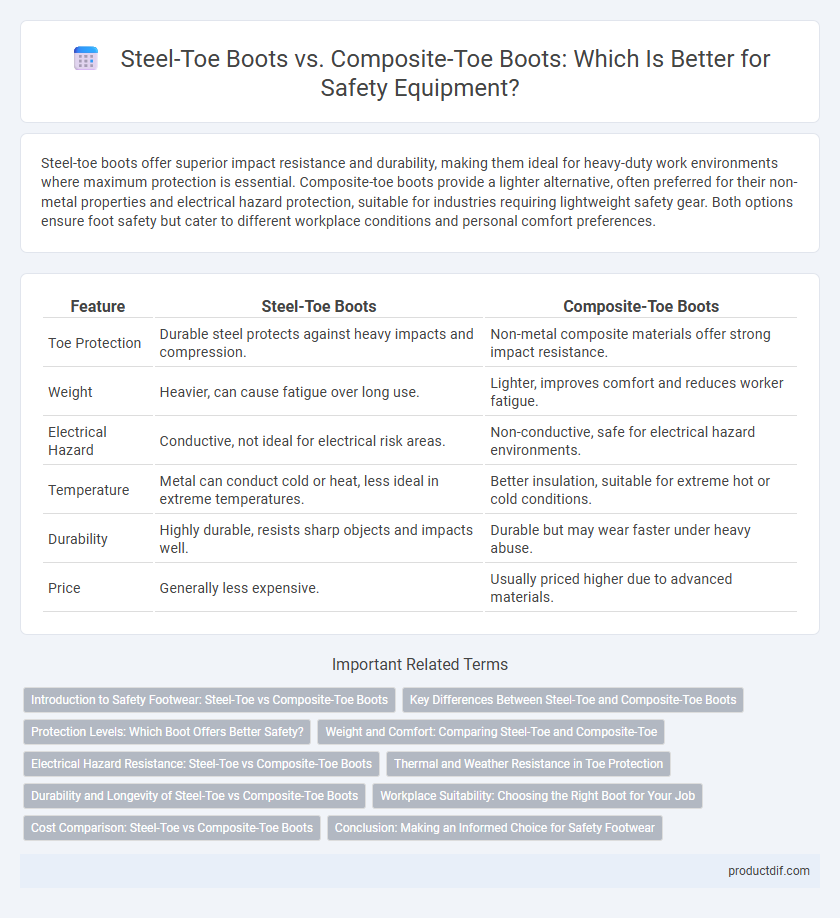

Steel-toe boots offer superior impact resistance and durability, making them ideal for heavy-duty work environments where maximum protection is essential. Composite-toe boots provide a lighter alternative, often preferred for their non-metal properties and electrical hazard protection, suitable for industries requiring lightweight safety gear. Both options ensure foot safety but cater to different workplace conditions and personal comfort preferences.

Table of Comparison

| Feature | Steel-Toe Boots | Composite-Toe Boots |

|---|---|---|

| Toe Protection | Durable steel protects against heavy impacts and compression. | Non-metal composite materials offer strong impact resistance. |

| Weight | Heavier, can cause fatigue over long use. | Lighter, improves comfort and reduces worker fatigue. |

| Electrical Hazard | Conductive, not ideal for electrical risk areas. | Non-conductive, safe for electrical hazard environments. |

| Temperature | Metal can conduct cold or heat, less ideal in extreme temperatures. | Better insulation, suitable for extreme hot or cold conditions. |

| Durability | Highly durable, resists sharp objects and impacts well. | Durable but may wear faster under heavy abuse. |

| Price | Generally less expensive. | Usually priced higher due to advanced materials. |

Introduction to Safety Footwear: Steel-Toe vs Composite-Toe Boots

Steel-toe boots feature a reinforced steel cap that provides superior impact protection and durability, making them ideal for heavy-duty industrial environments. Composite-toe boots use non-metal materials such as Kevlar, carbon fiber, or plastic, offering lightweight comfort and superior electrical hazard protection. Both options meet safety standards like ASTM F2413, but choosing between steel-toe and composite-toe boots depends on workplace-specific hazards and personal comfort preferences.

