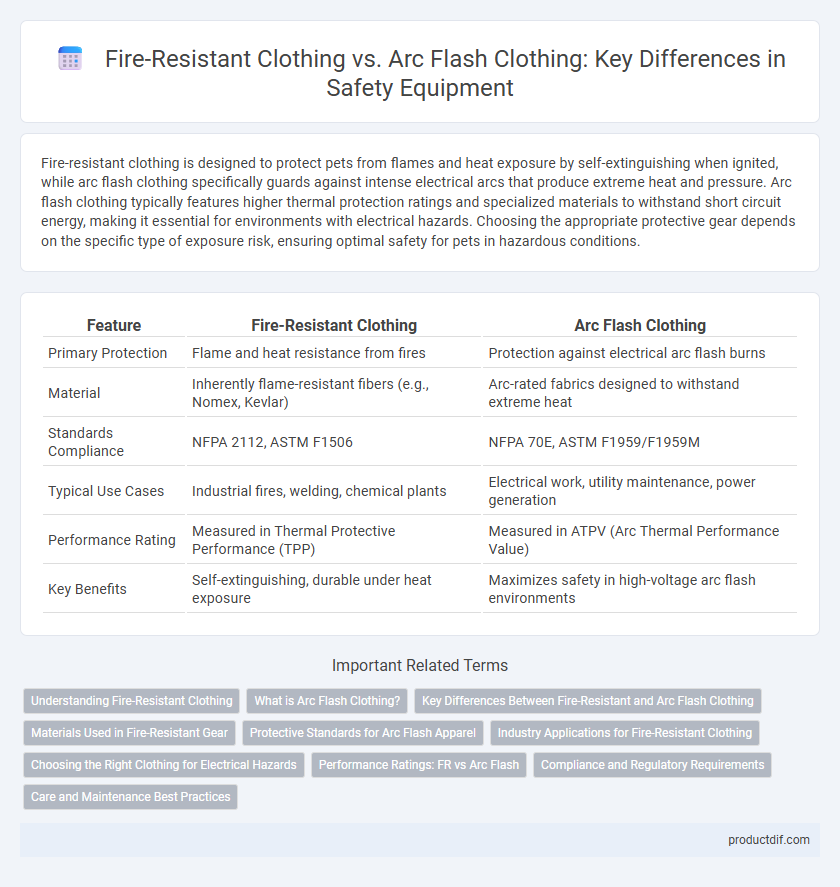

Fire-resistant clothing is designed to protect pets from flames and heat exposure by self-extinguishing when ignited, while arc flash clothing specifically guards against intense electrical arcs that produce extreme heat and pressure. Arc flash clothing typically features higher thermal protection ratings and specialized materials to withstand short circuit energy, making it essential for environments with electrical hazards. Choosing the appropriate protective gear depends on the specific type of exposure risk, ensuring optimal safety for pets in hazardous conditions.

Table of Comparison

| Feature | Fire-Resistant Clothing | Arc Flash Clothing |

|---|---|---|

| Primary Protection | Flame and heat resistance from fires | Protection against electrical arc flash burns |

| Material | Inherently flame-resistant fibers (e.g., Nomex, Kevlar) | Arc-rated fabrics designed to withstand extreme heat |

| Standards Compliance | NFPA 2112, ASTM F1506 | NFPA 70E, ASTM F1959/F1959M |

| Typical Use Cases | Industrial fires, welding, chemical plants | Electrical work, utility maintenance, power generation |

| Performance Rating | Measured in Thermal Protective Performance (TPP) | Measured in ATPV (Arc Thermal Performance Value) |

| Key Benefits | Self-extinguishing, durable under heat exposure | Maximizes safety in high-voltage arc flash environments |

Understanding Fire-Resistant Clothing

Fire-resistant clothing is designed to withstand high temperatures and prevent ignition when exposed to flames, making it crucial for protecting workers in environments with open fire hazards. Unlike arc flash clothing, which specifically guards against intense electrical arcs and associated thermal energy, fire-resistant garments focus on minimizing burn injuries from direct flame contact. Understanding the material composition, such as inherently flame-resistant fibers like Nomex or treated cotton, is essential for selecting appropriate fire-resistant clothing tailored to specific workplace risks.

What is Arc Flash Clothing?

