Cut-resistant gloves provide essential protection by preventing injuries from sharp objects such as glass or metal, making them ideal for handling rough materials. Needle-resistant gloves are specifically designed to guard against punctures and infections caused by needles, which is crucial for medical or veterinary settings. Choosing between the two depends on the nature of the hazard, ensuring optimal safety for activities involving pets.

Table of Comparison

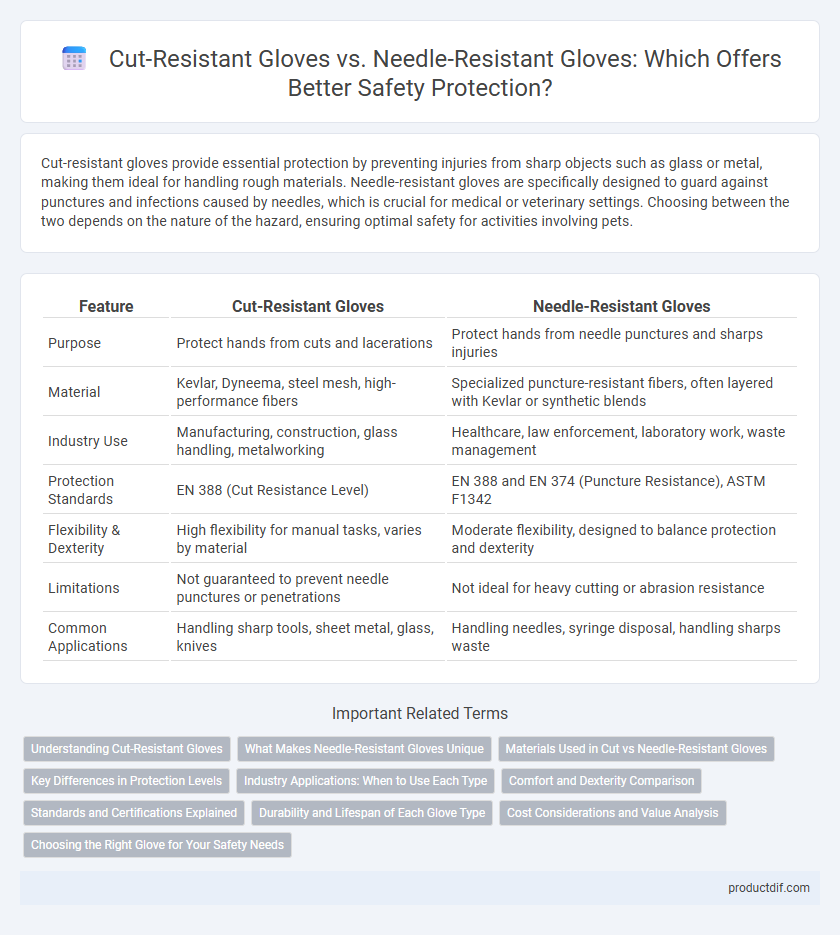

| Feature | Cut-Resistant Gloves | Needle-Resistant Gloves |

|---|---|---|

| Purpose | Protect hands from cuts and lacerations | Protect hands from needle punctures and sharps injuries |

| Material | Kevlar, Dyneema, steel mesh, high-performance fibers | Specialized puncture-resistant fibers, often layered with Kevlar or synthetic blends |

| Industry Use | Manufacturing, construction, glass handling, metalworking | Healthcare, law enforcement, laboratory work, waste management |

| Protection Standards | EN 388 (Cut Resistance Level) | EN 388 and EN 374 (Puncture Resistance), ASTM F1342 |

| Flexibility & Dexterity | High flexibility for manual tasks, varies by material | Moderate flexibility, designed to balance protection and dexterity |

| Limitations | Not guaranteed to prevent needle punctures or penetrations | Not ideal for heavy cutting or abrasion resistance |

| Common Applications | Handling sharp tools, sheet metal, glass, knives | Handling needles, syringe disposal, handling sharps waste |

Understanding Cut-Resistant Gloves

Cut-resistant gloves are specifically designed with materials like Kevlar, Dyneema, or high-performance polyethylene to provide protection against sharp objects and blade injuries in industrial, construction, and manufacturing settings. These gloves offer varying levels of cut resistance measured by standards such as ANSI/ISEA or EN 388, ensuring workers select appropriate protection based on the risk level. Understanding the material composition and cut resistance ratings is crucial for optimizing hand safety and preventing workplace accidents involving slashing hazards.