Key Differences Between Steel-Toe and Composite-Toe Boots

Steel-toe boots feature a metal toe cap that offers superior impact resistance and durability, making them ideal for high-risk environments like construction sites. Composite-toe boots incorporate non-metal materials such as Kevlar, carbon fiber, or plastic, providing lightweight protection and better electrical hazard resistance. Steel-toe boots generally weigh more but provide greater crush protection, while composite-toe boots offer enhanced comfort and compliance with workplaces requiring metal-free footwear.

Protection Levels: Which Boot Offers Better Safety?

Steel-toe boots provide superior impact and compression resistance due to their metal reinforcement, meeting ASTM F2413-18 safety standards for protection against heavy falling objects and sharp hazards. Composite-toe boots, made from non-metal materials like Kevlar or carbon fiber, offer protection that is lighter and non-conductive but may have slightly lower impact resistance than steel. For maximum safety in hazardous environments, steel-toe boots typically offer better protection levels, especially in industries requiring resistance to high-impact and extreme pressure.

Weight and Comfort: Comparing Steel-Toe and Composite-Toe

Steel-toe boots typically weigh more due to their metal reinforcement, which can lead to increased fatigue during long shifts. Composite-toe boots, made from materials like Kevlar or carbon fiber, offer lighter weight and improved comfort without compromising protection. Workers prioritizing agility and extended wear may find composite-toe boots more suitable for their safety footwear needs.

Electrical Hazard Resistance: Steel-Toe vs Composite-Toe Boots

Composite-toe boots offer superior electrical hazard resistance compared to steel-toe boots due to their non-metallic construction, which does not conduct electricity. Steel-toe boots, made with metal components, pose a higher risk of electrical conductivity, making them less suitable for electricians and workers in high-voltage environments. OSHA standards recommend composite-toe footwear for enhanced protection against electrical hazards in workplace settings.

Thermal and Weather Resistance in Toe Protection

Steel-toe boots provide superior impact resistance but tend to conduct heat and cold, potentially causing discomfort in extreme weather conditions. Composite-toe boots offer better thermal insulation due to non-metallic materials, enhancing comfort in both hot and cold environments. Their resistance to temperature fluctuations makes composite-toe boots more suitable for outdoor work in harsh weather, improving overall toe protection.

Durability and Longevity of Steel-Toe vs Composite-Toe Boots

Steel-toe boots exhibit superior durability due to their robust metal reinforcement, making them ideal for harsh industrial environments with heavy impact risks. Composite-toe boots, constructed from materials like Kevlar, carbon fiber, or thermoplastic, offer lighter weight but tend to wear out faster under extreme conditions. Longevity of steel-toe boots often surpasses that of composite-toe boots, especially in high-abrasion settings where metal toes resist crushing and punctures more effectively.

Workplace Suitability: Choosing the Right Boot for Your Job

Steel-toe boots provide exceptional protection in heavy-duty environments such as construction and manufacturing, where impact resistance and durability are critical. Composite-toe boots, lighter and non-metallic, offer better comfort and are ideal for workplaces with metal detection rules or where electrical hazards exist. Selecting the right safety boot depends on specific job hazards, weight considerations, and any workplace safety regulations that dictate toe protection requirements.

Cost Comparison: Steel-Toe vs Composite-Toe Boots

Steel-toe boots typically cost between $80 and $150, offering durability and impact resistance at a lower initial price point compared to composite-toe boots. Composite-toe boots generally range from $100 to $180, featuring lighter materials such as Kevlar or fiberglass that provide similar protection without metal components. Employers and workers often weigh the long-term value of composite toes' electrical hazard protection and lightweight comfort against the upfront savings of steel-toe options.

Conclusion: Making an Informed Choice for Safety Footwear

Steel-toe boots provide superior impact resistance and durability, making them ideal for heavy-duty construction and industrial environments. Composite-toe boots offer a lighter, non-metallic alternative with benefits in electrical hazard environments and metal detector clearance. Choosing between steel-toe and composite-toe boots depends on specific workplace safety requirements, weight preferences, and potential exposure to electrical hazards.

Steel-toe boots vs Composite-toe boots Infographic

productdif.com

productdif.com