Arc flash clothing is specialized personal protective equipment designed to shield workers from the intense heat, light, and pressure generated by an arc flash incident, typically encountered in electrical environments. It is made from flame-resistant materials that provide a specific arc rating, indicating the level of protection against electrical arcs. Unlike general fire-resistant clothing, arc flash clothing must meet stringent ASTM F1506 standards to ensure safety against the electrical hazards faced by electricians and industrial workers.

Key Differences Between Fire-Resistant and Arc Flash Clothing

Fire-resistant clothing is designed to self-extinguish flames and prevent burn injuries from brief exposure to fire, while arc flash clothing provides protection against extreme heat and intense thermal energy generated during electrical arc flashes. The key difference lies in their hazard focus: fire-resistant (FR) fabrics resist open flames and radiant heat, whereas arc flash garments are tested to meet specific arc thermal performance values (ATPV) to withstand electrical explosions. Selection depends on workplace risks, with arc flash clothing mandatory for electrical tasks and fire-resistant clothing suitable for environments with fire hazards but no electrical exposure.

Materials Used in Fire-Resistant Gear

Fire-resistant clothing commonly uses materials like Nomex, Kevlar, and Modacrylic, which provide heat and flame resistance by forming a protective barrier that delays ignition and burns slowly. Arc flash clothing incorporates similar fibers but often includes enhanced layers and specialized treatments to resist extreme thermal energy and electric arcs, offering superior protection against high-intensity flashes. Both types emphasize fabric durability and protective coatings to maintain safety under hazardous conditions in industrial and firefighting environments.

Protective Standards for Arc Flash Apparel

Arc flash clothing adheres to stringent protective standards such as NFPA 70E and ASTM F1506, designed specifically to mitigate electrical arc hazards by limiting exposure to thermal energy. Fire-resistant clothing, typically meeting NFPA 2112 standards, offers protection against flash fires but lacks the specialized rating required for electrical arc flash resistance. Choosing arc flash apparel ensures compliance with safety regulations and effective protection in high-voltage environments, reducing the risk of severe burns caused by electrical incidents.

Industry Applications for Fire-Resistant Clothing

Fire-resistant clothing is primarily utilized in industries such as oil and gas, electrical utilities, and firefighting, where workers are exposed to open flames, flash fires, or intense heat. These garments are engineered to self-extinguish and prevent burn injuries during sudden exposure to fire hazards. Unlike arc flash clothing, which is designed specifically to protect against electrical arc flashes, fire-resistant clothing offers broad protection against various combustion-related risks in high-temperature industrial environments.

Choosing the Right Clothing for Electrical Hazards

Fire-resistant clothing is designed to protect workers from flames and heat exposure by self-extinguishing upon contact with fire, while arc flash clothing specifically safeguards against the extreme thermal energy released during electrical arc incidents. Selecting the right clothing for electrical hazards depends on the hazard's nature, with arc flash-rated gear required where high-intensity electrical arc exposure is possible, and fire-resistant fabrics suitable for general flame risks. Evaluating the incident energy level and workplace electrical conditions ensures optimal protection and compliance with safety standards such as NFPA 70E and ASTM F1506.

Performance Ratings: FR vs Arc Flash

Fire-resistant (FR) clothing is rated based on its ability to self-extinguish and prevent flame spread, typically evaluated using standards like NFPA 2112 for flash fire protection. Arc flash clothing performance ratings focus on the arc thermal performance value (ATPV), which measures garment resistance to electric arc exposure according to standards such as NFPA 70E and ASTM F1959. Understanding these specific ratings is crucial to selecting appropriate safety gear that meets the required hazard protection levels in industrial environments.

Compliance and Regulatory Requirements

Fire-resistant clothing complies with NFPA 2112 standards for protection against flash fires, while arc flash clothing meets NFPA 70E requirements to prevent electrical arc hazards. Employers must ensure garments are certified to the relevant standards to maintain OSHA compliance and safeguard workers from specific fire and electrical risks. Selecting appropriate clothing based on hazard assessment ensures adherence to regulatory mandates and reduces workplace injury liabilities.

Care and Maintenance Best Practices

Fire-resistant clothing requires regular inspection for tears, contamination, and wear, followed by gentle washing with mild detergents to maintain fabric integrity and protective properties. Arc flash clothing demands adherence to manufacturer guidelines, including avoiding bleach and fabric softeners, and frequent thermal testing to ensure sustained performance under high-heat exposure. Both types should be stored in clean, dry environments away from direct sunlight to prevent degradation of flame-resistant treatments.

Fire-resistant clothing vs Arc flash clothing Infographic

productdif.com

productdif.com