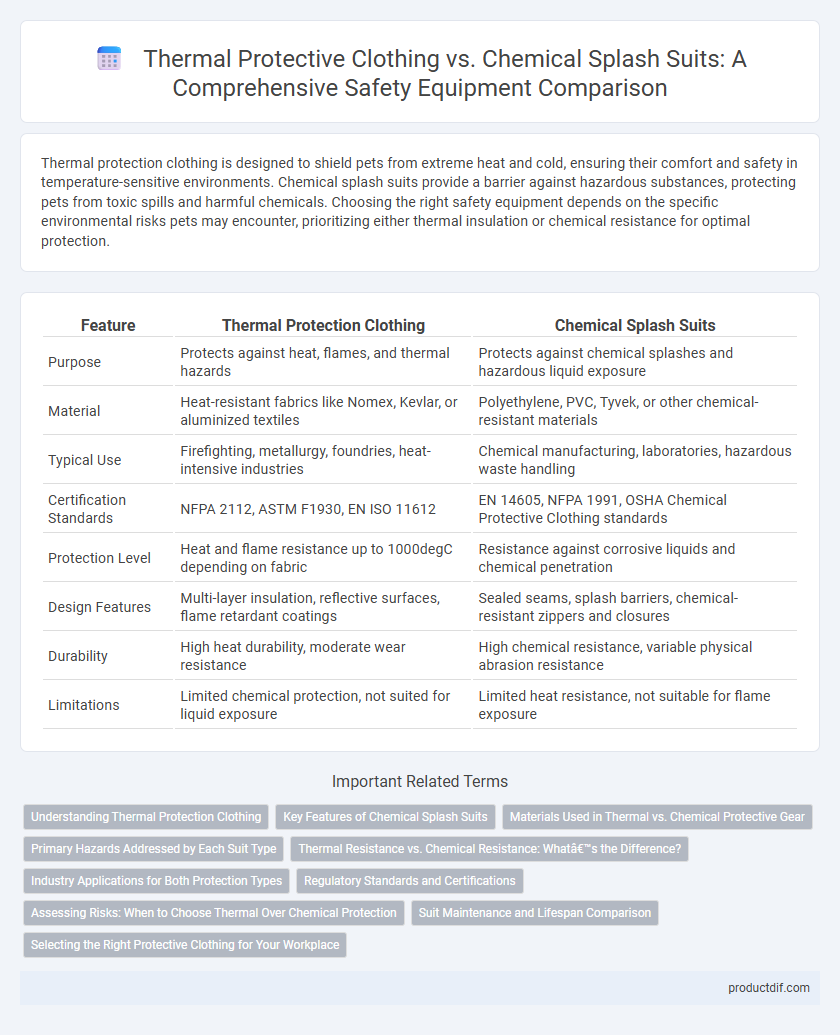

Thermal protection clothing is designed to shield pets from extreme heat and cold, ensuring their comfort and safety in temperature-sensitive environments. Chemical splash suits provide a barrier against hazardous substances, protecting pets from toxic spills and harmful chemicals. Choosing the right safety equipment depends on the specific environmental risks pets may encounter, prioritizing either thermal insulation or chemical resistance for optimal protection.

Table of Comparison

| Feature | Thermal Protection Clothing | Chemical Splash Suits |

|---|---|---|

| Purpose | Protects against heat, flames, and thermal hazards | Protects against chemical splashes and hazardous liquid exposure |

| Material | Heat-resistant fabrics like Nomex, Kevlar, or aluminized textiles | Polyethylene, PVC, Tyvek, or other chemical-resistant materials |

| Typical Use | Firefighting, metallurgy, foundries, heat-intensive industries | Chemical manufacturing, laboratories, hazardous waste handling |

| Certification Standards | NFPA 2112, ASTM F1930, EN ISO 11612 | EN 14605, NFPA 1991, OSHA Chemical Protective Clothing standards |

| Protection Level | Heat and flame resistance up to 1000degC depending on fabric | Resistance against corrosive liquids and chemical penetration |

| Design Features | Multi-layer insulation, reflective surfaces, flame retardant coatings | Sealed seams, splash barriers, chemical-resistant zippers and closures |

| Durability | High heat durability, moderate wear resistance | High chemical resistance, variable physical abrasion resistance |

| Limitations | Limited chemical protection, not suited for liquid exposure | Limited heat resistance, not suitable for flame exposure |

Understanding Thermal Protection Clothing

Thermal protection clothing is designed to shield workers from extreme heat and flame exposure, using materials like aramid fibers and aluminized fabrics that reflect radiant heat. These garments provide insulation and prevent thermal burns by trapping air and resisting high temperatures, essential in industries such as firefighting and metalworking. Unlike chemical splash suits, which protect against hazardous liquid chemicals, thermal protection clothing prioritizes heat resistance and flame retardancy for effective personal safety.

