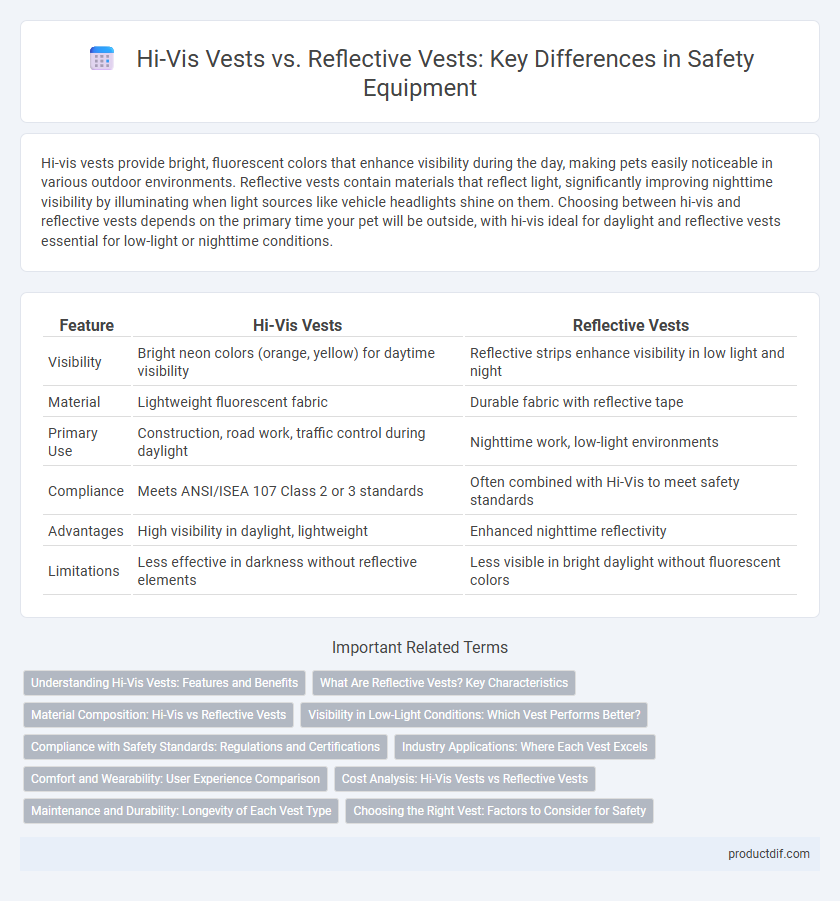

Hi-vis vests provide bright, fluorescent colors that enhance visibility during the day, making pets easily noticeable in various outdoor environments. Reflective vests contain materials that reflect light, significantly improving nighttime visibility by illuminating when light sources like vehicle headlights shine on them. Choosing between hi-vis and reflective vests depends on the primary time your pet will be outside, with hi-vis ideal for daylight and reflective vests essential for low-light or nighttime conditions.

Table of Comparison

| Feature | Hi-Vis Vests | Reflective Vests |

|---|---|---|

| Visibility | Bright neon colors (orange, yellow) for daytime visibility | Reflective strips enhance visibility in low light and night |

| Material | Lightweight fluorescent fabric | Durable fabric with reflective tape |

| Primary Use | Construction, road work, traffic control during daylight | Nighttime work, low-light environments |

| Compliance | Meets ANSI/ISEA 107 Class 2 or 3 standards | Often combined with Hi-Vis to meet safety standards |

| Advantages | High visibility in daylight, lightweight | Enhanced nighttime reflectivity |

| Limitations | Less effective in darkness without reflective elements | Less visible in bright daylight without fluorescent colors |

Understanding Hi-Vis Vests: Features and Benefits

Hi-vis vests are designed with fluorescent materials in colors like neon yellow, orange, or green that increase daytime visibility by absorbing and reflecting light. These vests often include reflective strips that enhance visibility in low-light conditions by reflecting light back toward its source, making workers more noticeable. The combination of bright materials and reflective elements provides superior safety for construction workers, traffic personnel, and emergency responders.

