Production equipment is designed for manufacturing and assembling pet products at scale, ensuring efficiency and consistency. Testing equipment, on the other hand, is used to assess the safety, durability, and quality of pet items, guaranteeing compliance with industry standards. Both types of equipment are essential for delivering reliable and safe pet products to the market.

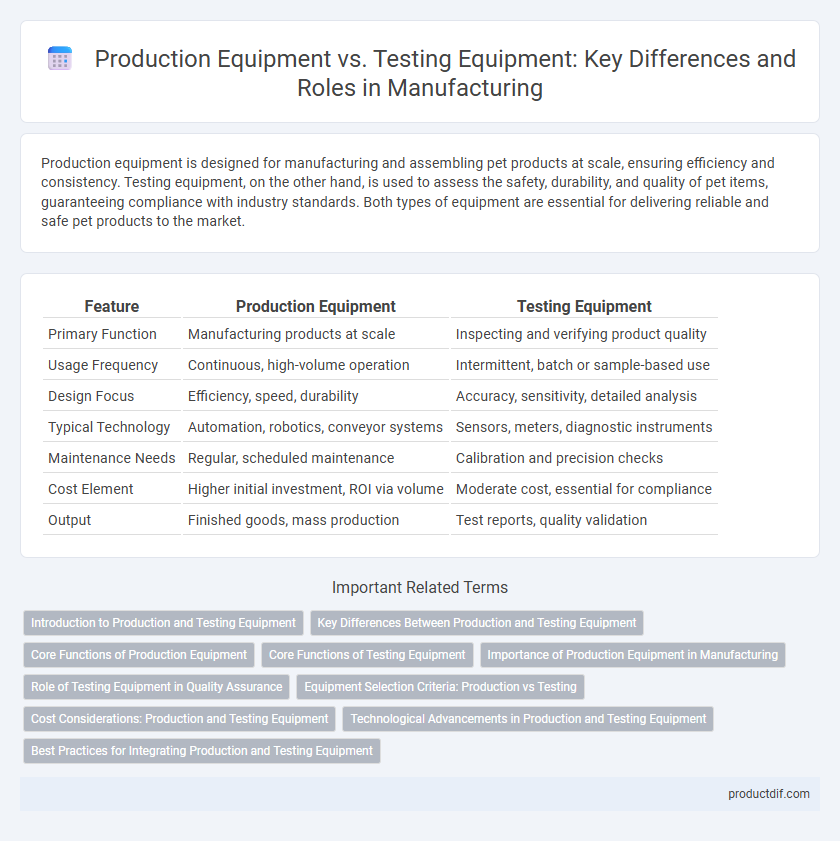

Table of Comparison

| Feature | Production Equipment | Testing Equipment |

|---|---|---|

| Primary Function | Manufacturing products at scale | Inspecting and verifying product quality |

| Usage Frequency | Continuous, high-volume operation | Intermittent, batch or sample-based use |

| Design Focus | Efficiency, speed, durability | Accuracy, sensitivity, detailed analysis |

| Typical Technology | Automation, robotics, conveyor systems | Sensors, meters, diagnostic instruments |

| Maintenance Needs | Regular, scheduled maintenance | Calibration and precision checks |

| Cost Element | Higher initial investment, ROI via volume | Moderate cost, essential for compliance |

| Output | Finished goods, mass production | Test reports, quality validation |

Introduction to Production and Testing Equipment

Production equipment consists of machinery and tools designed to manufacture goods efficiently, ensuring high-volume output and consistent quality. Testing equipment, on the other hand, includes instruments and devices used to evaluate the performance, durability, and safety of products during and after production. Both types of equipment play essential roles in the manufacturing process by enabling quality assurance and operational efficiency.

Key Differences Between Production and Testing Equipment

Production equipment is designed for high-volume manufacturing, emphasizing efficiency, durability, and consistent output to meet production targets. Testing equipment focuses on precision and accuracy to evaluate product quality, performance, and compliance with standards at various stages of the manufacturing process. Key differences include the primary purpose--mass production versus quality assurance--and the level of technical complexity tailored to operational needs.

Core Functions of Production Equipment

Production equipment primarily focuses on the efficient manufacturing and assembly of products by transforming raw materials into finished goods through processes such as machining, molding, and fabrication. These machines are designed for high throughput, precision, and durability, ensuring consistent quality and meeting production targets. Unlike testing equipment, which evaluates product performance and compliance, production equipment drives the core manufacturing workflow essential for operational efficiency.

Core Functions of Testing Equipment

Testing equipment primarily serves to evaluate the quality, performance, and safety of products through precise measurements and diagnostics. Core functions include detecting defects, verifying specifications, and ensuring compliance with industry standards before products proceed to market. These tools enhance reliability by providing critical data that supports production optimization and risk mitigation.

Importance of Production Equipment in Manufacturing

Production equipment plays a crucial role in manufacturing by enabling high-volume output with consistent quality and efficiency, directly influencing overall productivity and cost-effectiveness. Unlike testing equipment, which is vital for quality assurance and defect detection, production equipment drives the actual creation and assembly of products, ensuring meeting supply demands. Investment in advanced production machinery enhances automation capabilities, reduces downtime, and supports scalability in competitive industrial environments.

Role of Testing Equipment in Quality Assurance

Testing equipment plays a critical role in quality assurance by accurately measuring product specifications and identifying defects early in the production process. Unlike production equipment, which focuses on manufacturing and assembly, testing equipment ensures compliance with industry standards and safety regulations. Implementing advanced testing machinery reduces the risk of faulty products reaching customers, thereby improving overall reliability and brand reputation.

Equipment Selection Criteria: Production vs Testing

Production equipment is selected based on factors like throughput capacity, durability under continuous operation, and integration with manufacturing workflows to ensure efficiency and consistency. Testing equipment selection prioritizes precision, sensitivity, and compliance with industry standards to accurately validate product quality and performance. Both categories require evaluating maintenance requirements and cost-effectiveness to optimize operational uptime and reliability.

Cost Considerations: Production and Testing Equipment

Production equipment typically demands higher initial capital investment due to its larger scale, complexity, and continuous operational capabilities. Testing equipment generally incurs lower upfront costs but may require frequent calibration and maintenance to ensure accuracy, impacting long-term expenses. Cost considerations must balance the operational efficiency and lifecycle costs of production equipment against the precision and repeatability intrinsic to testing equipment expenditures.

Technological Advancements in Production and Testing Equipment

Technological advancements in production equipment have introduced automation, precision robotics, and real-time data analytics, significantly enhancing manufacturing efficiency and reducing downtime. Testing equipment has evolved with advanced sensor technologies, AI-driven diagnostic tools, and high-speed imaging systems that ensure higher accuracy and faster quality control processes. Integration of IoT in both production and testing equipment enables seamless communication and predictive maintenance, driving smarter and more reliable industrial operations.

Best Practices for Integrating Production and Testing Equipment

Effective integration of production equipment and testing equipment enhances manufacturing efficiency and product quality by enabling real-time monitoring and immediate defect detection. Implementing standardized communication protocols such as OPC UA and utilizing IoT-enabled devices facilitate seamless data exchange and synchronization between machines. Establishing a centralized control system with predictive maintenance capabilities ensures continuous operation and reduces downtime across both production and testing phases.

Production Equipment vs Testing Equipment Infographic

productdif.com

productdif.com