Rotary die cutting offers faster production speeds and continuous operation, making it ideal for high-volume runs, while flatbed die cutting provides greater precision and flexibility for complex shapes and smaller batches. Rotary systems use cylindrical dies that rotate to cut materials quickly, whereas flatbed systems utilize stationary dies pressed against the material for detailed cuts. Choosing between rotary and flatbed die cutting depends on the specific project requirements, including volume, cut complexity, and material type.

Table of Comparison

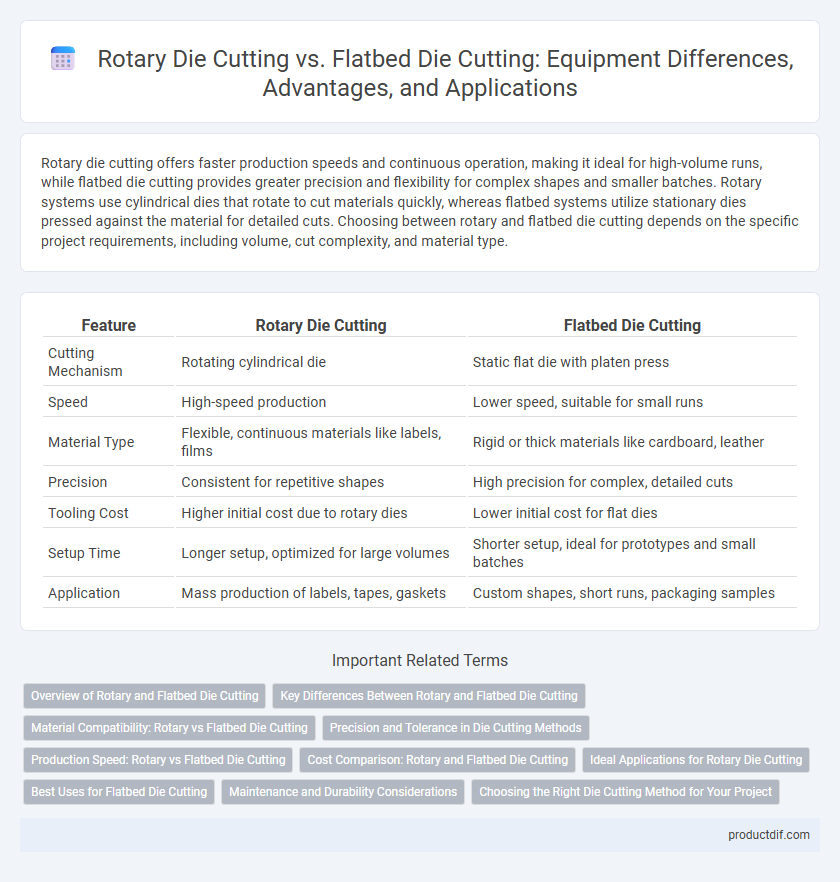

| Feature | Rotary Die Cutting | Flatbed Die Cutting |

|---|---|---|

| Cutting Mechanism | Rotating cylindrical die | Static flat die with platen press |

| Speed | High-speed production | Lower speed, suitable for small runs |

| Material Type | Flexible, continuous materials like labels, films | Rigid or thick materials like cardboard, leather |

| Precision | Consistent for repetitive shapes | High precision for complex, detailed cuts |

| Tooling Cost | Higher initial cost due to rotary dies | Lower initial cost for flat dies |

| Setup Time | Longer setup, optimized for large volumes | Shorter setup, ideal for prototypes and small batches |

| Application | Mass production of labels, tapes, gaskets | Custom shapes, short runs, packaging samples |

Overview of Rotary and Flatbed Die Cutting

Rotary die cutting uses a cylindrical rotary press that enables continuous feeding of materials for high-speed, high-volume production, making it ideal for flexible packaging and labels. Flatbed die cutting employs a reciprocating press with a flat steel rule die that offers precise, sharp cuts suitable for thicker materials like cardboard and corrugated sheets. Rotary die cutting excels in efficiency and speed, while flatbed die cutting provides superior accuracy and versatility for diverse substrates.

