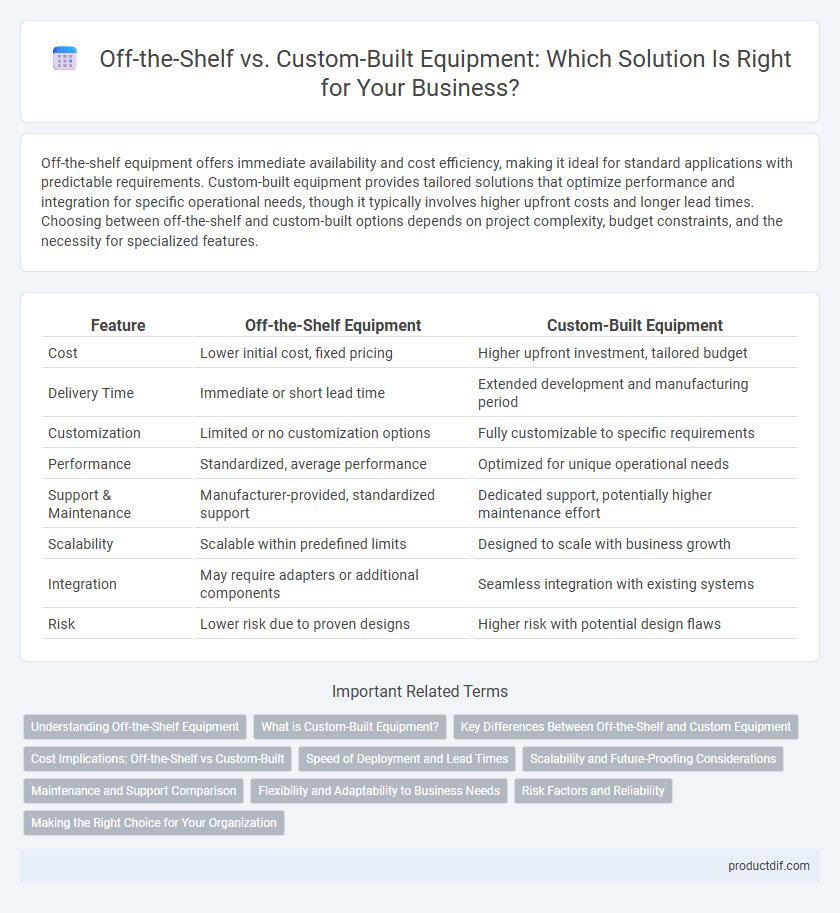

Off-the-shelf equipment offers immediate availability and cost efficiency, making it ideal for standard applications with predictable requirements. Custom-built equipment provides tailored solutions that optimize performance and integration for specific operational needs, though it typically involves higher upfront costs and longer lead times. Choosing between off-the-shelf and custom-built options depends on project complexity, budget constraints, and the necessity for specialized features.

Table of Comparison

| Feature | Off-the-Shelf Equipment | Custom-Built Equipment |

|---|---|---|

| Cost | Lower initial cost, fixed pricing | Higher upfront investment, tailored budget |

| Delivery Time | Immediate or short lead time | Extended development and manufacturing period |

| Customization | Limited or no customization options | Fully customizable to specific requirements |

| Performance | Standardized, average performance | Optimized for unique operational needs |

| Support & Maintenance | Manufacturer-provided, standardized support | Dedicated support, potentially higher maintenance effort |

| Scalability | Scalable within predefined limits | Designed to scale with business growth |

| Integration | May require adapters or additional components | Seamless integration with existing systems |

| Risk | Lower risk due to proven designs | Higher risk with potential design flaws |

Understanding Off-the-Shelf Equipment

Off-the-shelf equipment offers immediate availability and standardized specifications, making it suitable for organizations seeking quick deployment and lower upfront costs. These products are designed for broad compatibility and are extensively tested to ensure reliability across various applications. However, off-the-shelf solutions may lack the tailored features and scalability required for highly specialized or evolving operational needs.

What is Custom-Built Equipment?

Custom-built equipment refers to machinery or devices specifically designed and manufactured to meet unique operational requirements that cannot be fulfilled by standard off-the-shelf products. It offers tailored solutions with precise specifications, ensuring enhanced compatibility, performance, and efficiency for specialized industrial processes. This approach often involves collaboration between designers and end-users to integrate advanced features and custom materials suited to particular applications.

Key Differences Between Off-the-Shelf and Custom Equipment

Off-the-shelf equipment offers standardized features and immediate availability, making it cost-effective for general use with proven reliability. Custom-built equipment is designed to meet specific operational requirements, providing tailored functionality and scalability to enhance performance in specialized applications. Key differences include development time, cost, adaptability, and maintenance complexity, where custom solutions require longer lead time and higher initial investment but deliver optimized efficiency.

Cost Implications: Off-the-Shelf vs Custom-Built

Off-the-shelf equipment generally offers lower upfront costs and faster deployment, making it a cost-effective choice for businesses with standard operational needs. Custom-built equipment, while requiring a higher initial investment, can provide tailored functionality that enhances efficiency and reduces long-term expenses through optimized performance and maintenance. Evaluating total cost of ownership, including installation, training, and future upgrades, is essential when comparing off-the-shelf and custom-built solutions.

Speed of Deployment and Lead Times

Off-the-shelf equipment offers rapid deployment with significantly shorter lead times, often available for immediate purchase and installation. Custom-built solutions require extended lead times due to design, manufacturing, and testing phases tailored to specific requirements. Speed of deployment is critical in fast-paced industries, making off-the-shelf options ideal for urgent operational needs.

Scalability and Future-Proofing Considerations

Off-the-shelf equipment offers quick deployment but often lacks the scalability needed for evolving operational demands, limiting future-proofing capabilities. Custom-built solutions provide tailored scalability options, allowing seamless integration with emerging technologies and adapting to changing business requirements. Investing in custom equipment ensures long-term value by supporting growth and minimizing obsolescence in dynamic environments.

Maintenance and Support Comparison

Off-the-shelf equipment typically benefits from established maintenance protocols, widespread availability of replacement parts, and dedicated technical support from manufacturers, reducing downtime and repair costs. Custom-built equipment may require specialized maintenance expertise and bespoke parts, leading to potentially higher support expenses and longer service times. Evaluating the total cost of ownership should include the ease of accessing skilled technicians and the availability of standardized support resources.

Flexibility and Adaptability to Business Needs

Off-the-shelf equipment offers quick deployment and cost efficiency but often lacks the flexibility to fully adapt to specific business processes. Custom-built solutions provide tailored functionality that aligns precisely with unique operational requirements, enhancing productivity and scalability. Businesses prioritizing adaptability invest in custom-built equipment to support evolving workflows and integrate seamlessly with existing systems.

Risk Factors and Reliability

Off-the-shelf equipment offers proven reliability backed by manufacturer testing but may carry risks related to compatibility and lack of customization for specific operational needs. Custom-built equipment allows tailored design to exact requirements, reducing integration risk, yet poses higher risks due to potential design flaws and longer development times. Evaluating risk factors involves balancing standardized durability against the uncertainty and maintenance demands of bespoke solutions.

Making the Right Choice for Your Organization

Choosing between off-the-shelf and custom-built equipment requires assessing your organization's specific operational needs, budget constraints, and scalability goals. Off-the-shelf solutions offer immediate availability and proven reliability, while custom-built options provide tailored functionality and adaptability to unique workflows. Prioritizing long-term value and integration capabilities ensures the selected equipment aligns with your strategic objectives and growth plans.

Off-the-shelf vs Custom-built Infographic

productdif.com

productdif.com