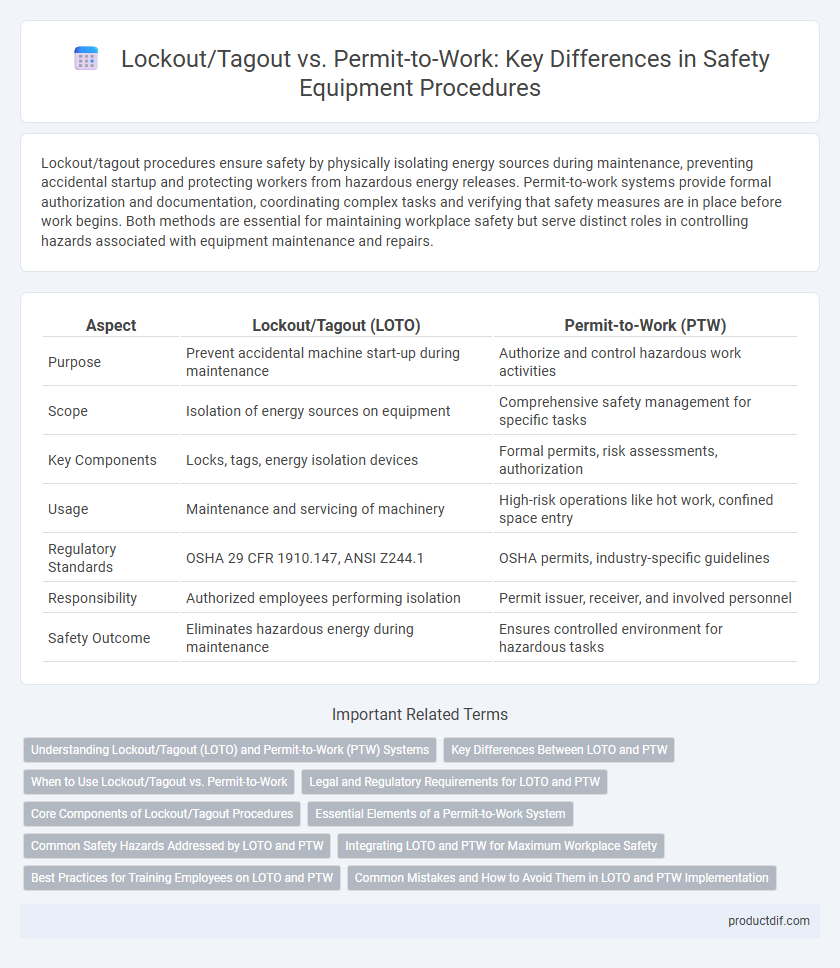

Lockout/tagout procedures ensure safety by physically isolating energy sources during maintenance, preventing accidental startup and protecting workers from hazardous energy releases. Permit-to-work systems provide formal authorization and documentation, coordinating complex tasks and verifying that safety measures are in place before work begins. Both methods are essential for maintaining workplace safety but serve distinct roles in controlling hazards associated with equipment maintenance and repairs.

Table of Comparison

| Aspect | Lockout/Tagout (LOTO) | Permit-to-Work (PTW) |

|---|---|---|

| Purpose | Prevent accidental machine start-up during maintenance | Authorize and control hazardous work activities |

| Scope | Isolation of energy sources on equipment | Comprehensive safety management for specific tasks |

| Key Components | Locks, tags, energy isolation devices | Formal permits, risk assessments, authorization |

| Usage | Maintenance and servicing of machinery | High-risk operations like hot work, confined space entry |

| Regulatory Standards | OSHA 29 CFR 1910.147, ANSI Z244.1 | OSHA permits, industry-specific guidelines |

| Responsibility | Authorized employees performing isolation | Permit issuer, receiver, and involved personnel |

| Safety Outcome | Eliminates hazardous energy during maintenance | Ensures controlled environment for hazardous tasks |

Understanding Lockout/Tagout (LOTO) and Permit-to-Work (PTW) Systems

Lockout/Tagout (LOTO) systems focus on isolating hazardous energy sources during maintenance by physically locking and tagging equipment to prevent accidental startup. Permit-to-Work (PTW) systems provide a formalized process for authorizing and supervising high-risk work activities through documented permits. Both systems are critical safety protocols designed to minimize workplace incidents, with LOTO emphasizing energy control and PTW ensuring compliance with safety procedures before work begins.

