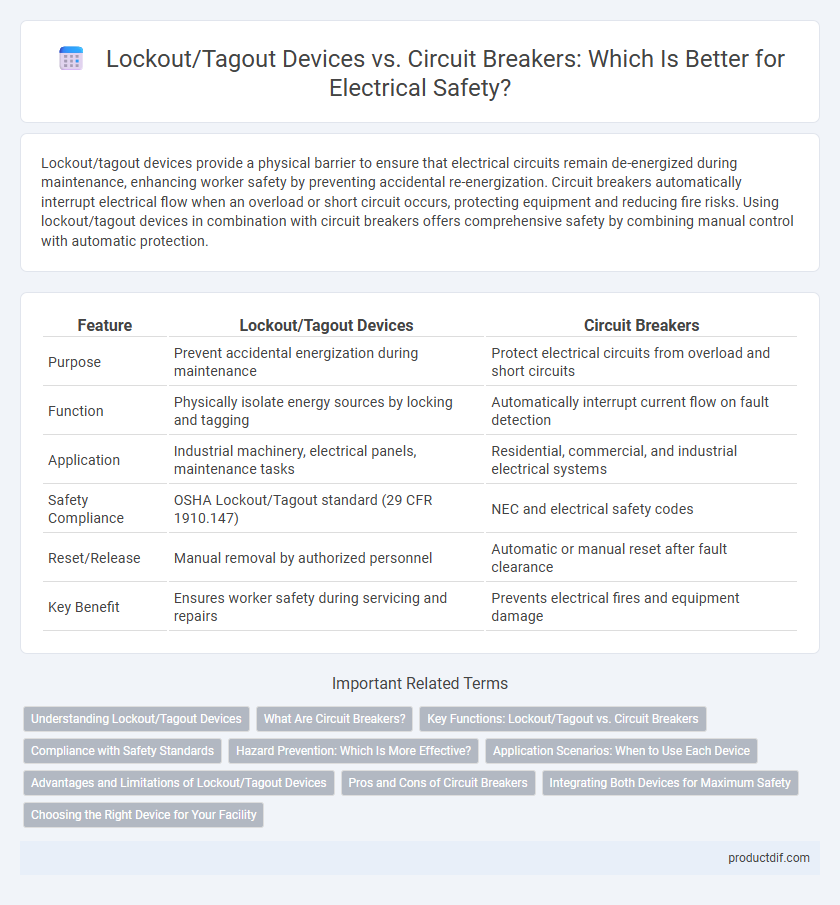

Lockout/tagout devices provide a physical barrier to ensure that electrical circuits remain de-energized during maintenance, enhancing worker safety by preventing accidental re-energization. Circuit breakers automatically interrupt electrical flow when an overload or short circuit occurs, protecting equipment and reducing fire risks. Using lockout/tagout devices in combination with circuit breakers offers comprehensive safety by combining manual control with automatic protection.

Table of Comparison

| Feature | Lockout/Tagout Devices | Circuit Breakers |

|---|---|---|

| Purpose | Prevent accidental energization during maintenance | Protect electrical circuits from overload and short circuits |

| Function | Physically isolate energy sources by locking and tagging | Automatically interrupt current flow on fault detection |

| Application | Industrial machinery, electrical panels, maintenance tasks | Residential, commercial, and industrial electrical systems |

| Safety Compliance | OSHA Lockout/Tagout standard (29 CFR 1910.147) | NEC and electrical safety codes |

| Reset/Release | Manual removal by authorized personnel | Automatic or manual reset after fault clearance |

| Key Benefit | Ensures worker safety during servicing and repairs | Prevents electrical fires and equipment damage |

Understanding Lockout/Tagout Devices

Lockout/tagout devices are essential safety mechanisms designed to isolate energy sources during equipment maintenance, preventing accidental startup and ensuring worker protection. Unlike circuit breakers, which primarily interrupt electrical flow, lockout/tagout devices physically secure switches or valves, providing a visible and reliable indication that equipment must not be energized. Proper implementation of lockout/tagout procedures reduces workplace injuries by controlling hazardous energy during servicing activities.

What Are Circuit Breakers?

