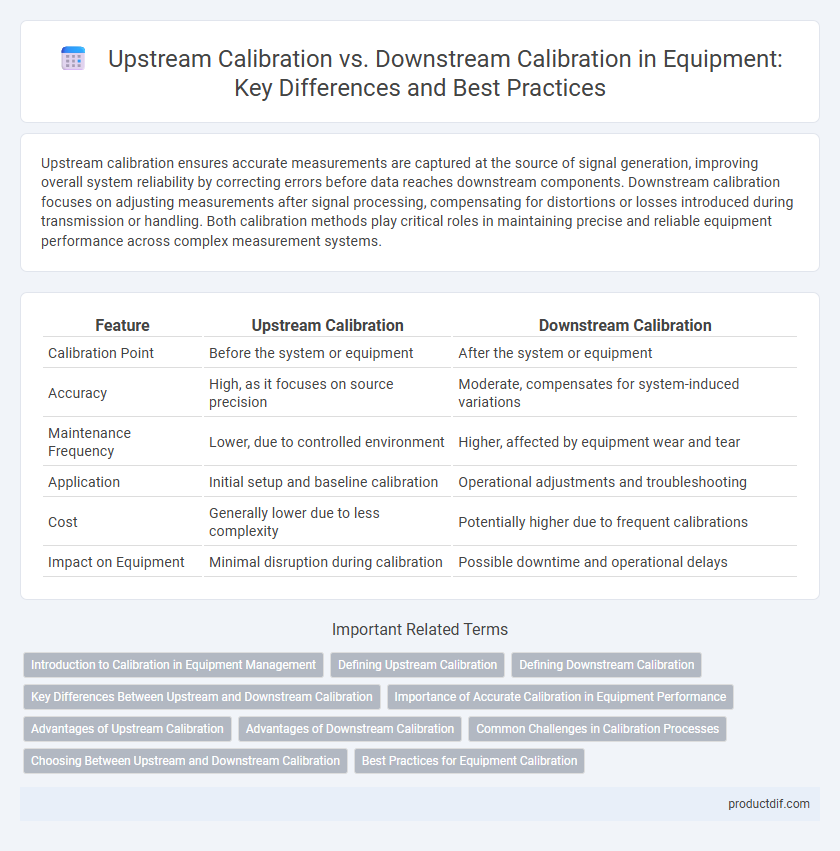

Upstream calibration ensures accurate measurements are captured at the source of signal generation, improving overall system reliability by correcting errors before data reaches downstream components. Downstream calibration focuses on adjusting measurements after signal processing, compensating for distortions or losses introduced during transmission or handling. Both calibration methods play critical roles in maintaining precise and reliable equipment performance across complex measurement systems.

Table of Comparison

| Feature | Upstream Calibration | Downstream Calibration |

|---|---|---|

| Calibration Point | Before the system or equipment | After the system or equipment |

| Accuracy | High, as it focuses on source precision | Moderate, compensates for system-induced variations |

| Maintenance Frequency | Lower, due to controlled environment | Higher, affected by equipment wear and tear |

| Application | Initial setup and baseline calibration | Operational adjustments and troubleshooting |

| Cost | Generally lower due to less complexity | Potentially higher due to frequent calibrations |

| Impact on Equipment | Minimal disruption during calibration | Possible downtime and operational delays |

Introduction to Calibration in Equipment Management

Upstream calibration in equipment management involves adjusting instruments before the measurement process to ensure accuracy at the source, enhancing overall system reliability. Downstream calibration occurs after measurements, verifying instrument output to maintain data integrity and detect deviations. Effective calibration strategies integrate both approaches to optimize equipment performance and minimize errors throughout operational workflows.

Defining Upstream Calibration

Upstream calibration refers to the process of calibrating measurement devices or sensors at the initial stages of data acquisition, ensuring accuracy before signals proceed through the system. This type of calibration helps to detect and correct errors early, preventing the propagation of inaccuracies downstream. Precise upstream calibration is critical for maintaining overall system reliability and optimizing equipment performance in industrial and manufacturing environments.

Defining Downstream Calibration

Downstream calibration refers to the process of verifying and adjusting measurement equipment after it has been installed and is operating within the system, ensuring accuracy under actual working conditions. This calibration focuses on the output signals and final product quality, accounting for environmental factors and system influences that upstream calibration may overlook. Downstream calibration is essential for maintaining operational efficiency and compliance with industry standards in equipment performance.

Key Differences Between Upstream and Downstream Calibration

Upstream calibration involves adjusting instruments and sensors before the process flow, ensuring accuracy at the source of measurement, while downstream calibration is performed after the process to verify overall system performance. The key differences lie in their placement within the process flow, with upstream calibration focusing on individual device precision and downstream calibration emphasizing integrated system accuracy. Upstream calibration typically targets input signal fidelity, whereas downstream calibration assesses output signals to confirm the reliability of the entire equipment setup.

Importance of Accurate Calibration in Equipment Performance

Accurate calibration ensures equipment operates within specified tolerances, directly affecting measurement precision and process efficiency. Upstream calibration adjusts sensors or instruments at the source, preventing error propagation throughout the system, while downstream calibration verifies and corrects readings at the output stage to maintain overall system integrity. Prioritizing both upstream and downstream calibration minimizes downtime, enhances reliability, and supports consistent product quality in industrial operations.

Advantages of Upstream Calibration

Upstream calibration provides real-time monitoring by measuring parameters before the process begins, ensuring immediate detection of deviations and reducing the risk of downstream errors. This method enhances equipment performance and extends its lifespan by preventing contamination or damage caused by inaccurate inputs. Upstream calibration also improves process efficiency and safety by enabling proactive adjustments early in the production line.

Advantages of Downstream Calibration

Downstream calibration offers precise measurement adjustments closer to the end-use point, reducing errors caused by environmental factors or equipment wear in upstream components. It enables real-time monitoring and ensures higher accuracy in the final output, enhancing overall system reliability and performance. This approach simplifies troubleshooting by isolating discrepancies at the output stage, facilitating faster maintenance and minimizing downtime.

Common Challenges in Calibration Processes

Upstream calibration often faces challenges such as environmental variability and limited access to precise reference standards, which can affect measurement accuracy. Downstream calibration struggles with equipment wear and signal degradation, leading to inconsistent calibration results and increased maintenance needs. Both processes require rigorous validation protocols to ensure reliability and minimize measurement uncertainty in critical equipment performance.

Choosing Between Upstream and Downstream Calibration

Choosing between upstream and downstream calibration depends on equipment efficiency and measurement accuracy requirements. Upstream calibration ensures precise input flow measurement, ideal for optimizing process control, while downstream calibration verifies final output quality, critical for regulatory compliance. Evaluating system complexity, maintenance costs, and operational priorities guides the selection of the most effective calibration approach.

Best Practices for Equipment Calibration

Upstream calibration ensures accuracy by verifying and adjusting measurement instruments before the process flow, preventing errors from propagating through the system. Downstream calibration validates equipment performance after the process, confirming that output meets quality standards and specifications. Best practices for equipment calibration include regularly scheduled maintenance, traceability to national standards, and thorough documentation to maintain precision and regulatory compliance.

Upstream calibration vs Downstream calibration Infographic

productdif.com

productdif.com