Die casting and injection molding differ primarily in materials and process: die casting uses molten metal to create strong, durable parts with excellent dimensional accuracy, while injection molding employs plastic pellets melted and injected into molds for lightweight and cost-effective production. Die casting is ideal for metal components requiring high thermal conductivity and mechanical strength, whereas injection molding excels with complex plastic designs and rapid manufacturing cycles. Choosing between these methods depends on the application's material requirements, production volume, and desired part properties.

Table of Comparison

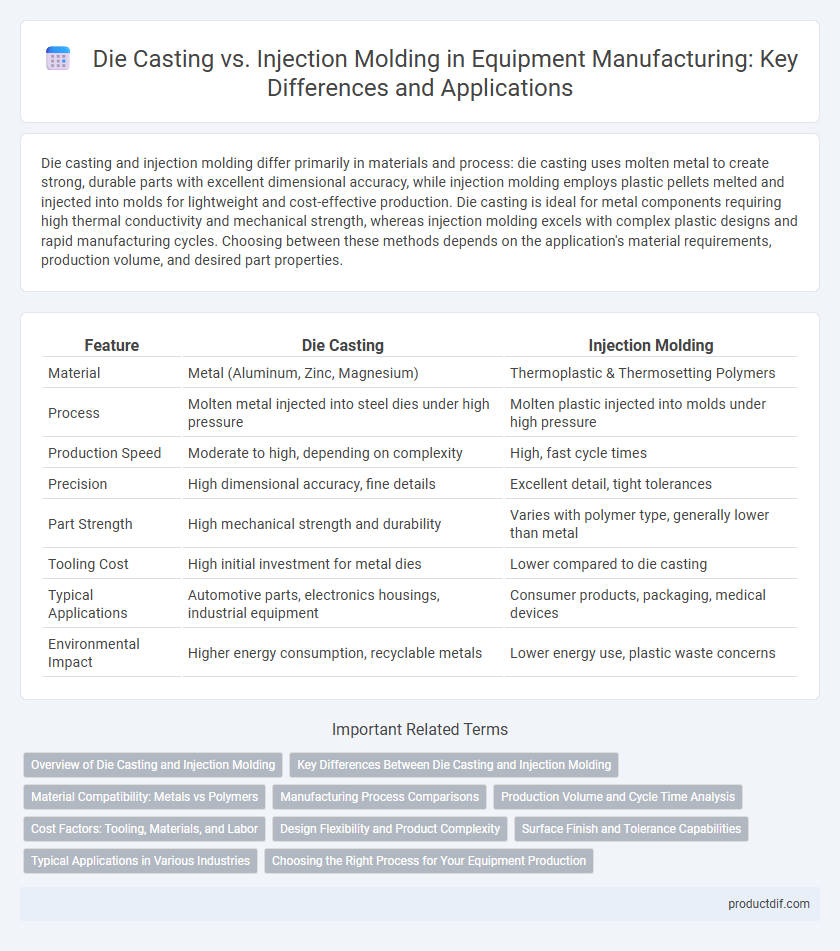

| Feature | Die Casting | Injection Molding |

|---|---|---|

| Material | Metal (Aluminum, Zinc, Magnesium) | Thermoplastic & Thermosetting Polymers |

| Process | Molten metal injected into steel dies under high pressure | Molten plastic injected into molds under high pressure |

| Production Speed | Moderate to high, depending on complexity | High, fast cycle times |

| Precision | High dimensional accuracy, fine details | Excellent detail, tight tolerances |

| Part Strength | High mechanical strength and durability | Varies with polymer type, generally lower than metal |

| Tooling Cost | High initial investment for metal dies | Lower compared to die casting |

| Typical Applications | Automotive parts, electronics housings, industrial equipment | Consumer products, packaging, medical devices |

| Environmental Impact | Higher energy consumption, recyclable metals | Lower energy use, plastic waste concerns |

Overview of Die Casting and Injection Molding

Die casting is a manufacturing process that forces molten metal into a mold cavity under high pressure, producing intricate metal parts with excellent dimensional accuracy and smooth surface finishes. Injection molding involves injecting molten plastic into a mold to create lightweight, complex shapes with high production efficiency and low waste. Both methods offer precise replication of designs, but die casting is ideal for metal components, while injection molding suits plastic products.

