast cutting for heavy-duty industrial applications.

Material Compatibility and Thickness Range

Laser cutting excels in precision and is ideal for thin to medium-thickness materials such as stainless steel, aluminum, and plastics up to about 20 mm thick. Plasma cutting works effectively on thicker materials, including steel, stainless steel, and aluminum, handling thicknesses from 6 mm up to 50 mm or more with faster processing speeds. Material compatibility varies as laser cutting suits reflective and non-ferrous metals with high accuracy, whereas plasma cutting is preferred for conductive metals, especially in heavy-duty industrial applications.

Cutting Precision and Edge Quality

Laser cutting delivers superior cutting precision and edge quality due to its focused light beam, producing clean, sharp edges with minimal material distortion. Plasma cutting, while faster and suitable for thicker metals, generally results in rougher edges and lower accuracy, requiring additional finishing processes. Industries prioritizing intricate designs and fine details favor laser cutting for its ability to achieve tight tolerances and smooth finishes.

Speed and Efficiency Comparison

Laser cutting delivers higher speed and precision for thin to moderately thick materials, enabling efficient, intricate designs with minimal material waste. Plasma cutting excels in speed when cutting thicker, conductive metals, providing robust, cost-effective performance suitable for industrial heavy-duty applications. Both technologies optimize operational efficiency by reducing cutting time and enhancing productivity based on material type and thickness.

Equipment Cost and Maintenance

Laser cutting machines generally have a higher initial equipment cost compared to plasma cutters, driven by advanced technology and precision components. Maintenance expenses for laser cutters tend to be lower due to fewer consumables and less wear on parts, whereas plasma cutting involves frequent replacement of electrodes and nozzles, increasing ongoing costs. Choosing the optimal cutting equipment depends on balancing upfront investment with long-term maintenance budgets and specific application needs.

Safety Considerations for Laser and Plasma Cutting

Laser cutting systems require strict protective measures, including safety goggles specifically rated for the laser wavelength to prevent eye injuries and fire-resistant clothing to handle intense heat exposure. Plasma cutting produces hazardous fumes and ultraviolet radiation, necessitating the use of proper ventilation systems and welding helmets with high-quality face shields to protect respiratory health and prevent burns. Both methods demand rigorous training in equipment handling and adherence to industry safety standards to minimize risk during operation.

Applications and Industry Uses

Laser cutting offers unparalleled precision and is ideal for industries requiring fine detail, such as aerospace, automotive, and electronics manufacturing, where intricate patterns and tight tolerances are critical. Plasma cutting excels in fabricating thick metal sheets rapidly, making it preferred in heavy industries like construction, shipbuilding, and industrial repair. Both technologies serve distinct roles across sectors, with laser cutting favored for high-precision tasks and plasma cutting utilized for high-speed, heavy-duty metal processing.

Energy Consumption and Operational Costs

Laser cutting typically consumes less energy per unit of material processed compared to plasma cutting, making it more efficient for precision tasks. Plasma cutting equipment often incurs higher operational costs due to greater power requirements and more frequent consumable replacements like electrodes and nozzles. Energy efficiency in laser cutters translates to lower electricity bills and extended equipment lifespan, reducing overall expenditures in industrial applications.

Choosing the Right Cutting Method for Your Needs

Laser cutting offers high precision and cleaner edges, making it ideal for detailed designs and thin materials like stainless steel and aluminum. Plasma cutting excels in speed and is more cost-effective for thicker metals, such as mild steel over 1/2 inch thick. Selecting the right method depends on material thickness, desired edge quality, and budget constraints.

Laser cutting vs plasma cutting Infographic

productdif.com

productdif.com