Confined space harnesses are specifically designed for rescue and work in tight, enclosed areas, offering enhanced safety features such as multiple attachment points and reinforced materials to prevent accidents. Standard harnesses are typically used for general pet restraint, lacking the specialized support and durability required for confined space scenarios. Choosing a confined space harness ensures maximum protection and compliance with safety regulations when pets are in high-risk environments.

Table of Comparison

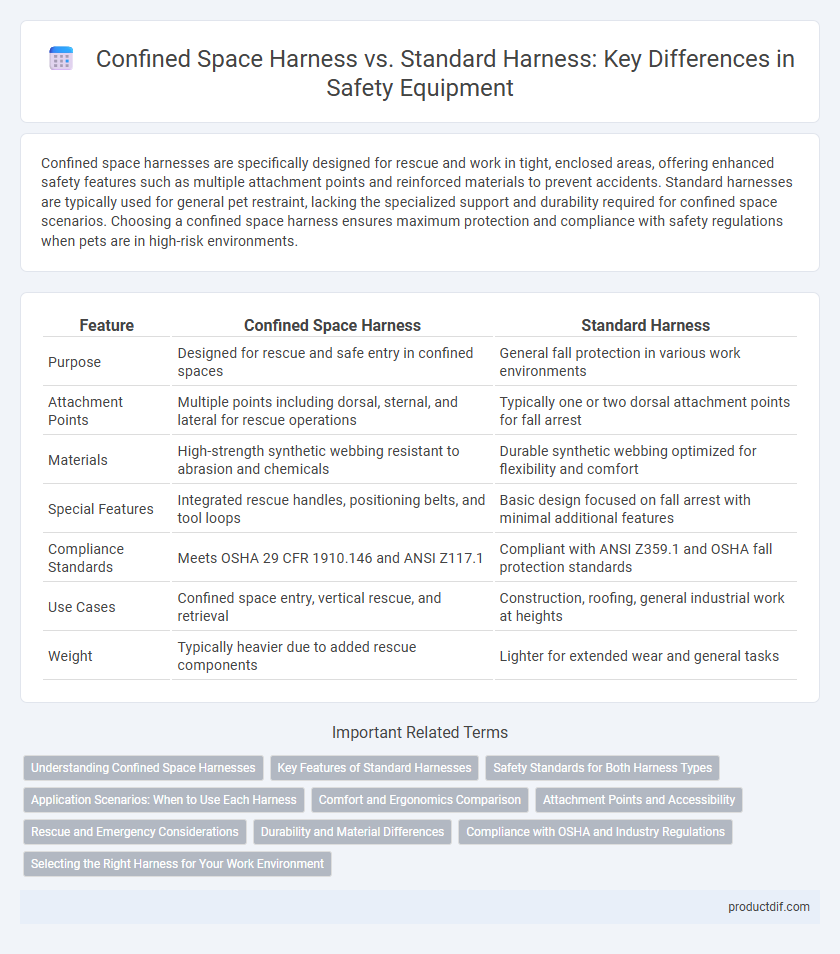

| Feature | Confined Space Harness | Standard Harness |

|---|---|---|

| Purpose | Designed for rescue and safe entry in confined spaces | General fall protection in various work environments |

| Attachment Points | Multiple points including dorsal, sternal, and lateral for rescue operations | Typically one or two dorsal attachment points for fall arrest |

| Materials | High-strength synthetic webbing resistant to abrasion and chemicals | Durable synthetic webbing optimized for flexibility and comfort |

| Special Features | Integrated rescue handles, positioning belts, and tool loops | Basic design focused on fall arrest with minimal additional features |

| Compliance Standards | Meets OSHA 29 CFR 1910.146 and ANSI Z117.1 | Compliant with ANSI Z359.1 and OSHA fall protection standards |

| Use Cases | Confined space entry, vertical rescue, and retrieval | Construction, roofing, general industrial work at heights |

| Weight | Typically heavier due to added rescue components | Lighter for extended wear and general tasks |

Understanding Confined Space Harnesses

Confined space harnesses are specifically designed for safe entry and exit in tight, restricted environments, featuring attachment points for vertical and horizontal lifelines, as well as fall arrest and retrieval systems. Unlike standard harnesses, confined space harnesses include reinforced D-rings, extra padding, and adjustable straps to ensure mobility and comfort during confined operations. Proper use of confined space harnesses enhances worker safety by enabling efficient rescue and minimizing risks associated with limited space and hazardous atmospheres.