Key Differences Between LOTO and PTW

Lockout/tagout (LOTO) primarily focuses on isolating hazardous energy sources during machinery maintenance to prevent accidental startup, while permit-to-work (PTW) is a broader safety management system that controls various hazardous activities through documented authorization. LOTO involves physical locking and tagging of energy-isolating devices, ensuring equipment cannot be energized, whereas PTW requires formal permits to authorize and specify conditions for high-risk tasks like hot work or confined space entry. The key difference lies in LOTO's specific application to energy control versus PTW's comprehensive risk management across multiple work hazards.

When to Use Lockout/Tagout vs. Permit-to-Work

Lockout/Tagout procedures are essential during maintenance or servicing of machinery to ensure all energy sources are isolated and the equipment remains de-energized, preventing accidental startup. Permit-to-Work systems are used for high-risk work activities that require formal authorization and risk assessment before operations commence, such as confined space entry or hot work. Choosing between Lockout/Tagout and Permit-to-Work depends on the hazard type, with Lockout/Tagout addressing mechanical and electrical energy isolation, while Permit-to-Work manages broader safety controls and coordination of multiple risks.

Legal and Regulatory Requirements for LOTO and PTW

Lockout/tagout (LOTO) procedures are mandated by OSHA standard 29 CFR 1910.147, requiring employers to control hazardous energy during equipment servicing to prevent accidental startup. Permit-to-work (PTW) systems, governed by regulations such as OSHA, NFPA, and local safety codes, demand formal authorization and documentation before high-risk tasks, ensuring comprehensive hazard communication. Compliance with these legal frameworks ensures workplace safety, reducing risks of injury and regulatory penalties during maintenance and operational activities.

Core Components of Lockout/Tagout Procedures

Lockout/tagout procedures center on isolating hazardous energy sources through physical lock devices and highly visible tags to prevent accidental startup of machinery during maintenance. Core components include identifying all energy sources, notifying affected employees, applying locks and tags to energy-isolating devices, verifying isolation, and safely releasing lockout devices after work completion. This method ensures worker safety by controlling energy hazards more effectively than general permit-to-work systems.

Essential Elements of a Permit-to-Work System

A Permit-to-Work system ensures hazard identification, risk assessment, and authorization before starting high-risk tasks, integrating closely with Lockout/Tagout procedures to control energy sources. Essential elements include defined scope, clear responsibilities, communication protocols, and systematic documentation to maintain worker safety. This structured approach minimizes accidents by enforcing compliance and verifying isolation of hazardous energy during maintenance or operational activities.

Common Safety Hazards Addressed by LOTO and PTW

Lockout/tagout (LOTO) and permit-to-work (PTW) systems both address critical safety hazards such as unexpected equipment energization, hazardous energy release, and unauthorized work activities. LOTO specifically prevents accidental startup of machinery during maintenance by isolating energy sources, while PTW controls high-risk tasks like hot work, confined space entry, and electrical operations through formal authorization and monitoring. Together, these safety protocols mitigate risks of injury, exposure to hazardous substances, and equipment damage in industrial environments.

Integrating LOTO and PTW for Maximum Workplace Safety

Integrating Lockout/Tagout (LOTO) and Permit-to-Work (PTW) systems ensures comprehensive control over hazardous energy sources and work authorizations, reducing the risk of accidents and injuries. Combining LOTO's focus on isolating machinery energy with PTW's systematic checklists for hazardous tasks enhances compliance with OSHA regulations and industry safety standards like NFPA 70E. This integrated approach promotes clear communication among employees, rigorous hazard assessments, and verified procedural adherence, maximizing overall workplace safety.

Best Practices for Training Employees on LOTO and PTW

Effective training on Lockout/Tagout (LOTO) and Permit-to-Work (PTW) systems emphasizes hands-on practice, clear communication of procedural steps, and understanding of hazard identification. Employees should be educated on recognizing energy sources, applying locks and tags correctly, and following permit protocols to prevent accidental equipment startup. Regular refresher courses and scenario-based drills reinforce compliance and ensure workers maintain critical safety skills in hazardous environments.

Common Mistakes and How to Avoid Them in LOTO and PTW Implementation

Common mistakes in Lockout/Tagout (LOTO) and Permit-to-Work (PTW) implementation include incomplete isolation of energy sources, inadequate employee training, and failure to update or verify permits. To avoid these errors, ensure comprehensive energy control procedures are followed, provide regular and specific training sessions on both LOTO and PTW protocols, and implement strict verification steps before work begins. Consistent communication and thorough documentation between authorized personnel significantly reduce risks associated with energy isolation and task authorization.

Lockout/tagout vs Permit-to-work Infographic

productdif.com

productdif.com