What Makes Needle-Resistant Gloves Unique

Needle-resistant gloves are uniquely engineered with specialized materials like Kevlar or steel mesh to prevent penetration from sharp needles, offering critical protection in medical and laboratory environments. Their design focuses on minimizing the risk of needlestick injuries, which are distinct from the slicing hazards addressed by cut-resistant gloves. These gloves often incorporate tighter knit patterns and enhanced puncture resistance while maintaining dexterity for precision tasks.

Materials Used in Cut vs Needle-Resistant Gloves

Cut-resistant gloves commonly utilize high-performance materials such as Kevlar, Dyneema, or stainless steel fibers, providing superior protection against sharp objects and slashes. Needle-resistant gloves often incorporate specialized tightly woven materials like nitrile-coated fabrics or dense polyethylene blends designed to prevent punctures from fine needles. The difference in material composition directly correlates to their specific protective functions, with cut-resistant gloves emphasizing abrasion resistance and needle-resistant gloves focusing on puncture prevention.

Key Differences in Protection Levels

Cut-resistant gloves are engineered with high-performance fibers such as Kevlar or Dyneema to provide superior protection against sharp blades and slicing hazards, typically measured by ANSI/ISEA cut resistance levels. Needle-resistant gloves, often made with densely woven stainless steel or specialized synthetic fibers, offer enhanced protection against punctures and needlestick injuries, crucial in medical and laboratory environments. The key difference lies in their specific protective function: cut-resistant gloves prevent lacerations, while needle-resistant gloves prevent penetration from sharp, pointed objects.

Industry Applications: When to Use Each Type

Cut-resistant gloves are essential in industries such as construction, manufacturing, and metalworking where workers regularly handle sharp tools or materials prone to causing cuts and lacerations. Needle-resistant gloves are specifically designed for medical and laboratory environments where protection against punctures from needles, sharps, and contaminated instruments is critical. Selecting the appropriate glove type depends on the nature of hazards: cut-resistant gloves for slicing risks, and needle-resistant gloves for puncture and contamination prevention.

Comfort and Dexterity Comparison

Cut-resistant gloves typically offer greater flexibility and breathability, enhancing comfort and dexterity for tasks requiring fine motor skills. Needle-resistant gloves, reinforced with denser materials for puncture protection, may feel stiffer and less breathable, potentially reducing tactile sensitivity. Selecting gloves depends on balancing protection needs with the ergonomic benefits essential for prolonged wear and precision work.

Standards and Certifications Explained

Cut-resistant gloves are commonly certified under standards such as ANSI/ISEA 105 and EN 388, which measure the glove's ability to resist blade cuts and abrasions, ensuring protection in industries like manufacturing and construction. Needle-resistant gloves adhere to standards like ASTM F2878 and EN 10819, which specifically test for puncture resistance against hypodermic needles, critical for healthcare and laboratory environments. Understanding these certifications helps in selecting the appropriate glove type based on specific hazard assessments and compliance requirements.

Durability and Lifespan of Each Glove Type

Cut-resistant gloves are typically made from high-performance fibers like Kevlar or Dyneema, providing excellent durability and a longer lifespan under mechanical stress. Needle-resistant gloves incorporate specialized materials such as stainless steel mesh or tightly woven fibers designed to prevent punctures, but their lifespan may be shorter due to degradation from repeated needle penetration. When choosing between the two, consider the specific hazards; cut-resistant gloves excel in abrasion and cut resistance with extended use, while needle-resistant gloves may require more frequent replacement to maintain optimal protection.

Cost Considerations and Value Analysis

Cut-resistant gloves typically cost less than needle-resistant gloves due to simpler material composition and manufacturing processes, offering reliable protection against sharp objects like knives and glass. Needle-resistant gloves involve advanced fibers such as Kevlar or steel mesh, increasing price but providing essential defense against puncture wounds in medical and laboratory environments. Analyzing value requires assessing workplace risks and balancing upfront investment with potential injury reduction, where selecting the appropriate glove type enhances both safety and cost-efficiency.

Choosing the Right Glove for Your Safety Needs

Cut-resistant gloves provide robust protection against sharp blades and tools, making them essential for tasks involving knives or glass handling. Needle-resistant gloves are specially designed to prevent punctures from needles and other sharps, ideal for healthcare and laboratory environments. Selecting the right glove depends on the specific hazards faced, ensuring maximum safety by matching glove material and resistance levels to the job requirements.

Cut-resistant gloves vs Needle-resistant gloves Infographic

productdif.com

productdif.com