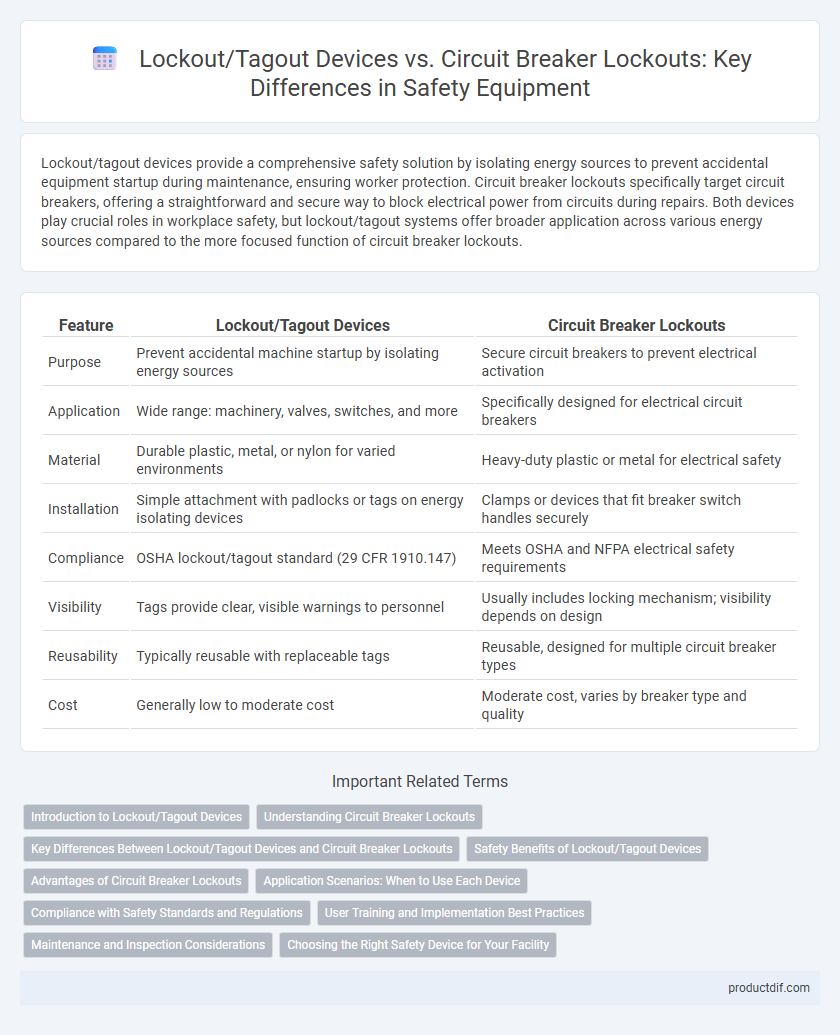

Lockout/tagout devices provide a comprehensive safety solution by isolating energy sources to prevent accidental equipment startup during maintenance, ensuring worker protection. Circuit breaker lockouts specifically target circuit breakers, offering a straightforward and secure way to block electrical power from circuits during repairs. Both devices play crucial roles in workplace safety, but lockout/tagout systems offer broader application across various energy sources compared to the more focused function of circuit breaker lockouts.

Table of Comparison

| Feature | Lockout/Tagout Devices | Circuit Breaker Lockouts |

|---|---|---|

| Purpose | Prevent accidental machine startup by isolating energy sources | Secure circuit breakers to prevent electrical activation |

| Application | Wide range: machinery, valves, switches, and more | Specifically designed for electrical circuit breakers |

| Material | Durable plastic, metal, or nylon for varied environments | Heavy-duty plastic or metal for electrical safety |

| Installation | Simple attachment with padlocks or tags on energy isolating devices | Clamps or devices that fit breaker switch handles securely |

| Compliance | OSHA lockout/tagout standard (29 CFR 1910.147) | Meets OSHA and NFPA electrical safety requirements |

| Visibility | Tags provide clear, visible warnings to personnel | Usually includes locking mechanism; visibility depends on design |

| Reusability | Typically reusable with replaceable tags | Reusable, designed for multiple circuit breaker types |

| Cost | Generally low to moderate cost | Moderate cost, varies by breaker type and quality |

Introduction to Lockout/Tagout Devices

Lockout/tagout devices are essential safety tools designed to prevent accidental equipment energization during maintenance by securing energy-isolating devices in the off position. These devices include padlocks, hasps, and valve covers that ensure machinery remains de-energized until maintenance is complete. Circuit breaker lockouts are a specific subset of lockout/tagout devices that focus on locking circuit breakers to enhance electrical safety and compliance with OSHA standards.

