Arc flash suits provide specialized protection against electrical hazards by combining insulating and flame-resistant materials designed to withstand high-temperature flashes, while fire-retardant coveralls primarily protect against flames and heat but may not offer adequate insulation from electrical arcs. Choosing between the two depends on the specific industrial environment and risk assessments, with arc flash suits being essential for electrical work involving live circuits. Fire-retardant coveralls are more suitable for general flame exposure, offering comfort and flexibility without the heavy insulation requirements of arc flash gear.

Table of Comparison

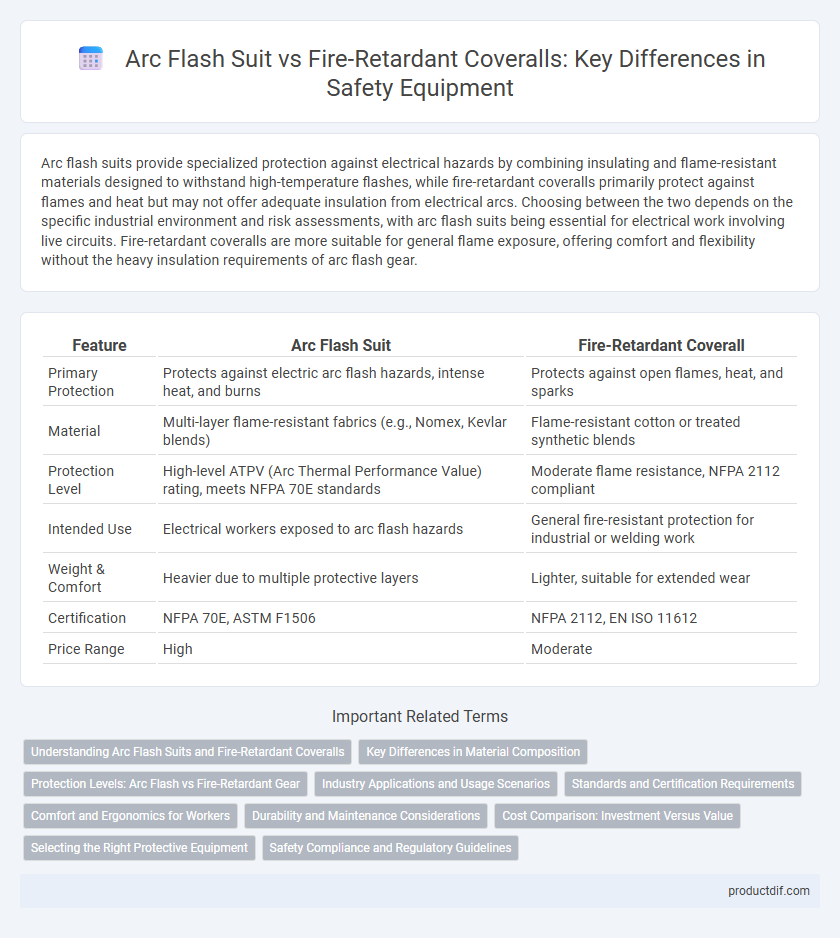

| Feature | Arc Flash Suit | Fire-Retardant Coverall |

|---|---|---|

| Primary Protection | Protects against electric arc flash hazards, intense heat, and burns | Protects against open flames, heat, and sparks |

| Material | Multi-layer flame-resistant fabrics (e.g., Nomex, Kevlar blends) | Flame-resistant cotton or treated synthetic blends |

| Protection Level | High-level ATPV (Arc Thermal Performance Value) rating, meets NFPA 70E standards | Moderate flame resistance, NFPA 2112 compliant |

| Intended Use | Electrical workers exposed to arc flash hazards | General fire-resistant protection for industrial or welding work |

| Weight & Comfort | Heavier due to multiple protective layers | Lighter, suitable for extended wear |

| Certification | NFPA 70E, ASTM F1506 | NFPA 2112, EN ISO 11612 |

| Price Range | High | Moderate |

Understanding Arc Flash Suits and Fire-Retardant Coveralls

Arc flash suits provide specialized protection against high-temperature electrical flashes by combining flame-resistant materials with thermal insulation to withstand intense heat and pressure. Fire-retardant coveralls offer a broader range of protection against flames and heat in industrial environments but lack the comprehensive thermal and electrical defense integral to arc flash suits. Selecting the appropriate safety equipment depends on exposure risk, with arc flash suits essential for electrical workers facing potential arc flash incidents and fire-retardant coveralls suitable for general fire hazard environments.