Key Differences Between Rotary and Flatbed Die Cutting

Rotary die cutting uses a cylindrical rotary press that continuously cuts materials with high speed and precision, making it ideal for large production runs and intricate designs. Flatbed die cutting employs a flat surface where the die presses down vertically, providing greater accuracy and versatility for thicker or rigid materials but operating at slower speeds. Key differences include speed efficiency, suitability for various material types, and the complexity of achievable cuts, with rotary excelling in volume and flatbed favored for detail and material diversity.

Material Compatibility: Rotary vs Flatbed Die Cutting

Rotary die cutting excels in handling continuous rolls of flexible materials such as paper, film, and foil, ensuring high-speed precision and minimal material waste. Flatbed die cutting is better suited for thicker, rigid substrates like cardboard, plastics, and corrugated materials, providing superior cutting accuracy on irregular shapes and smaller production runs. Material compatibility determines the optimal choice: rotary for fast, flexible roll processing, and flatbed for durable, bulky sheet materials.

Precision and Tolerance in Die Cutting Methods

Rotary die cutting offers higher precision with consistent tolerance levels due to its continuous rotary motion, enabling intricate and complex shapes to be cut rapidly and accurately. Flatbed die cutting provides excellent control over tolerance for thicker materials, allowing precise cuts with minimal distortion, ideal for short runs and high-detail applications. Both methods achieve precise die cuts, but rotary excels in high-speed production with tight tolerances, while flatbed ensures accuracy for heavy-gauge substrates.

Production Speed: Rotary vs Flatbed Die Cutting

Rotary die cutting offers significantly higher production speeds due to its continuous motion, enabling fast and efficient processing of materials in large volumes. Flatbed die cutting operates at slower speeds as it uses a reciprocating press mechanism, ideal for intricate and low-volume jobs requiring precise cuts. Industries prioritizing high throughput typically favor rotary die cutting for rapid output, while flatbed remains preferred for detailed, short-run applications.

Cost Comparison: Rotary and Flatbed Die Cutting

Rotary die cutting generally offers lower per-unit costs due to its continuous operation and higher production speeds, making it ideal for large volume runs. Flatbed die cutting incurs higher setup and maintenance costs, but provides greater precision and flexibility for short runs and complex designs. Choosing between the two depends on balancing initial investment with long-term production efficiency and cost-effectiveness.

Ideal Applications for Rotary Die Cutting

Rotary die cutting excels in high-volume production environments requiring continuous, fast, and precise cutting of flexible materials like labels, packaging films, and adhesives. Its ideal applications include roll-to-roll processing where consistent repeatability and reduced waste are critical. This method is particularly suited for industries such as packaging, labeling, and converting where speed and efficiency drive operational success.

Best Uses for Flatbed Die Cutting

Flatbed die cutting excels in precise, intricate cuts and is ideal for short to medium production runs requiring high accuracy with thick or rigid materials such as cardboard, plastic, and foam. This method offers consistent cutting pressure and minimal material waste, making it suitable for packaging, labels, and specialty printing projects. Flatbed die cutting is preferred for custom shapes and prototypes where detail and quality are paramount.

Maintenance and Durability Considerations

Rotary die cutting equipment generally requires less frequent maintenance due to its continuous rotary motion, which distributes wear evenly across the die, enhancing durability and reducing downtime. Flatbed die cutting machines, while offering precision, often demand more regular maintenance because the reciprocating action can cause increased wear on the die and platen surfaces. The choice between rotary and flatbed die cutting impacts maintenance schedules and equipment lifespan, with rotary systems typically favored for high-volume production environments where durability and reduced service interruptions are critical.

Choosing the Right Die Cutting Method for Your Project

Rotary die cutting offers high-speed production, making it ideal for large-volume projects requiring continuous, intricate shapes with consistent precision. Flatbed die cutting provides versatility and superior cutting pressure, preferred for smaller runs, thicker materials, and detailed designs needing sharp, clean edges. Selecting the right die cutting method depends on factors like project scale, material type, and desired edge quality to ensure optimal efficiency and product quality.

Rotary die cutting vs Flatbed die cutting Infographic

productdif.com

productdif.com