Circuit breakers are automatic electrical switches designed to protect an electrical circuit from damage caused by overload or short circuit by interrupting the current flow. Unlike lockout/tagout devices used primarily for isolating and securing equipment during maintenance, circuit breakers reset automatically or manually to restore normal operation. They play a critical role in electrical safety by preventing electrical fires and equipment damage through timely disruption of hazardous electrical faults.

Key Functions: Lockout/Tagout vs. Circuit Breakers

Lockout/tagout devices provide physical isolation and control of energy sources by preventing equipment from being energized during maintenance, ensuring worker safety through padlocks and tagged warnings. Circuit breakers automatically interrupt electrical flow in case of overloads or short circuits, protecting equipment and personnel from electrical hazards. While lockout/tagout devices focus on procedural safety by securing energy isolation points, circuit breakers offer real-time electrical protection by detecting and stopping fault currents.

Compliance with Safety Standards

Lockout/tagout devices comply with OSHA standard 29 CFR 1910.147, ensuring the proper isolation of hazardous energy during maintenance to prevent accidental startup. Circuit breakers meet ANSI/IEEE standards for electrical protection but do not provide fail-safe physical isolation for workers servicing equipment. Compliance with safety regulations mandates using lockout/tagout procedures alongside circuit breakers for effective hazardous energy control.

Hazard Prevention: Which Is More Effective?

Lockout/tagout devices provide more effective hazard prevention by physically isolating energy sources during maintenance, ensuring machines cannot be accidentally energized. Circuit breakers offer rapid interruption of electrical flow but do not prevent accidental re-energization or machine startup. For comprehensive safety, lockout/tagout procedures minimize risks associated with unexpected energization better than circuit breakers alone.

Application Scenarios: When to Use Each Device

Lockout/tagout devices are essential for ensuring worker safety during maintenance by physically securing energy sources and preventing accidental machine startup in industrial settings. Circuit breakers provide automated electrical protection by interrupting current flow during overloads or short circuits, making them suitable for protecting electrical circuits in everyday operation. Use lockout/tagout procedures when performing repairs or servicing equipment, while circuit breakers function continuously to protect electrical systems from damage and fire hazards.

Advantages and Limitations of Lockout/Tagout Devices

Lockout/tagout devices provide a physical barrier that ensures machinery remains de-energized during maintenance, significantly reducing the risk of accidental startup and electrical hazards. These devices offer greater control and accountability by requiring authorized personnel to apply individual locks or tags, which circuit breakers alone cannot guarantee. However, lockout/tagout procedures can be time-consuming to implement and rely heavily on strict compliance and training to be effective, limiting their practicality in fast-paced or emergency environments.

Pros and Cons of Circuit Breakers

Circuit breakers offer quick and automatic electrical shutdown, which enhances safety by preventing overloads and short circuits. Their main advantage lies in easy resetting without replacing components, reducing downtime, but they can be less reliable as a lockout/tagout method since they do not provide a physical lock to prevent accidental re-energization. Electrical safety protocols must consider that, unlike lockout/tagout devices designed to secure equipment during maintenance, circuit breakers primarily protect circuits rather than ensure worker safety during repairs.

Integrating Both Devices for Maximum Safety

Integrating lockout/tagout devices with circuit breakers enhances workplace safety by ensuring both physical disconnection and clear identification of inoperative circuits. Lockout/tagout devices prevent accidental energization during maintenance, while circuit breakers provide automatic overload protection and fault interruption. Combining these devices creates a comprehensive safety system that minimizes electrical hazards and ensures compliance with OSHA regulations.

Choosing the Right Device for Your Facility

Lockout/tagout devices provide a more secure and visible means of isolating energy sources during maintenance, preventing accidental equipment startup and enhancing worker safety. Circuit breakers offer automatic protection by interrupting electrical flow during overloads or short circuits but lack the physical lockout capability necessary for comprehensive safety compliance. Selecting the right device depends on the facility's specific operational hazards and regulatory requirements, with lockout/tagout devices preferred for maintenance safety and circuit breakers essential for routine electrical protection.

Lockout/tagout devices vs Circuit breakers Infographic

productdif.com

productdif.com