Key Features of Chemical Splash Suits

Chemical splash suits are designed with high-resistance materials such as PVC or neoprene that provide effective protection against hazardous liquid chemicals. They feature sealed seams and secure closures, including elastic cuffs and storm flaps, to prevent chemical penetration and ensure a tight barrier. These suits often include integrated hoods and boot covers, enhancing full-body protection in environments with potential chemical splashes.

Materials Used in Thermal vs. Chemical Protective Gear

Thermal protection clothing typically utilizes materials like aluminized fabrics, aramids (e.g., Nomex, Kevlar), and fiberglass to resist high heat and flames, while chemical splash suits are often constructed from polyethylene, neoprene, or PVC laminates designed to prevent chemical permeation and corrosion. Thermal gear prioritizes insulation and flame resistance, employing multilayered composites to dissipate heat, whereas chemical suits focus on barrier integrity and resistance to specific hazardous substances. The choice of materials directly impacts the suit's effectiveness in protecting against thermal hazards or chemical exposures in industrial or emergency response settings.

Primary Hazards Addressed by Each Suit Type

Thermal protection clothing primarily safeguards against extreme heat, flames, and thermal radiation, making it essential for firefighters and workers exposed to high-temperature environments. Chemical splash suits provide a barrier against hazardous chemical spills, splashes, and airborne toxic substances, crucial for handling acids, solvents, and corrosive agents. Both suit types are engineered to prevent specific occupational injuries, with thermal suits focusing on burn prevention and chemical suits on chemical exposure containment.

Thermal Resistance vs. Chemical Resistance: What’s the Difference?

Thermal protection clothing is designed to provide high thermal resistance, shielding wearers from extreme heat, flames, and radiant energy commonly encountered in firefighting and industrial settings. Chemical splash suits prioritize chemical resistance, preventing harmful substances such as acids, bases, and solvents from penetrating the fabric and causing skin damage. Understanding the difference ensures the appropriate selection of protective gear based on exposure risks, maximizing safety in hazardous environments.

Industry Applications for Both Protection Types

Thermal protection clothing is essential in industries such as firefighting, metal forging, and glass manufacturing where exposure to high heat and flames poses significant risks. Chemical splash suits are primarily used in chemical processing plants, pharmaceuticals, and hazardous waste management to guard workers against harmful chemical splashes and spills. Both protection types are critical in environments demanding strict safety protocols to prevent injury and comply with occupational safety regulations.

Regulatory Standards and Certifications

Thermal protection clothing complies with standards such as NFPA 2112 and EN ISO 11612, which ensure resistance to heat and flame exposure in industrial settings. Chemical splash suits adhere to regulations like EN 14605 and OSHA 1910.120, providing barriers against hazardous liquid chemicals and minimizing skin contact risks. Both types require certification through rigorous testing to verify compliance and worker safety in specialized environments.

Assessing Risks: When to Choose Thermal Over Chemical Protection

Thermal protection clothing is essential for environments with extreme heat exposure, such as foundries or firefighting scenarios, because it insulates against high temperatures and radiant heat. Chemical splash suits are designed for hazardous material handling, providing impermeable barriers against corrosive substances and toxic chemicals. When assessing risks, prioritize thermal protection suits for flame or heat hazards, while selecting chemical splash suits for exposure to liquid chemicals or toxic splashes.

Suit Maintenance and Lifespan Comparison

Thermal protection clothing requires regular inspection for insulation integrity and heat-resistant coating to maintain its protective performance, typically offering a lifespan of 3 to 5 years depending on usage and exposure. Chemical splash suits demand thorough cleaning after each exposure to hazardous substances and frequent checks for punctures or fabric degradation, with an average lifespan ranging from 1 to 3 years due to chemical wear. Proper maintenance protocols significantly extend the functional life of both suit types, ensuring continuous safety against thermal and chemical hazards.

Selecting the Right Protective Clothing for Your Workplace

Selecting the right protective clothing for your workplace depends on identifying specific hazards, such as extreme heat or chemical exposure. Thermal protection clothing is designed to shield workers from high temperatures and thermal hazards, using materials that resist flames and radiant heat. Chemical splash suits provide impermeable barriers against hazardous liquids and corrosive substances, ensuring worker safety in chemical handling environments.

Thermal protection clothing vs Chemical splash suits Infographic

productdif.com

productdif.com