What Are Reflective Vests? Key Characteristics

Reflective vests are safety garments designed with highly visible reflective strips that enhance visibility in low-light or nighttime conditions by reflecting light from headlights or flashlights. Typically made from fluorescent materials in bright colors such as yellow or orange, these vests feature strategically placed reflective tape on the front, back, and shoulders. Essential for roadside workers, construction crews, and emergency responders, reflective vests improve worker safety by increasing visibility to drivers and equipment operators.

Material Composition: Hi-Vis vs Reflective Vests

Hi-vis vests are primarily made from fluorescent polyester fabric that enhances visibility in daylight by absorbing ultraviolet light and re-emitting it as vivid colors, such as neon yellow or orange. Reflective vests incorporate retroreflective materials, typically glass bead or microprismatic tape, sewn onto a polyester base, designed to reflect light back toward its source in low-light or nighttime conditions. The combination of fluorescent fabric in hi-vis vests and reflective components in reflective vests ensures multi-environment visibility for improved safety in various work settings.

Visibility in Low-Light Conditions: Which Vest Performs Better?

Hi-vis vests utilize bright fluorescent colors like neon yellow or orange, enhancing daytime visibility and offering moderate low-light detection, while reflective vests rely on retroreflective materials that bounce light directly back to the source, significantly improving visibility under headlights or flashlights in dark conditions. Studies in occupational safety show that reflective vests outperform hi-vis vests in nighttime or low-light environments due to the specific design that maximizes light reflection. Combining both fluorescent colors and reflective strips offers the best comprehensive visibility across varying light scenarios.

Compliance with Safety Standards: Regulations and Certifications

Hi-vis vests comply with ANSI/ISEA 107 standards, ensuring high visibility in various lighting conditions through fluorescent colors and retroreflective tape. Reflective vests primarily meet EN ISO 20471 certification, focusing on reflectivity for enhanced visibility in low-light environments. Both types of vests are designed to meet specific regulatory requirements to ensure worker safety across different industries and geographic regions.

Industry Applications: Where Each Vest Excels

Hi-vis vests are ideal for construction, roadwork, and warehouse environments where daytime visibility is crucial due to their bright fluorescent colors. Reflective vests excel in low-light or nighttime settings, such as emergency response and traffic control, by enhancing visibility through high-visibility reflective strips. Industries requiring both day and night safety often combine hi-vis colors with reflective materials for maximum protection.

Comfort and Wearability: User Experience Comparison

Hi-vis vests typically feature lightweight, breathable materials that enhance comfort during extended wear, making them suitable for hot or humid conditions. Reflective vests often prioritize visibility with reflective strips but may use less breathable fabrics, potentially causing discomfort in warm environments. User experience favors hi-vis vests for prolonged tasks requiring both safety and comfort, while reflective vests excel in low-light visibility but may compromise wearability in heat.

Cost Analysis: Hi-Vis Vests vs Reflective Vests

Hi-vis vests generally offer a lower upfront cost compared to reflective vests, making them a budget-friendly option for many industries. Reflective vests, while typically more expensive, provide enhanced visibility during low-light conditions, potentially reducing accident-related expenses. Evaluating long-term safety benefits against initial expenses is crucial for businesses aiming to balance cost efficiency with worker protection.

Maintenance and Durability: Longevity of Each Vest Type

Hi-vis vests are designed with fluorescent materials that maintain high visibility during daylight and require minimal maintenance, as their bright colors fade slowly over time with regular washing. Reflective vests rely on retroreflective strips that can degrade or peel after repeated exposure to harsh weather and frequent laundering, demanding careful cleaning to preserve reflectivity. Hi-vis vests generally offer longer durability for daily use, while reflective vests may need more frequent replacement or repairs to maintain optimal safety performance.

Choosing the Right Vest: Factors to Consider for Safety

Choosing the right safety vest depends on the work environment and visibility needs; hi-vis vests use fluorescent colors like neon yellow or orange to enhance daytime visibility, while reflective vests incorporate reflective tape for improved visibility in low-light or nighttime conditions. Material durability, comfort, and compliance with industry safety standards such as ANSI/ISEA 107 are critical factors that influence vest selection. Proper vest choice ensures maximum worker visibility, reducing accident risks in construction, roadwork, and industrial settings.

Hi-vis vests vs Reflective vests Infographic

productdif.com

productdif.com