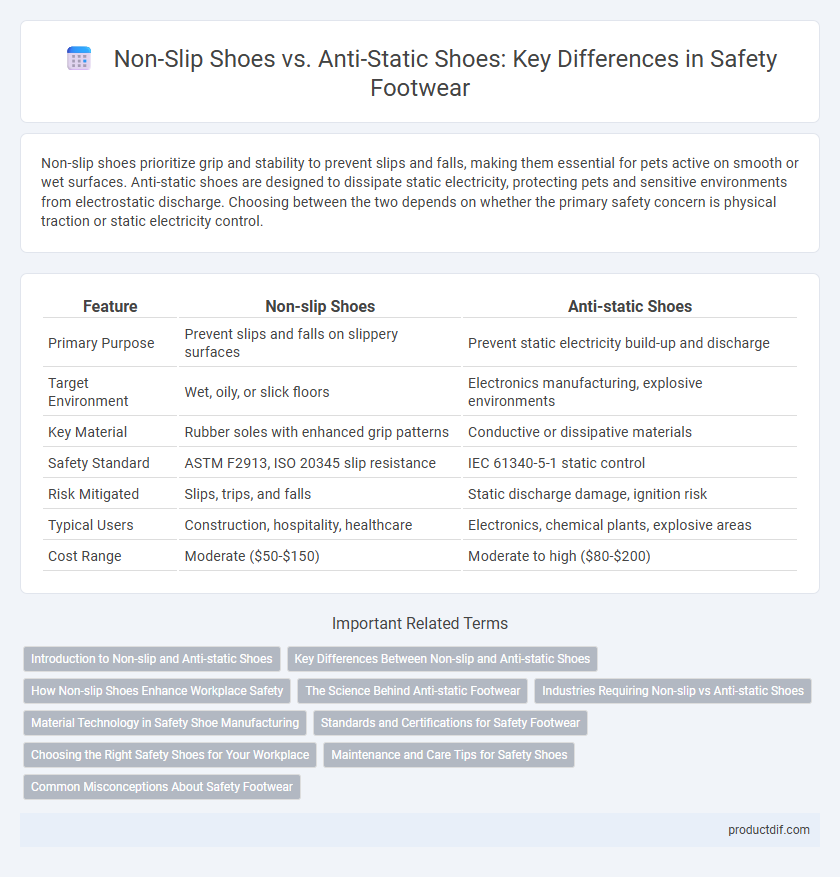

Non-slip shoes prioritize grip and stability to prevent slips and falls, making them essential for pets active on smooth or wet surfaces. Anti-static shoes are designed to dissipate static electricity, protecting pets and sensitive environments from electrostatic discharge. Choosing between the two depends on whether the primary safety concern is physical traction or static electricity control.

Table of Comparison

| Feature | Non-slip Shoes | Anti-static Shoes |

|---|---|---|

| Primary Purpose | Prevent slips and falls on slippery surfaces | Prevent static electricity build-up and discharge |

| Target Environment | Wet, oily, or slick floors | Electronics manufacturing, explosive environments |

| Key Material | Rubber soles with enhanced grip patterns | Conductive or dissipative materials |

| Safety Standard | ASTM F2913, ISO 20345 slip resistance | IEC 61340-5-1 static control |

| Risk Mitigated | Slips, trips, and falls | Static discharge damage, ignition risk |

| Typical Users | Construction, hospitality, healthcare | Electronics, chemical plants, explosive areas |

| Cost Range | Moderate ($50-$150) | Moderate to high ($80-$200) |

Introduction to Non-slip and Anti-static Shoes

Non-slip shoes feature specialized rubber soles designed to provide maximum traction on wet or oily surfaces, reducing the risk of slips and falls in hazardous work environments. Anti-static shoes are engineered with conductive materials that dissipate static electricity, preventing sparks that could ignite flammable substances, making them essential in electronics manufacturing and chemical industries. Both types of safety footwear play crucial roles in workplace safety by addressing different hazards related to slip resistance and static discharge.