Key Features of Standard Harnesses

Standard harnesses offer a versatile design with adjustable straps, padded shoulder and leg loops for enhanced comfort, and durable materials such as nylon webbing to ensure strength and longevity. These harnesses often include multiple attachment points for versatility in fall protection and rescue scenarios. Their ergonomic construction supports a wide range of work environments but lacks the specialized ventilation and attachment options found in confined space harnesses.

Safety Standards for Both Harness Types

Confined space harnesses comply with rigorous safety standards such as ANSI/ASSE Z359.1 and OSHA 1910.146, ensuring enhanced fall protection and secure attachment points for rescue scenarios. Standard harnesses typically meet general fall protection standards like ANSI Z359.11, designed primarily for ladder climbing and construction work without specialized confined space features. Both harness types undergo strict testing for load capacity, durability, and resistance to environmental hazards to maximize worker safety.

Application Scenarios: When to Use Each Harness

Confined space harnesses are essential for environments with limited entry and exit points, such as tanks, tunnels, or underground vaults, providing secure attachment for rescue and fall arrest systems. Standard harnesses are suited for general fall protection in construction, roofing, and industrial maintenance where vertical mobility and rescue retrieval are less constrained. Choosing the correct harness depends on the specific spatial limitations and rescue requirements of the worksite to ensure maximum safety and compliance with OSHA and ANSI standards.

Comfort and Ergonomics Comparison

Confined space harnesses prioritize ergonomic fit and enhanced comfort designed for restricted environments, featuring adjustable straps and padding that reduce pressure points during prolonged use. Standard harnesses offer a more general fit, often lacking the specialized contours and breathability necessary for confined spaces, which can lead to discomfort and reduced mobility. The tailored design of confined space harnesses improves user posture and minimizes fatigue, making them more suitable for demanding safety applications.

Attachment Points and Accessibility

Confined space harnesses feature multiple attachment points designed for 360-degree mobility and secure positioning in tight environments, unlike standard harnesses that typically offer fewer, less strategically placed connection options. The enhanced accessibility in confined space harnesses enables safer maneuvering and efficient rescue operations, critical in restricted or hazardous areas. Standard harnesses prioritize general fall protection but lack the specialized attachment versatility essential for confined space entry and work.

Rescue and Emergency Considerations

Confined space harnesses feature specialized attachment points and padding to facilitate quick and secure rescues in tight or hazardous environments, while standard harnesses often lack these critical emergency-specific designs. The enhanced durability and positioning of confined space harnesses optimize worker safety by enabling efficient lift and retrieval during emergencies. Choosing a confined space harness significantly improves rescue response time and reduces risk in emergency scenarios compared to standard harnesses.

Durability and Material Differences

Confined space harnesses are typically constructed with heavier-duty materials such as high-strength polyester or nylon webbing, designed to withstand harsh environments and prolonged exposure to chemicals and abrasion. Standard harnesses often use lighter materials suitable for general fall protection but may lack the reinforced stitching and corrosion-resistant hardware found in confined space models. The increased durability of confined space harnesses ensures reliable performance in demanding conditions, enhancing safety for workers operating in restricted or hazardous areas.

Compliance with OSHA and Industry Regulations

Confined space harnesses are specifically designed to meet OSHA regulations 1910.146, ensuring worker safety in hazardous environments by incorporating fall arrest and retrieval systems. Standard harnesses comply with ANSI Z359 standards but may lack features critical for confined space entry, such as adjustable suspension trauma straps and reinforced attachment points. Selecting a confined space harness guarantees adherence to both OSHA requirements and industry best practices for confined space safety.

Selecting the Right Harness for Your Work Environment

Confined space harnesses are designed with specialized features such as adjustable positioning straps, reinforced attachment points, and fall arrest capabilities tailored for restricted and hazardous environments. Standard harnesses offer general support and comfort but lack the enhanced safety mechanisms crucial for confined space entry and rescue operations. Choosing the appropriate harness depends on factors like work environment, regulatory compliance, and specific safety requirements to ensure maximum protection and functionality.

Confined space harness vs Standard harness Infographic

productdif.com

productdif.com