Key Differences Between Die Casting and Injection Molding

Die casting utilizes molten metal forced into a mold cavity under high pressure, producing metal parts with exceptional strength and thermal resistance, whereas injection molding involves injecting molten plastic into molds suitable for creating lightweight, complex, and highly detailed plastic components. Die casting offers superior dimensional accuracy and surface finish for metal components, but injection molding allows for faster production cycles and lower tooling costs for plastic products. The choice between die casting and injection molding depends primarily on material requirements, production volume, and part design complexity.

Material Compatibility: Metals vs Polymers

Die casting excels in shaping metals such as aluminum, magnesium, and zinc, offering superior mechanical strength and thermal conductivity for durable equipment components. Injection molding is optimized for polymers including thermoplastics like polypropylene, ABS, and nylon, enabling flexible, lightweight, and chemically resistant parts with complex geometries. Understanding material compatibility guides selecting the appropriate manufacturing process to enhance performance and cost-efficiency in equipment production.

Manufacturing Process Comparisons

Die casting uses molten metal injected at high pressure into steel molds, offering superior strength and thermal conductivity for metal parts, while injection molding employs heated plastic pellets melted and injected into molds, allowing for rapid production of complex, lightweight polymer components. Die casting processes require precise temperature control and cooling cycles to ensure dimensional accuracy and surface finish, whereas injection molding focuses on optimizing melt flow and cooling times to minimize cycle duration and part defects. Equipment choices, such as high-pressure die casting machines versus injection molding presses, influence production speed, tooling costs, and scalability for diverse manufacturing needs.

Production Volume and Cycle Time Analysis

Die casting excels in high-volume production with cycle times ranging from 15 to 60 seconds per part, making it ideal for complex metal components. Injection molding supports even faster cycle times, often between 10 to 30 seconds, suited for high-volume plastic part manufacturing with tighter dimensional control. Production volume heavily influences equipment choice: die casting is preferred for metal parts requiring durability at large scale, while injection molding offers superior speed and flexibility for plastic products.

Cost Factors: Tooling, Materials, and Labor

Die casting typically involves higher initial tooling costs due to the need for durable metal molds, whereas injection molding offers more affordable tooling options using softer materials like aluminum or hardened steel. Material costs vary as die casting primarily uses alloys such as aluminum, zinc, or magnesium, which tend to be more expensive than the plastics used in injection molding, including thermoplastics like polypropylene and ABS. Labor expenses are generally higher in injection molding because of longer cycle times and post-processing requirements, while die casting can achieve faster production rates with less manual intervention.

Design Flexibility and Product Complexity

Die casting offers excellent design flexibility for creating complex metal parts with intricate details and thin walls, making it ideal for high-strength components in automotive and aerospace industries. Injection molding excels in producing highly complex plastic parts with intricate geometries, undercuts, and varying wall thicknesses, especially for consumer electronics and medical devices. Both processes allow for customization, but die casting is preferred for durable metal products, while injection molding provides greater versatility for lightweight, complex plastic designs.

Surface Finish and Tolerance Capabilities

Die casting offers superior surface finish with smooth, thin walls and fine detail, making it ideal for high-precision metal parts with tight tolerance capabilities often within +-0.1 mm. Injection molding excels in producing complex plastic components with consistent dimensional accuracy, typically achieving tolerances around +-0.05 mm, and provides a smooth surface finish suitable for aesthetic applications. Both processes enable high-quality finishes, but die casting is preferred for metal parts requiring enhanced durability, while injection molding is favored for versatile plastic designs with precise tolerances.

Typical Applications in Various Industries

Die casting is widely utilized in the automotive, aerospace, and consumer electronics industries for manufacturing complex metal parts with high strength and thermal conductivity, such as engine blocks and heat sinks. Injection molding dominates in producing plastic components for packaging, medical devices, and household products, offering high precision and faster production cycles. Both methods serve key roles in industrial manufacturing, optimizing material use and production efficiency according to application requirements.

Choosing the Right Process for Your Equipment Production

Die casting offers high-strength metal parts with excellent dimensional accuracy, ideal for heavy-duty equipment components requiring durability and heat resistance. Injection molding excels in producing complex, lightweight plastic parts with rapid cycle times and cost efficiency, suitable for intricate equipment housings and non-metallic elements. Assessing material compatibility, production volume, and mechanical property requirements ensures the optimal manufacturing method for your equipment production needs.

Die casting vs Injection molding Infographic

productdif.com

productdif.com