Key Differences Between Non-slip and Anti-static Shoes

Non-slip shoes are designed with specialized rubber soles that provide enhanced traction on wet or oily surfaces, reducing the risk of slips and falls in environments like kitchens or warehouses. Anti-static shoes, on the other hand, feature conductive materials that dissipate static electricity to prevent sparks, which is critical in electronics manufacturing or explosive environments. The primary difference lies in their safety function: non-slip shoes focus on grip and stability, while anti-static shoes concentrate on static discharge protection.

How Non-slip Shoes Enhance Workplace Safety

Non-slip shoes significantly enhance workplace safety by providing superior traction on wet, oily, or slippery surfaces, reducing the risk of slips and falls. These shoes often feature specialized rubber soles or tread patterns designed to grip various floor types, essential in environments like kitchens, warehouses, and manufacturing plants. By minimizing slip-related accidents, non-slip shoes contribute to a safer work environment and help employers comply with occupational safety regulations.

The Science Behind Anti-static Footwear

Anti-static shoes incorporate conductive materials such as carbon or copper fibers within the sole to dissipate static electricity safely into the ground, preventing electronic component damage and reducing explosion risks in hazardous environments. These shoes maintain electrical continuity while providing insulation, ensuring wearer safety by controlling static discharge without compromising non-slip functionality. Unlike non-slip shoes that primarily focus on grip enhancement through specialized tread patterns and rubber compounds, anti-static footwear emphasizes electrostatic discharge management through scientifically engineered conductive pathways.

Industries Requiring Non-slip vs Anti-static Shoes

Non-slip shoes are essential in industries such as food service, healthcare, and hospitality where wet or greasy surfaces increase the risk of slips and falls. Anti-static shoes are critical in electronics manufacturing, chemical plants, and environments with flammable materials, as they prevent static discharge that could damage sensitive equipment or ignite hazardous substances. Choosing the appropriate footwear based on industry-specific hazards enhances workplace safety and compliance with occupational safety standards.

Material Technology in Safety Shoe Manufacturing

Non-slip shoes utilize advanced rubber compounds and tread patterns engineered for superior grip on wet or oily surfaces, enhancing workplace traction and reducing slip hazards. Anti-static shoes incorporate conductive fibers or carbon elements within the sole materials to safely dissipate static electricity, protecting sensitive electronic environments and personnel. Both shoe types employ cutting-edge material technologies tailored to specific safety needs, balancing durability, comfort, and functionality in industrial settings.

Standards and Certifications for Safety Footwear

Non-slip shoes are typically certified under ASTM F2913 to ensure slip resistance on various surfaces, while anti-static shoes meet ASTM F2413 standards for electrostatic discharge protection. Both types of safety footwear often adhere to ANSI and OSHA regulations, ensuring compliance with workplace safety requirements. Certifications like CSA Z195 in Canada and EN ISO 20345 in Europe also provide standardized testing for slip resistance and static control capabilities.

Choosing the Right Safety Shoes for Your Workplace

Non-slip shoes are designed with specialized rubber soles to provide enhanced traction on wet or oily surfaces, reducing the risk of slips and falls in environments such as kitchens or warehouses. Anti-static shoes prevent the buildup of static electricity by dissipating electrical charges safely, making them essential in electronics manufacturing or environments with flammable materials. Selecting the right safety shoes depends on your workplace hazards, prioritizing slip resistance for wet or greasy floors and static control for sensitive electronic or explosive settings.

Maintenance and Care Tips for Safety Shoes

Proper maintenance of non-slip shoes includes regular cleaning to remove dirt and grease from the outsole to maintain friction and prevent slips. Anti-static shoes require periodic inspection of the conductive sole and upper materials to ensure effective dissipation of static electricity. Storing safety shoes in a cool, dry place and avoiding harsh chemicals extends their lifespan and preserves their protective properties.

Common Misconceptions About Safety Footwear

Non-slip shoes are often mistakenly believed to provide adequate protection against static electricity, but they lack anti-static properties essential for environments sensitive to electrostatic discharge. Anti-static shoes, designed to dissipate static charge safely, do not inherently offer slip resistance and should not be relied upon for traction on slippery surfaces. Understanding the distinct functions and certifications of non-slip versus anti-static footwear, such as ASTM F2913 for slip resistance and ASTM F2413 for electrical properties, is crucial for selecting appropriate safety equipment.

Non-slip shoes vs Anti-static shoes Infographic

productdif.com

productdif.com