Understanding Circuit Breaker Lockouts

Circuit breaker lockouts are specialized safety devices designed to secure circuit breakers in the off position, preventing accidental re-energization during maintenance. These lockouts enhance workplace safety by physically blocking the breaker switch, ensuring compliance with OSHA lockout/tagout regulations. Compared to general lockout/tagout devices, circuit breaker lockouts are tailored to fit specific breaker types, providing a reliable and standardized method for electrical isolation.

Key Differences Between Lockout/Tagout Devices and Circuit Breaker Lockouts

Lockout/tagout devices provide comprehensive control by physically isolating energy sources across various equipment types, ensuring maintenance safety by preventing accidental energization. Circuit breaker lockouts specifically target circuit breakers to secure electrical panels, offering a streamlined method for controlling electrical power shutdowns. The key difference lies in lockout/tagout devices' versatility for multiple energy sources versus circuit breaker lockouts' specialized focus on electrical circuit isolation.

Safety Benefits of Lockout/Tagout Devices

Lockout/tagout devices provide comprehensive energy isolation by securely locking machinery controls, preventing accidental startups during maintenance and reducing workplace injuries. These devices offer versatility for various types of equipment and energy sources, ensuring improved compliance with OSHA safety standards. Compared to circuit breaker lockouts, lockout/tagout systems enable more effective communication through tagging, enhancing overall safety awareness among workers.

Advantages of Circuit Breaker Lockouts

Circuit breaker lockouts offer enhanced protection by physically securing breakers in the off position, preventing accidental re-energization during maintenance. Their universal compatibility with various breaker types ensures a versatile and reliable safety solution across different electrical systems. Compact and easy to install, circuit breaker lockouts improve efficiency while reducing the risk of electrical hazards in industrial and commercial environments.

Application Scenarios: When to Use Each Device

Lockout/tagout devices are essential for safely isolating energy sources during maintenance on complex machinery and industrial equipment, preventing accidental startup. Circuit breaker lockouts are specifically designed for electrical panels, restricting access to switches in commercial or residential settings where quick disabling is necessary. Use lockout/tagout devices for comprehensive energy control across multiple energy sources, and circuit breaker lockouts for straightforward lockout of electrical circuits.

Compliance with Safety Standards and Regulations

Lockout/tagout devices provide comprehensive control over energy sources by isolating machines during maintenance, aligning closely with OSHA's Control of Hazardous Energy standard (29 CFR 1910.147). Circuit breaker lockouts specifically secure electrical panels, ensuring compliance with NFPA 70E requirements for electrical safety in the workplace. Both devices are essential for meeting regulatory mandates, but lockout/tagout systems offer broader application across various hazardous energy environments.

User Training and Implementation Best Practices

User training for lockout/tagout devices emphasizes comprehensive understanding of energy isolation procedures, specific device applications, and regulatory compliance under OSHA standards, ensuring workers can effectively prevent accidental energization. Circuit breaker lockouts require focused training on proper installation, verifying lockout points, and periodic inspection to maintain equipment integrity and worker safety. Implementation best practices involve combining practical hands-on sessions with regular refresher courses and audits to reinforce correct usage and minimize human error.

Maintenance and Inspection Considerations

Lockout/tagout devices provide comprehensive isolation for various energy sources during maintenance, ensuring maximum worker safety by preventing accidental equipment energization. Circuit breaker lockouts offer quick and effective control specifically for electrical circuits, enabling precise isolation and easier inspection of electrical panels. Regular inspection of both devices ensures integrity and compliance with safety standards, reducing risks of equipment malfunction or unauthorized access during maintenance.

Choosing the Right Safety Device for Your Facility

Selecting the appropriate safety device between lockout/tagout devices and circuit breaker lockouts depends on your facility's specific operational requirements and the type of equipment involved. Lockout/tagout devices provide comprehensive control over energy isolation for various machinery, while circuit breaker lockouts offer focused protection by preventing circuit breaker operation, ideal for electrical systems. Evaluating the complexity of your equipment, regulatory compliance needs, and ease of device application ensures optimal safety and minimizes risks during maintenance.

Lockout/tagout devices vs Circuit breaker lockouts Infographic

productdif.com

productdif.com