Key Differences in Material Composition

Arc flash suits are made from specialized flame-resistant fabrics such as Nomex, Kevlar, or a blend of both, designed to withstand intense heat and electrical arcs. Fire-retardant coveralls typically use treated cotton or other flame-resistant materials that provide basic protection against flames but may not endure the high thermal stresses of arc flashes. The key material distinction lies in the enhanced thermal resistance and electrical insulation properties of arc flash suit fabrics compared to the more general flame resistance of fire-retardant coveralls.

Protection Levels: Arc Flash vs Fire-Retardant Gear

Arc flash suits provide specialized protection designed to withstand high thermal energy levels generated during electrical arc flash events, rated according to ATPV (Arc Thermal Performance Value) or EBT (Energy Breakopen Threshold) standards. Fire-retardant coveralls offer flame resistance by slowing ignition and self-extinguishing, typically meeting ASTM F1506 or NFPA 2112 standards, but do not provide the same thermal protection against arc flash incidents. Selecting the appropriate safety equipment depends on the specific hazard exposure, with arc flash suits essential for environments with electrical flash risks and fire-retardant coveralls suited for general flame resistance.

Industry Applications and Usage Scenarios

Arc flash suits are specifically designed for high-voltage electrical work environments such as utilities, electrical substations, and manufacturing plants where arc flash hazards are prevalent. Fire-retardant coveralls are commonly used in industries like oil and gas, petrochemical, and welding operations to provide basic flame resistance against incidental exposure to flames and heat. While arc flash suits offer specialized protection against intense arc flash energy, fire-retardant coveralls are preferred for general fire safety in environments with lower risk of electrical incidents.

Standards and Certification Requirements

Arc flash suits must comply with NFPA 70E and ASTM F1506 standards, ensuring protection against electrical arc hazards with specific ATPV (Arc Thermal Performance Value) ratings. Fire-retardant coveralls are certified under NFPA 2112 and ISO 11612, focusing on resistance to flash fire and heat exposure. Both types require rigorous testing for flame resistance, but arc flash suits demand higher electrical insulation and thermal protection certification.

Comfort and Ergonomics for Workers

Arc flash suits, designed with multiple layers and heavy insulation, often weigh more and restrict movement, potentially causing discomfort during prolonged wear. Fire-retardant coveralls are typically lighter and offer greater flexibility, enhancing worker mobility and reducing fatigue in hot environments. Choosing the right safety gear balances protection with ergonomic design to maintain comfort without compromising safety standards.

Durability and Maintenance Considerations

Arc flash suits are constructed with heavy-duty, multi-layer materials designed to withstand high-temperature exposure and electrical hazards, offering superior durability compared to fire-retardant coveralls. Fire-retardant coveralls typically require routine laundering with specialized detergents to maintain flame-resistant properties, while arc flash suits demand more complex maintenance, including regular inspections for material integrity and potential damage. The higher upfront and upkeep costs of arc flash suits are offset by their enhanced protection and longer service life in extreme environments.

Cost Comparison: Investment Versus Value

Arc flash suits typically require a higher initial investment due to advanced materials and specialized design for extreme electrical hazard protection. Fire-retardant coveralls offer a cost-effective solution with lower upfront costs but may require more frequent replacement to maintain safety standards. Evaluating the total cost of ownership involves balancing the protection level against durability and compliance with industry safety regulations.

Selecting the Right Protective Equipment

Arc flash suits provide extensive protection against electrical hazards, offering high-rated arc flash resistance essential for workers in environments with potential electrical explosions. Fire-retardant coveralls deliver reliable protection against flames and heat but typically lack the specialized insulation and durability needed for arc flash scenarios. Selecting the right protective equipment requires evaluating the specific hazard level, ensuring compliance with NFPA 70E standards, and prioritizing gear rated appropriately for the anticipated risk.

Safety Compliance and Regulatory Guidelines

Arc flash suits are specifically designed to meet NFPA 70E standards, providing high-level protection against electrical arc flash hazards and ensuring compliance with OSHA regulations. Fire-retardant coveralls comply with ASTM F1506 requirements, offering flame resistance primarily for general fire exposure but not sufficient for arc flash events. Selecting the appropriate safety equipment based on regulatory guidelines is critical to mitigate workplace risks and maintain compliance with industry safety standards.

Arc flash suit vs Fire-retardant coverall Infographic

productdif.com

productdif.com